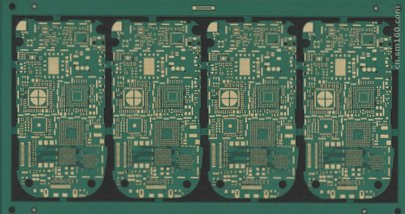

1 20-layer PCB is a multi-layer printed circuit board with 20 layers of copper, alternating with a substrate called epoxy resin.

2 Some of the main materials used in manufacturing 20-layer PCBs include wire mesh, substrate, solder mask, and copper.

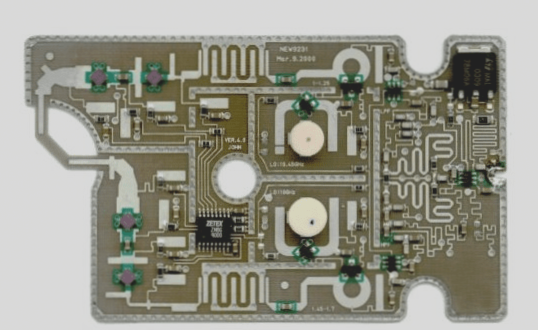

Application of 20-layer PCB 1. Consumer electronics 20-layer circuit boards are very useful in manufacturing electronic products commonly used in offices or homes. These products include calculators, music players, watches, smartphones, and more. It can also be used to make electric kettles, washing machines, LED light bulbs and kitchen appliances. 2. Communication electronic products 20 layer PCB is very useful in the manufacturing of GPRS, radar electronics, communication towers, computer servers and satellites. Other areas where 20-layer PCBs are used include low-noise amplifiers, filters, mixers, power amplifiers, sonar antennas, phase-locked loops and attenuators. 3. Computer 20-layer PCBs are very useful in the production of computers and other components, such as power supplies, graphics cards, EEPROMs and motherboards. Others include ADCs, computer mice, keyboards, and image processing circuits. 4. Automation Operations carried out in industry are often susceptible to pressure, dust, temperature, humidity and shock, which is why 20-layer PCBs are very reliable. Additionally, different industrial applications such as automobile manufacturing, robotics, and conveyor belts use this type of PCB. 5. Medical equipment 20-layer PCBs are very useful in testing and monitoring of medical devices. In addition, 20-layer PCB can also be used for blood pressure measurement equipment, infrared temperature monitoring equipment, blood sugar testing electronic equipment, etc. 6. Defense, aerospace and military 20-layer circuit boards are useful components for military machines such as surveillance, radar, ground and air drones. In addition, they can be used in electromagnetic guns, navigation systems, artificial intelligence and automatic cannons. Layered structure of 20-layer PCB The stacking of 20-layer PCB refers to the formation of 20 layers of insulation and copper layers into a printed circuit board before the layout of the circuit board. These coverings play an important role in reducing external interference from the circuit. Additionally, crosstalk, impedance, and radiation issues that arise in high-speed PCB layers can be mitigated through lamination. 20-layer PCB manufacturing process 1. Imaging process Here you can implement digital designs on your circuit board. Next, it will be transferred from your software to the board. 2. Etching process This process involves using industrial solvents to remove excess metal from printed circuit boards. 3. Suppression Here you use a tablet press to put together a 20-layer PCB. Finally, you generate a circuit board. 4. Processing In the process of processing this type of printed circuit board, you will need to drill through holes and holes. This drilling ensures connections between all layers of the PCB. 5. Copper plating During the manufacturing process, you need to apply metal to complete the vias. Manufacturing steps of 20-layer PCB 1. The first step is to analyze the requirements of the circuit board and then select the components of the printed circuit board. 2. Secondly, design the front end within the system 3. Next is the initialization of the lithography tool. You can do this by transferring the software image to the printed circuit board. 4. The fourth step is to print the inner layer of the PCB 5. The next step is to remove excess copper from the board by etching 6. The sixth step involves aligning the inner layers of the PCB. You can align it by punching holes. 7. Finally, perform an optical inspection of your completed PCB. Design specifications for 20-layer PCB 1. PCB must operate at high speed and high volume 2. Its heat resistance must be very good 3. This type of PCB must be ideal for making powerful, portable and even small devices 4. There must be 20 alternating layers of copper base Advantages of 20-layer PCB 1. High assembly density, small size and light weight, meeting the needs of miniaturization of electronic equipment. 2. Due to the high assembly density, wiring between various components (including components) is reduced, installation is simple, and reliability is high. 3. Due to the repeatability and consistency of graphics, wiring and assembly errors are reduced, saving equipment maintenance, debugging and inspection time. 4. It can increase the number of wiring layers, thereby increasing design flexibility. 5. It can form a circuit with a certain impedance and form a high-speed transmission circuit. 6. Circuit and magnetic shielding layers can be set, and metal core heat dissipation layers can also be set up to meet special functional requirements such as shielding and heat dissipation. Due to its flexible design, stable and reliable electrical performance and superior economic performance, 20-layer PCB has been widely used in the production and manufacturing of electronic products. With the continuous development of electronic technology and the increasing requirements for electronic equipment in industries such as computers, healthcare, and aerospace, circuit boards are moving towards reduced volume, reduced mass, and increased density. Due to the limitations of available space, it has been impossible to further increase the assembly density of single- and double-layer printed boards. Therefore, multilayer circuit boards with more layers and higher assembly density must be considered.

