Key Principles for PCB Maintenance

When it comes to PCB maintenance, industry professionals follow specific guidelines to ensure an organized and systematic approach to repair work.

Principle 1: Prioritize Quantity

Start by visually inspecting the circuit board for any disconnections, short circuits, or potential fractures. Pay close attention to components like resistors, capacitors, inductors, and diodes for signs of damage. Check for previous repairs and any issues like cold solder joints or leaks. Use a multimeter to measure resistance and diagnose any damaged components. Make sure to power up the board correctly for accurate diagnosis and repair.

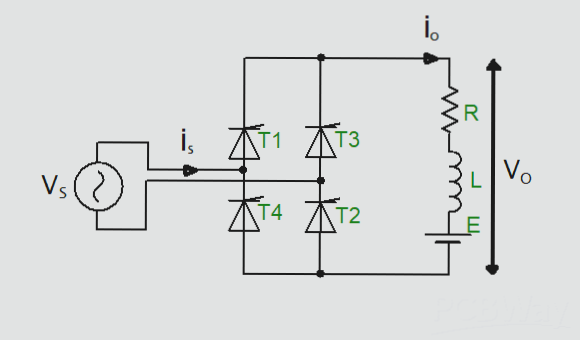

Voltage Value Caution

Incorrect voltage values can damage the circuit board and introduce new issues. Monitor component temperatures for potential problems during repair.

If resistance values are normal, use a multimeter to test other parts like the MOSFET and switches. Avoid overcomplicating issues that basic test tools can diagnose easily.

Principle 2: External First, Then Internal

Refer to a similar working circuit board for comparison. Use a double-edge VI curve scanning function to test and compare components. Start testing from the input port and move through test points to detect issues like capacitor leakage.

Principle 3: Start with Difficulties, End with the Easier Ones

Prioritize preliminary repairs and adjustments before conducting online function tests. Prepare by short-circuiting the crystal oscillator and disconnecting large capacitors to minimize interference. Log and re-test components during online testing, removing any failing devices. Consider using test instruments for practical component testing.

If you require PCB manufacturing services, feel free to contact us.