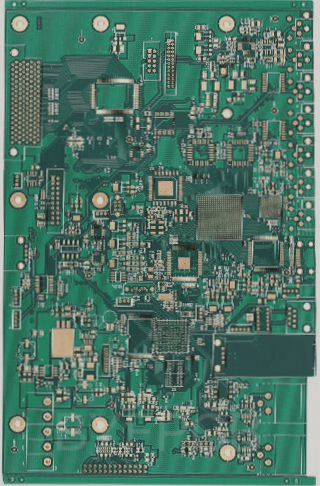

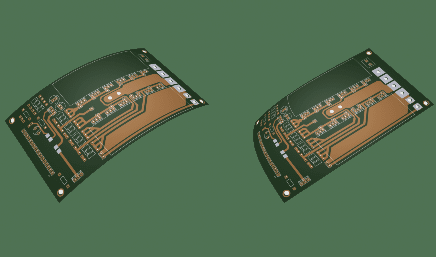

When discussing FPC cables, it’s essential to understand what FPC stands for. FPC can be categorized into various types based on function, including FPC antennas, FPC touch screens, and FPC capacitive screens. Among these, FPC cables are notable as they consist of a group of connecting cables that can bend to a certain extent.

2. The function and purpose of the FPC cable

The primary function of the FPC cable is to connect two related components or products. Many modern devices utilize flat cables due to their flexibility. FPC flat cables are commonly found in products such as printers, smartphones, and laptops.

3. FPC cable composition and parameters

As a type of FPC, the composition of an FPC cable mirrors that of FPC itself. Typically elongated, both ends feature pluggable pins for direct connection to connectors or soldering to products. The central section usually contains a circuit, and to ensure the necessary flexibility, the base material is often made of rolled copper, which is both durable and pliable.

**Cable Parameters:**

The minimum line width and line spacing are 3 mil/3 mil;

The smallest finished wire hole measures 0.15 mm.

**Fourth, FPC Wiring Process**

The surface treatment process typically used for FPC cables is gold, with occasional use of anti-oxidation treatments. However, the anti-oxidation process cannot withstand high temperatures and has poorer environmental endurance compared to immersion gold, despite the similar costs of both methods. Consequently, immersion gold technology is predominantly adopted. Additionally, processes such as tin plating and tin spraying exist, but the temperature resistance of FPC generally remains below 280 degrees Celsius, while tin spraying exceeds 300 degrees Celsius. Given the lower hardness of the solder paste, tin spraying is rarely employed.

**Five, Advantages and Disadvantages of FPC Cable**

**Advantages:**

Using FPC can significantly reduce the volume and weight of electronic products, making it ideal for the development of high-density, miniaturized, and highly reliable electronic devices. As a result, FPC has found extensive applications in aerospace, military, mobile communications, laptops, computer peripherals, PDAs, digital cameras, and other fields. Furthermore, FPC can be arranged flexibly according to spatial layout requirements, allowing for movement and expansion in three-dimensional space, thereby facilitating the integration of component assembly and wire connections.

**Disadvantages:**

Cost considerations are paramount during product production. Since flexible FPC is specifically designed for unique applications, the initial circuit design, wiring, and photographic masters incur higher costs. Unless there is a distinct necessity for soft FPC, it is generally advisable to avoid its use in small-scale applications. Additionally, given the significant investment in development, ongoing maintenance is crucial, necessitating that soldering and rework be performed by trained personnel.

**Storage of FPC Cable:**

Unlike other products, FPC flexible circuit boards are not directly exposed to air and water. So, how should we store this product correctly? After reviewing the following guidelines, you’ll find the answer.

First, the vacuum integrity of the FPC flexible circuit board must be preserved. When packaging, bubble wrap should be placed against the box’s interior, as it effectively absorbs moisture, playing a crucial role in moisture prevention. Additionally, moisture-absorbing beads are essential.

Second, once sealed, the box should be stored in a dry, well-ventilated area, elevated from the ground, and shielded from sunlight. The optimal warehouse temperature should be maintained at 23 ± 3 degrees Celsius with 55 ± 10% RH. Under these conditions, PCB boards with surface treatments such as immersion gold, electro-gold, spray tin, and silver plating can generally be stored for six months. Surface-treated PCB boards like Shen tin and OSP can typically be stored for three months.

—

Feel free to reach out if you need any further modifications!