Precautions for PCBA Sample Production

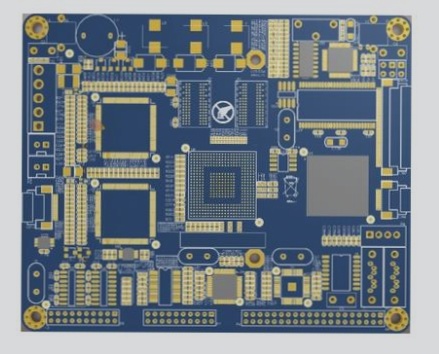

As the demand for PCBA samples rises, companies face challenges in production due to chip shortages and technical constraints. To stand out in the market, significant investments in resources are necessary. Dongguan Boyuan Electronics Co., Ltd. emphasizes the importance of fulfilling customer needs, regardless of order size.

Challenges in PCBA Sample Production

Many manufacturers hesitate to accept small orders due to startup fees and engineering costs. However, Boyuan Electronics is dedicated to meeting customer requirements promptly and precisely.

Key Precautions during PCBA Sample Production

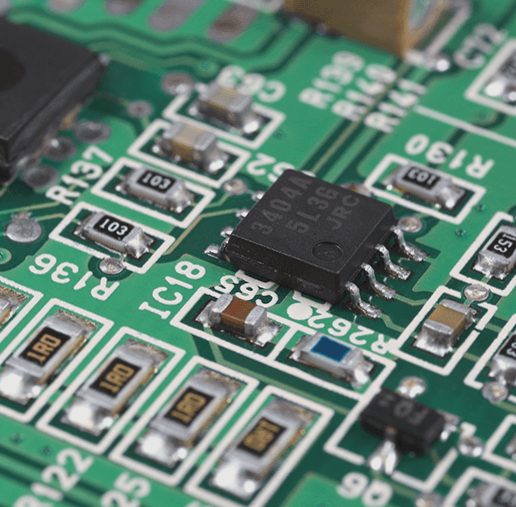

- Patch Processing: Precision is crucial in positioning surface components on PCBA. Maintain a clean work area by avoiding eating, drinking, or smoking during patch processing.

- Static Discharge Workbench: Regularly check the static discharge workbench to prevent damage to EOS/ESD components. Special care is needed for grounding and avoiding PCB stacking.

- Handling Soldering Surfaces: Prevent grease contamination on soldering surfaces by wearing gloves. Grease can reduce solderability and affect product quality.

- Hand Care During Production: Operators should refrain from using skin care products or silicone-containing detergents to maintain weldability. Follow cleaning protocols to ensure product quality and cost control.

Important Note: Attention to detail is crucial in PCBA sample production to meet customer expectations and ensure product quality.