PCB Design Best Practices

When designing a PCB, it is crucial to adhere to specific requirements and follow established guidelines to ensure optimal performance. Here are some basic principles to consider:

1. Collaboration and Specification

- Engage with relevant personnel to meet requirements for structure, signal integrity, manufacturing, testability, and electromagnetic compatibility.

2. Component Placement

- Position critical components like connectors and indicator lights based on structural diagrams.

3. Prohibited Areas

- Designate areas where wiring and layout are restricted based on device requirements.

4. Process Flow Selection

- Consider PCB performance and manufacturing efficiency when choosing the process flow.

5. Layout Optimization

- Minimize wiring length, separate signal types, and ensure proper spacing for components.

6. Modular Layout

- Implement a symmetrical modular layout for identical circuit sections.

7. Grid Settings

- Use recommended grid sizes for layout settings to ensure proper spacing.

8. Wiring Considerations

- Choose wire width and spacing wisely based on process conditions and density requirements.

9. Line Orientation

- Orient adjacent wiring layers to minimize parasitic capacitance.

10. Signal Integrity

- Keep printed trace wiring short for high-frequency signals and sensitive lines.

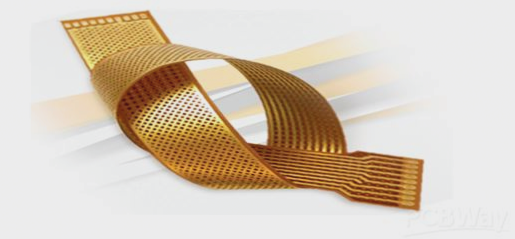

For a detailed guide on PCB design principles and best practices, refer to the image below:

Trace Width and Spacing Recommendations

1. Line Width/Spacing

- Recommended line width/spacing is ≥5mil/5mil, with a minimum usable width/spacing of 4mil/4mil.

2. Distance Guidelines

- Maintain appropriate distances between traces, pads, and solder mask openings to prevent interference.

Safety Distance and Routing

1. Edge Clearance

- Ensure a safety distance of >20mil between traces and the board edge to prevent short circuits.

2. Grounding Considerations

- Maintain proper separation between grounding elements and the board edge to avoid interference.

3. Restricted Wiring Zones

- Avoid routing in areas where metal components directly contact the PCB to prevent potential issues.

Key Considerations for PCB Layout Optimization

Shortest Distance Between Trace and Non-Metallized Hole

When designing a PCB layout, it is crucial to maintain the shortest distance between traces and non-metallized holes to prevent signal interference and ensure signal integrity.

Essential Principles of Multi-Layer PCB Layout

- The bottom layer, acting as the ground plane, shields the device and serves as a reference for surface wiring.

- Position signal layers close to the ground plane to minimize interference.

- Avoid placing adjacent signal layers to prevent crosstalk.

- Proximity of the main power supply is vital for efficient operation.

- Adopt a symmetrical design for uniformity in dielectric and copper foil thickness.

Best Practices for Silk Screen Design

- Ensure legibility by using a silk screen line width exceeding 5 mils and a height of at least 50 mils.

- Avoid overlapping silk screen with pads or reference points.

- Default silk screen ink color is white; specify any special requirements in the drilling file.

- Customize silk screen content in high-density PCBs based on specific needs.

- Arrange silk-screened strings from left to right and bottom to top for clarity.

If you require PCB manufacturing services, feel free to contact us.