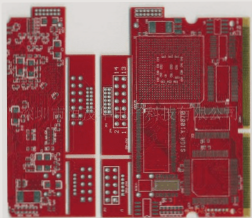

PCBs, or printed circuit boards, are essential components in the design of any product. These boards connect several parts via various means, including wires, which help create a circuit.

This board is required and can be an essential part, even if this contains all the legs of the whole circuit and we can’t lift it to the walls.

Engineering is a challenging field. If you hope to succeed, it is paramount to have the very best equipment possible. An electronic circuit board is one of the best pieces of equipment that you can use in designing electrical circuits (and even mechanical and optical ones when necessary).

You do not want to use anything other than a printed circuit board. Anything less will decrease your chances of getting the results you wish, leading to bad connections that could cause tons of problems later on. But which ones are going to be the best for your needs?

What is the PCBA?

The PCBA abbreviates “Printed Circuit Board Assembly,” and the Chinese name is “PCB assembly.

The PCBA (printed circuit board assembly) is a printed circuit board that has been inserted with electronic components and electrically connected to the elements. This is the final stage of the printed circuit board manufacturing process.

PCBAs are found in manufacturing virtually all electronic products, including computers, telephones, television sets, and other household appliances. PCBAs are also found in medicine, aerospace, and military applications.

PCB assembly service has become increasingly complex as more electronic components are used in a smaller space. These changes require manufacturers to produce more accurate and reliable PCBAs.

What Is The Main Process Of PCB Assembly?

The primary process of PCB assembly includes:

- Screen printing solder paste on printed circuit boards (circuit boards) to fix electronic components;

- The placement machine places parts on the PCB according to the component location file (BOM) provided by customers;

- The reflow oven or wave soldering machine solders electronic components to the PCB;

- The electronic components are manually packaged with parts or automatically packaged with features according to customer requirements;

- After testing and inspection, the finished products are completed.

Top 6 Applications of PCBs

Printed circuit boards, otherwise known as PCBs, have a wide range of applications in the medical industry. The main reason for this is that manufacturers can create tiny printed circuit boards used in electronic medical devices and equipment.

Application in Medical Equipment

Medical equipment is the primary application of PCBs designed to use in medical devices. They have a lot of features, such as press-fit connectors and small component mounting, which can allow them to be used in modern medical equipment.

With the prevalence of PCB fabrication technologies, these boards are easy to produce with high quality. Moreover, the medical field utilizes PCBs in CT scanners, Magnetic Resonance Imaging (MRI), and other imaging devices.

The printed circuit boards used here have multiple layers, as there is a need for higher density circuitry. In addition to this, these circuit boards also need to be very durable and robust.

- Medical Imaging System:

PCBs are commonly used in medical imaging systems such as CT, CAT, ultrasonic scanners, and computers that assemble and analyze the data.

- Monitors:

Electronic components are used in heart rate, blood pressure, blood glucose monitors, and other devices to produce reliable data.

- Infusion Pumps:

Supply exact fluid volumes to a patient, such as insulin and patient-controlled analgesia pumps. These products rely on PCBs to perform consistently and precisely.

- Internal Devices:

The operation of pacemakers and other internal devices necessitates the use of small PCBs.

Application in LEDs

LEDs (Light Emitting Diodes) are widely applied in our life because they require less energy consumption and have a longer lifespan than traditional incandescent bulbs. Generating light from electricity is called electroluminescence, which is different from an incandescent bulb.

The principle of electroluminescence is that when electrons come across a free hole, they eliminate energy in the form of photons (light). They have tiny circuit boards that control their brightness and other parameters.

LED PCBs can be found in the following places:

- Residential Lighting:

LED lighting, including intelligent bulbs, saves energy and money for homeowners.

- Storefront Lighting:

LEDs can be used for signage as well as illumination in storefronts.

- Automotive Displays:

LED PCBs may be used in dashboard indicators, headlights, brake lights, and other automotive displays.

- Computers Displays:

LED PCBs power many indicators and displays on laptop and desktop computers.

- Medical Lighting:

Because LEDs produce intense light while emitting little heat, they are perfect for medical applications, particularly in surgery and emergency treatment.

Application in Industrial Equipment

PCBs are used in a wide range of industrial electronic applications. They are used in various manufacturing, power, and measurement applications. Their high performance and resistance to the harsh conditions of industrial applications make them the perfect choice for electronics in many industries.

- Manufacturing Equipment:

PCBs are used in industrial manufacturing equipment such as 3D printers, laser cutters, CNC machines, etc. The electronic components on these boards help the machines operate efficiently and maintain their accuracy over time.