Application of 20-layer PCB 1. Consumer electronics 20-layer circuit boards are very useful in manufacturing electronic products commonly used in offices or homes. These products include calculators, music players, watches, smartphones, and more. It can also be used to make electric kettles, washing machines, LED light bulbs and kitchen appliances. 2. Communication electronic products 20 layer PCB is very useful in the manufacturing of GPRS, radar electronics, communication towers, computer servers and satellites. Other areas where 20-layer PCBs are used include low-noise amplifiers, filters, mixers, power amplifiers, sonar antennas, phase-locked loops and attenuators. 3. Computer 20-layer PCBs are very useful in the production of computers and other components, such as power supplies, graphics cards, EEPROMs and motherboards. Others include ADCs, computer mice, keyboards, and image processing circuits. 4. Automation Operations carried out in industry are often susceptible to pressure, dust, temperature, humidity and shock, which is why 20-layer PCBs are very reliable. Additionally, different industrial applications such as automobile manufacturing, robotics, and conveyor belts use this type of PCB. 5. Medical equipment 20-layer PCBs are very useful in testing and monitoring of medical devices. In addition, 20-layer PCB can also be used for blood pressure measurement equipment, infrared temperature monitoring equipment, blood sugar testing electronic equipment, etc. 6. Defense, aerospace and military 20-layer circuit boards are useful components for military machines such as surveillance, radar, ground and air drones. In addition, they can be used in electromagnetic guns, navigation systems, artificial intelligence and automatic cannons. Layered structure of 20-layer PCB The stacking of 20-layer PCB refers to the formation of 20 layers of insulation and copper layers into a printed circuit board before the layout of the circuit board. These coverings play an important role in reducing external interference from the circuit. Additionally, crosstalk, impedance, and radiation issues that arise in high-speed PCB layers can be mitigated through lamination. 20-layer PCB manufacturing process 1. Imaging process Here you can implement digital designs on your circuit board. Next, it will be transferred from your software to the board. 2. Etching process This process involves using industrial solvents to remove excess metal from printed circuit boards. 3. Suppression Here you use a tablet press to put together a 20-layer PCB. Finally, you generate a circuit board. 4. Processing In the process of processing this type of printed circuit board, you will need to drill through holes and holes. This drilling ensures connections between all layers of the PCB. 5. Copper plating During the manufacturing process, you need to apply metal to complete the vias. Manufacturing steps of 20-layer PCB 1. The first step is to analyze the requirements of the circuit board and then select the components of the printed circuit board. 2. Secondly, design the front end within the system 3. Next is the initialization of the lithography tool. You can do this by transferring the software image to the printed circuit board. 4. The fourth step is to print the inner layer of the PCB 5. The next step is to remove excess copper from the board by etching 6. The sixth step involves aligning the inner layers of the PCB. You can align it by punching holes. 7. Finally, perform an optical inspection of your completed PCB. Design specifications for 20-layer PCB 1. PCB must operate at high speed and high volume 2. Its heat resistance must be very good 3. This type of PCB must be ideal for making powerful, portable and even small devices 4. There must be 20 alternating layers of copper base Advantages of 20-layer PCB 1. High assembly density, small size and light weight, meeting the needs of miniaturization of electronic equipment. 2. Due to the high assembly density, wiring between various components (including components) is reduced, installation is simple, and reliability is high. 3. Due to the repeatability and consistency of graphics, wiring and assembly errors are reduced, saving equipment maintenance, debugging and inspection time. 4. It can increase the number of wiring layers, thereby increasing design flexibility. 5. It can form a circuit with a certain impedance and form a high-speed transmission circuit. 6. Circuit and magnetic shielding layers can be set, and metal core heat dissipation layers can also be set up to meet special functional requirements such as shielding and heat dissipation. Due to its flexible design, stable and reliable electrical performance and superior economic performance, 20-layer PCB has been widely used in the production and manufacturing of electronic products. With the continuous development of electronic technology and the increasing requirements for electronic equipment in industries such as computers, healthcare, and aerospace, circuit boards are moving towards reduced volume, reduced mass, and increased density. Due to the limitations of available space, it has been impossible to further increase the assembly density of single- and double-layer printed boards. Therefore, multilayer circuit boards with more layers and higher assembly density must be considered.

