Common Causes of Solder Joint Invalidation in PCBA Processing

- Improper positioning of electronic devices: issues with coating, environmental contamination, and air oxidation can lead to solder joint problems.

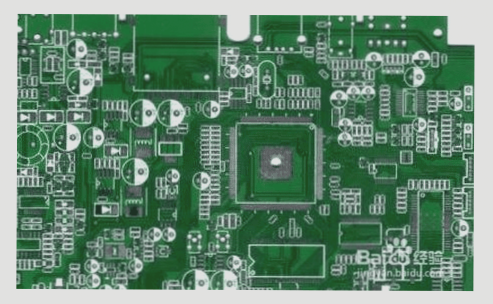

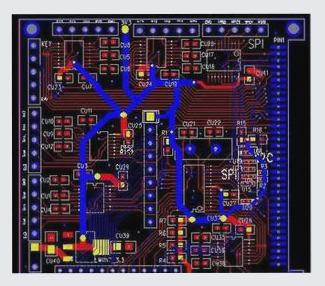

Factors Affecting PCB Welding Layer Quality

- Issues with coating, environmental contamination, air oxidation, and thermal expansion and contraction can impact the quality of the PCB welding layer.

Quality Control Measures for PCBA Processing

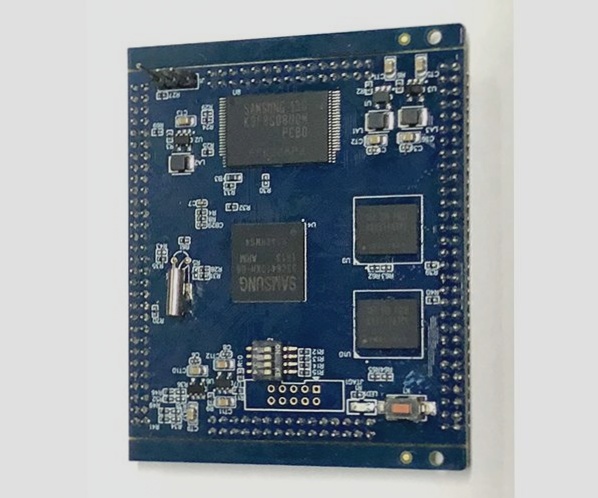

- Conducting a pre-production meeting to analyze PCB Gerber files and submit manufacturability reports tailored to customer requirements can help prevent quality issues.

- Strict control over procurement channels for electronic components is crucial to avoid using substandard materials.

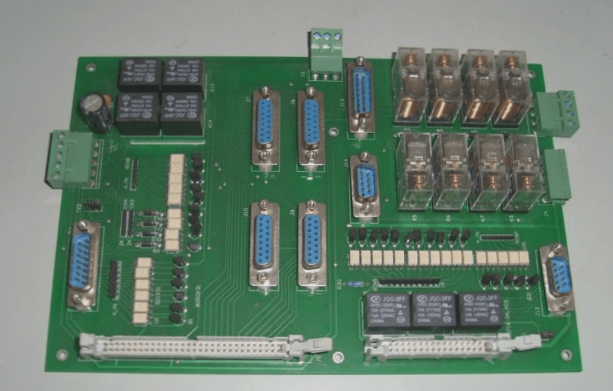

- Ensuring proper SMT assembly with a focus on solder paste printing and reflow oven temperature control systems is essential for high-quality PCBA processing.

- Optimizing wave soldering molds design during the plug-in process can enhance productivity.

- Performing thorough board testing, including ICT, FCT, burn-in testing, temperature and humidity testing, and drop testing, is important for ensuring product quality.

Feel free to reach out if you require any further assistance!