Insider Insights into the PCB Circuit Board Industry

-

Inadequate Production Technology

Smaller factories often face challenges due to financial constraints, leading to inadequate production technology. Circuit boards require advanced processes like mechanics, electroplating, and chemical engineering. Strict procedural adherence and specialized inspection equipment are essential for ensuring quality standards.

-

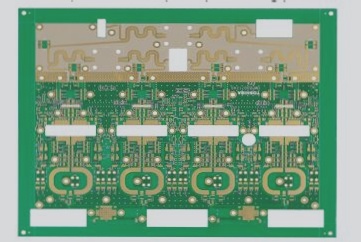

Production Equipment

Outdated PCB production equipment hinders product quality. Investing in efficient machinery is crucial for enhancing circuit board quality. As technology advances, equipment becomes faster and more sophisticated, albeit pricier. Small factories may struggle to afford advanced machinery, increasing their reliance on manual labor and complicating management.

-

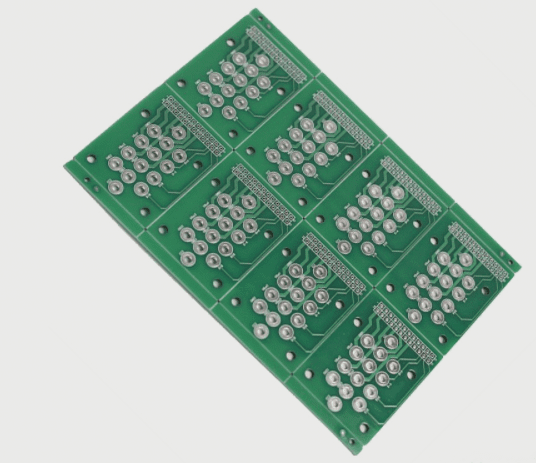

Quality of Raw Materials

The reliability of PCB circuit boards heavily relies on the quality of raw materials. Using subpar materials can lead to defects like cracks, delamination, and bubbles. Some manufacturers mix new and recycled materials to reduce costs, posing hidden risks. Quality issues from faulty substrates can result in significant losses and damage a company’s reputation.

-

Disorganized Management

Managing PCB production processes efficiently is challenging due to their complexity and long lead times. Accumulating industry experience and leveraging digital tools for scientific management practices are crucial. With the Internet’s rapid growth, management departments must adapt to modern practices in traditional circuit board manufacturing.

If you require PCB manufacturing services, feel free to contact us.