2 Some of the main materials used in manufacturing 20-layer PCBs include wire mesh, substrate, solder mask, and copper.

Application of 20-layer PCB 1. Consumer electronics 20-layer circuit boards are very useful in manufacturing electronic products commonly used in offices or homes. These products include calculators, music players, watches, smartphones, and more. It can also be used to make electric kettles, washing machines, LED light bulbs and kitchen appliances. 2. Communication electronic products 20 layer PCB is very useful in the manufacturing of GPRS, radar electronics, communication towers, computer servers and satellites. Other areas where 20-layer PCBs are used include low-noise amplifiers, filters, mixers, power amplifiers, sonar antennas, phase-locked loops and attenuators. 3. Computer 20-layer PCBs are very useful in the production of computers and other components, such as power supplies, graphics cards, EEPROMs and motherboards. Others include ADCs, computer mice, keyboards, and image processing circuits. 4. Automation Operations carried out in industry are often susceptible to pressure, dust, temperature, humidity and shock, which is why 20-layer PCBs are very reliable. Additionally, different industrial applications such as automobile manufacturing, robotics, and conveyor belts use this type of PCB. 5. Medical equipment 20-layer PCBs are very useful in testing and monitoring of medical devices. In addition, 20-layer PCB can also be used for blood pressure measurement equipment, infrared temperature monitoring equipment, blood sugar testing electronic equipment, etc. 6. Defense, aerospace and military 20-layer circuit boards are useful components for military machines such as surveillance, radar, ground and air drones. In addition, they can be used in electromagnetic guns, navigation systems, artificial intelligence and automatic cannons. Layered structure of 20-layer PCB The stacking of 20-layer PCB refers to the formation of 20 layers of insulation and copper layers into a printed circuit board before the layout of the circuit board. These coverings play an important role in reducing external interference from the circuit. Additionally, crosstalk, impedance, and radiation issues that arise in high-speed PCB layers can be mitigated through lamination. 20-layer PCB manufacturing process 1. Imaging process Here you can implement digital designs on your circuit board. Next, it will be transferred from your software to the board. 2. Etching process This process involves using industrial solvents to remove excess metal from printed circuit boards. 3. Suppression Here you use a tablet press to put together a 20-layer PCB. Finally, you generate a circuit board. 4. Processing In the process of processing this type of printed circuit board, you will need to drill through holes and holes. This drilling ensures connections between all layers of the PCB. 5. Copper plating During the manufacturing process, you need to apply metal to complete the vias. Manufacturing steps of 20-layer PCB 1. The first step is to analyze the requirements of the circuit board and then select the components of the printed circuit board. 2. Secondly, design the front end within the system 3. Next is the initialization of the lithography tool. You can do this by transferring the software image to the printed circuit board. 4. The fourth step is to print the inner layer of the PCB 5. The next step is to remove excess copper from the board by etching 6. The sixth step involves aligning the inner layers of the PCB. You can align it by punching holes. 7. Finally, perform an optical inspection of your completed PCB. Design specifications for 20-layer PCB 1. PCB must operate at high speed and high volume 2. Its heat resistance must be very good 3. This type of PCB must be ideal for making powerful, portable and even small devices 4. There must be 20 alternating layers of copper base Advantages of 20-layer PCB 1. High assembly density, small size and light weight, meeting the needs of miniaturization of electronic equipment. 2. Due to the high assembly density, wiring between various components (including components) is reduced, installation is simple, and reliability is high. 3. Due to the repeatability and consistency of graphics, wiring and assembly errors are reduced, saving equipment maintenance, debugging and inspection time. 4. It can increase the number of wiring layers, thereby increasing design flexibility. 5. It can form a circuit with a certain impedance and form a high-speed transmission circuit. 6. Circuit and magnetic shielding layers can be set, and metal core heat dissipation layers can also be set up to meet special functional requirements such as shielding and heat dissipation. Due to its flexible design, stable and reliable electrical performance and superior economic performance, 20-layer PCB has been widely used in the production and manufacturing of electronic products. With the continuous development of electronic technology and the increasing requirements for electronic equipment in industries such as computers, healthcare, and aerospace, circuit boards are moving towards reduced volume, reduced mass, and increased density. Due to the limitations of available space, it has been impossible to further increase the assembly density of single- and double-layer printed boards. Therefore, multilayer circuit boards with more layers and higher assembly density must be considered.

