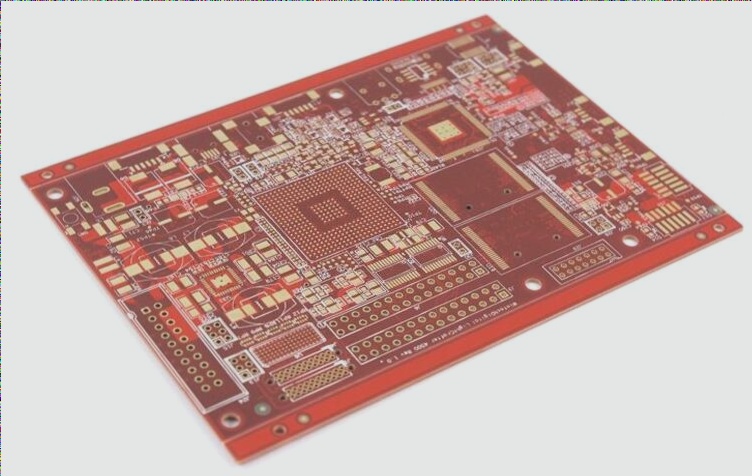

SMT Placement Machine Processing: A Comprehensive Overview

SMT placement machines play a crucial role in the electronics industry, particularly in PCB manufacturing. These machines follow a series of precise processes to ensure the accurate placement of components on circuit boards. Let’s explore the key steps involved in SMT placement machine processing:

1. Screen Printing:

The initial step in the SMT production line is screen printing. This process involves applying solder paste or adhesive to PCB pads, preparing them for component soldering.

2. Dispensing:

Following screen printing, the dispensing machine applies glue to specific locations on the PCB to secure components in place.

3. Placement:

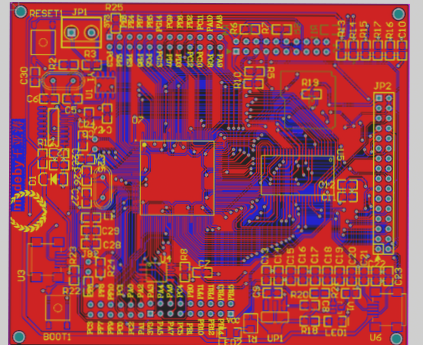

The placement machine accurately positions surface mount components on designated spots on the PCB.

4. Curing:

The curing oven heats and melts the patch adhesive, ensuring a strong bond between components and the PCB.

5. Reflow Soldering:

The reflow soldering furnace melts solder paste, creating a solid connection between components and the PCB.

6. Inspection:

Various inspection equipment, including magnifying glasses, microscopes, and automated inspection systems, are used to detect defects such as soldering errors and missing solder.

7. Repair:

Faulty PCBs undergo repair using soldering irons or rework stations positioned along the production line.

8. Cleaning:

Residues like flux are removed from assembled PCBs using cleaning machines, ensuring the final product’s quality.

While specific equipment and processes may vary among manufacturers, these essential steps form the foundation of SMT placement machine processing. Embracing these practices ensures efficient and reliable PCB assembly in the electronics industry.