- Power Equipment:

Power supply and distribution boards are used in industrial settings to ensure that all machinery runs at total capacity without power fluctuations or failures.

These boards use a variety of components to regulate the power flow, including copper traces, resistors, capacitors, and inductors.

- Measuring Equipment:

Industrial measuring devices use PCBs to record and track data on materials or products manufactured within the factory. For example, PCBs are used in humidity sensors that measure moisture levels in the air during production and log this information.

Application in Automotive Components

Semiconductors have become an integral part of modern vehicles and are expected to play a pivotal role in the future of automotive electronics. As autonomous, electric, and connected cars enter the market, semiconductor manufacturers will be positioned to capture significant growth opportunities.

- Entertainment and Navigation Systems:

In modern cars, owners have expected a high level of entertainment, information, and communication systems.

These systems typically involve a central processing unit (CPU) that controls the navigation system. It also contains other functions such as music or media storage, telematics and telephone functions, external power source charging (for mobile phones, etc.), digital radio, DVD players, and multimedia consoles. This advanced CPU is often a PCB itself.

- Control Systems:

Electronic control units (ECUs) are embedded control computers used in vehicles to control electronic devices or subsystems such as an engine or transmission. Typically, ECUs are located in a vehicle’s cabin near the driver’s seat.

The ECU monitors sensors through the CAN bus network to determine whether the engine requires more fuel, ignition timing adjustment, or other changes to improve performance and efficiency.

- Sensors:

PCBs are also used in many sensors throughout a vehicle that constantly provides data on everything from temperature to humidity to acceleration.

Some examples include pressure sensors for airbags, headlights, and bumpers; proximity sensors for doors; tire-pressure monitors; speedometers; oil pressure sensors; thermal sensors for cooling; and GPS antennas for navigation.

Application in Consumer Electronics

As consumer interest in electronics increases, the demand for printed circuit boards (PCBs) increases. PCBs are used in a wide variety of consumer electronic applications. Some standard consumer devices that use PCBs include:

- Communications Devices:

PCBs are used in various consumer electronics products like mobile phones, PDAs, laptops, tablets, and other wireless communication devices. These PCBs can be simple with a few components or complex with several layers of component interconnections.

Though the PCBs are getting smaller and slimmer with each new product version, the complexity is increasing proportionately. Mobile phone PCBs have evolved from 2 to 3 layers to multilayer HDI boards.

- Computers:

Computers also use PCBs which have become more compact as desktop computers became laptop computers and then netbooks and tablet PCs. The PCB design has also become more complex due to the growth in computer systems’ processing power and capabilities.

- Home Appliances:

PCB assemblies are now an integral part of home appliances like washing machines and refrigerators.

These devices use PCBs ranging from simple single-layer boards to complex multilayer boards that contain several layers of high-density interconnections between components.

Application in Aerospace Components

The use of PCBs in aerospace is close to universal. From communications equipment to control equipment to power supplies, the PCB has made its way into every part of modern aerospace vehicles.

The reason for this wide adoption is simple – PCBs are smaller and lighter than other circuit solutions, and they are also cheaper, more reliable, and easier to manufacture.

These benefits allow aircraft manufacturers to create smaller, lighter components that use less energy than any other option. This, in turn, means the aircraft itself can be smaller and lighter and more fuel-efficient – a crucial consideration in today’s competitive airline industry.

Here are some examples of how printed circuit boards are used in aerospace:

- Power Supplies:

Power supply units are used extensively in aerospace equipment to provide voltage signals for other components. These power supply units can be used in different areas of an aircraft and are designed for various purposes.

For example, a power supply system used in the cockpit of an aircraft would be designed specifically for this environment, whereas a power supply unit used to fuel the engine might have different requirements.

- Monitoring Equipment:

Monitoring equipment forms an essential part of any modern aircraft. It is used for checking the performance and status of the vehicle and other functions such as determining the location of the craft.

Printed circuit boards are commonly used in monitoring equipment to ensure the devices are lightweight and easy to install within the limited space available on aircraft.

- Communication Equipment:

Communication between air traffic control and pilots is conducted using radio communication equipment on the ground and aircraft themselves.

PCBs are widely used in these devices due to their suitability for high-frequency applications, which is a requirement of radio communications technology.

Bottom Line:

Many old-school manufacturing processes have been primarily automated in recent years, making these processes more efficient and cost-effective. For this reason, the application of PCBA (Printed Circuit Board Assembly) has grown among businesses looking to source their products cost-effectively.

Today, PCBA applications have become highly popular as they provide several benefits that can be leveraged by businesses looking to bring down production costs while improving product performance.