Application of 20-layer PCB 1. Consumer electronics 20-layer circuit boards are very useful in manufacturing electronic products commonly used in offices or homes. These products include calculators, music players, watches, smartphones, and more. It can also be used to make electric kettles, washing machines, LED light bulbs and kitchen appliances. 2. Communication electronic products 20 layer PCB is very useful in the manufacturing of GPRS, radar electronics, communication towers, computer servers and satellites. Other areas where 20-layer PCBs are used include low-noise amplifiers, filters, mixers, power amplifiers, sonar antennas, phase-locked loops and attenuators. 3. Computer 20-layer PCBs are very useful in the production of computers and other components, such as power supplies, graphics cards, EEPROMs and motherboards. Others include ADCs, computer mice, keyboards, and image processing circuits. 4. Automation Operations carried out in industry are often susceptible to pressure, dust, temperature, humidity and shock, which is why 20-layer PCBs are very reliable. Additionally, different industrial applications such as automobile manufacturing, robotics, and conveyor belts use this type of PCB. 5. Medical equipment 20-layer PCBs are very useful in testing and monitoring of medical devices. In addition, 20-layer PCB can also be used for blood pressure measurement equipment, infrared temperature monitoring equipment, blood sugar testing electronic equipment, etc. 6. Defense, aerospace and military 20-layer circuit boards are useful components for military machines such as surveillance, radar, ground and air drones. In addition, they can be used in electromagnetic guns, navigation systems, artificial intelligence and automatic cannons. Layered structure of 20-layer PCB The stacking of 20-layer PCB refers to the formation of 20 layers of insulation and copper layers into a printed circuit board before the layout of the circuit board. These coverings play an important role in reducing external interference from the circuit. Additionally, crosstalk, impedance, and radiation issues that arise in high-speed PCB layers can be mitigated through lamination. 20-layer PCB manufacturing process 1. Imaging process Here you can implement digital designs on your circuit board. Next, it will be transferred from your software to the board. 2. Etching process This process involves using industrial solvents to remove excess metal from printed circuit boards. 3. Suppression Here you use a tablet press to put together a 20-layer PCB. Finally, you generate a circuit board. 4. Processing In the process of processing this type of printed circuit board, you will need to drill through holes and holes. This drilling ensures connections between all layers of the PCB. 5. Copper plating During the manufacturing process, you need to apply metal to complete the vias. Manufacturing steps of 20-layer PCB 1. The first step is to analyze the requirements of the circuit board and then select the components of the printed circuit board. 2. Secondly, design the front end within the system 3. Next is the initialization of the lithography tool. You can do this by transferring the software image to the printed circuit board. 4. The fourth step is to print the inner layer of the PCB 5. The next step is to remove excess copper from the board by etching 6. The sixth step involves aligning the inner layers of the PCB. You can align it by punching holes. 7. Finally, perform an optical inspection of your completed PCB. Design specifications for 20-layer PCB 1. PCB must operate at high speed and high volume 2. Its heat resistance must be very good 3. This type of PCB must be ideal for making powerful, portable and even small devices 4. There must be 20 alternating layers of copper base Advantages of 20-layer PCB 1. High assembly density, small size and light weight, meeting the needs of miniaturization of electronic equipment. 2. Due to the high assembly density, wiring between various components (including components) is reduced, installation is simple, and reliability is high. 3. Due to the repeatability and consistency of graphics, wiring and assembly errors are reduced, saving equipment maintenance, debugging and inspection time. 4. It can increase the number of wiring layers, thereby increasing design flexibility. 5. It can form a circuit with a certain impedance and form a high-speed transmission circuit. 6. Circuit and magnetic shielding layers can be set, and metal core heat dissipation layers can also be set up to meet special functional requirements such as shielding and heat dissipation. Due to its flexible design, stable and reliable electrical performance and superior economic performance, 20-layer PCB has been widely used in the production and manufacturing of electronic products. With the continuous development of electronic technology and the increasing requirements for electronic equipment in industries such as computers, healthcare, and aerospace, circuit boards are moving towards reduced volume, reduced mass, and increased density. Due to the limitations of available space, it has been impossible to further increase the assembly density of single- and double-layer printed boards. Therefore, multilayer circuit boards with more layers and higher assembly density must be considered.