Surface Mount Technology (SMT) and Surface Mount Devices (SMD) in PCB Assembly

SMT, short for surface mount technology, is a widely used skill and process in the electronic assembly industry. SMD components, available in various shapes like rectangular sheets or cylindrical rows, are attached to PCB circuits using reflow soldering. This process involves distributing solder paste on PCB circuits and then melting it to create connections.

No-Clean Process in SMT

SMT and SMD utilize a no-clean process, reducing the need for product cleaning and minimizing environmental pollution. Traditional cleaning methods using organic solvents can harm water quality, land, and air. Implementing a no-clean process can lower operation and maintenance costs while preserving product quality by preventing corrosion.

Flux Residue Control

Controlling flux residue levels is crucial to meet appearance standards and avoid visual inspection requirements. Enhancements in residual flux improve electrical functionality, safeguarding products from potential damage. International safety assessments have confirmed the stability and non-corrosive nature of flux chemicals in SMT machines.

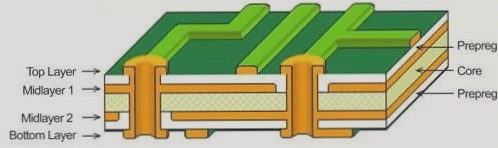

Product Structure and Material Management

Product structure tables, also known as “recipes” or “element tables,” play a vital role in material resource planning systems. These tables encompass various materials used in production, including finished products, raw materials, and accessories, ensuring efficient inventory management.

- Efficient SMT and SMD processes

- Environmental benefits of no-clean technology

- Quality control through flux residue management

- Effective material resource planning