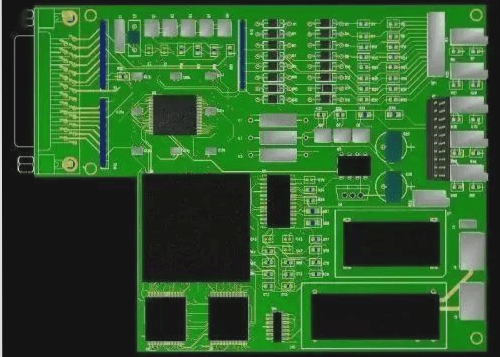

The development of today’s technology and industry has brought about tremendous changes in social life. With the gradual popularization of the Internet of Things, big data, and AI applications, the development and application requirements for PCB drilling have also evolved significantly. This article will explore the factors that should be considered for PCB drilling.

1. Equipment factors: Excessive spindle runout and uneven wear on the presser foot can cause crushing damage to the aluminum sheet during drilling, impacting the dust collection efficiency. In severe cases, drill chips may accumulate beneath the aluminum sheet, leading to inadequate dust suction strength.

2. Material issues: Serious scratches or creases on the aluminum sheet of the cover and bottom plate can cause drill bits, especially Microdrill bits, to break at these defects. Poor-quality bottom material with impurities, oversized aluminum sheets, or arched aluminum sheets after adhesive tape application can also increase presser foot wear and worsen dust collection. Conversely, undersized aluminum sheets may lead to drilling near the edges or tape.

3. Operating Factors

During the board loading process, if the work surface (pad board), bottom board, production board, and cover board are not properly cleaned, debris can cause the drill bit to break. Additionally, if the drilling depth is too great, chip removal conditions will deteriorate.

4. Drilling Nozzle Control

A drill nozzle with too short a cutting length results in poor chip removal. Frequent regrinding of the drill tip shortens its effective cutting length, leading to excessive wear and decreased chip removal efficiency. Inadequate drill bit control, including pick-up, ringset making, and grinding, exacerbates the problem.

The PCB drilling process involves stacking multiple printed boards and drilling them simultaneously with the intended hole size. The drill size (e.g., size 9) considers that some plating metal will flow into the hole. Holes that are fully copper-plated and those that are not will be plated differently depending on the environment.

PCB manufacturers set a minimum drilling hole size based on the board thickness. The thinner the board, the smaller the drill head required. This is expressed as a plate thickness-to-aperture ratio, which includes both the rough-machined and finished ratios. The rough-machined ratio reflects the actual drilled hole size, while the finished ratio accounts for standard electroplating. Designers must choose whether to use the rough-machined or finished ratio. The board thickness-to-aperture ratio is limited by the smallest available drilling machine, and this ratio cannot be updated beyond the capabilities of the smallest drilling machine.

Secondary Drilling

If a hole is located in a copper area but should not be electroplated, secondary drilling is necessary. The area around an unplated hole, known as unsupported land, may need additional electroplating to prevent deformation, dissipate heat, and avoid solder bumps. This increases the overall cost, as it requires additional electroplating. Options include electroplating all pairs of holes or reserving a “clean area” around the hole and copper area to avoid secondary drilling.

1. Equipment factors: Excessive spindle runout and uneven wear on the presser foot can cause crushing damage to the aluminum sheet during drilling, impacting the dust collection efficiency. In severe cases, drill chips may accumulate beneath the aluminum sheet, leading to inadequate dust suction strength.

2. Material issues: Serious scratches or creases on the aluminum sheet of the cover and bottom plate can cause drill bits, especially Microdrill bits, to break at these defects. Poor-quality bottom material with impurities, oversized aluminum sheets, or arched aluminum sheets after adhesive tape application can also increase presser foot wear and worsen dust collection. Conversely, undersized aluminum sheets may lead to drilling near the edges or tape.

3. Operating Factors

During the board loading process, if the work surface (pad board), bottom board, production board, and cover board are not properly cleaned, debris can cause the drill bit to break. Additionally, if the drilling depth is too great, chip removal conditions will deteriorate.

4. Drilling Nozzle Control

A drill nozzle with too short a cutting length results in poor chip removal. Frequent regrinding of the drill tip shortens its effective cutting length, leading to excessive wear and decreased chip removal efficiency. Inadequate drill bit control, including pick-up, ringset making, and grinding, exacerbates the problem.

The PCB drilling process involves stacking multiple printed boards and drilling them simultaneously with the intended hole size. The drill size (e.g., size 9) considers that some plating metal will flow into the hole. Holes that are fully copper-plated and those that are not will be plated differently depending on the environment.

PCB manufacturers set a minimum drilling hole size based on the board thickness. The thinner the board, the smaller the drill head required. This is expressed as a plate thickness-to-aperture ratio, which includes both the rough-machined and finished ratios. The rough-machined ratio reflects the actual drilled hole size, while the finished ratio accounts for standard electroplating. Designers must choose whether to use the rough-machined or finished ratio. The board thickness-to-aperture ratio is limited by the smallest available drilling machine, and this ratio cannot be updated beyond the capabilities of the smallest drilling machine.

Secondary Drilling

If a hole is located in a copper area but should not be electroplated, secondary drilling is necessary. The area around an unplated hole, known as unsupported land, may need additional electroplating to prevent deformation, dissipate heat, and avoid solder bumps. This increases the overall cost, as it requires additional electroplating. Options include electroplating all pairs of holes or reserving a “clean area” around the hole and copper area to avoid secondary drilling.