Understanding Radio Frequency (RF) and RF PCBs

Radio frequency, often abbreviated as RF, is a type of high-frequency alternating current electromagnetic waves. It falls under the category of high-frequency current, with alternating current that changes more than 10000 times per second. In electronics, RF refers to modulated radio waves generated by circuits at a specific frequency.

RF PCB in Electronics

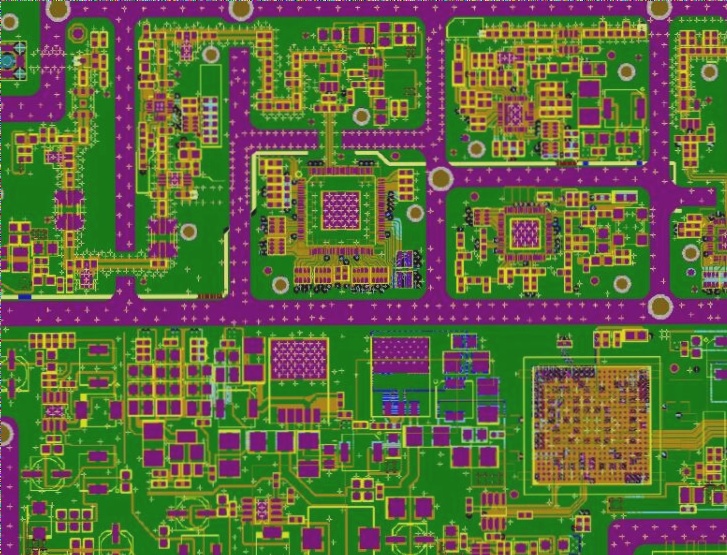

RF PCB, which stands for Radio Frequency Printed Circuit Board, is a crucial part of electronic devices that deal with high frequencies. It encompasses the circuit running from the antenna to the baseband signals. Engineers designing RF PCBs must consider factors like signal transmission, impedance control, signal integrity, and electromagnetic compatibility.

Key Considerations for RF PCB Design

- Optimizing PCB materials with high dielectric constant and low loss for efficient signal transmission.

- Strategically wiring to minimize signal reflection and loss while addressing signal integrity and EMC concerns.

- Designing ground planes to reduce noise and interference.

- Selecting appropriate substrates like FR4, TACONIC, and ROGERS for high performance.

Standards for RF PCB

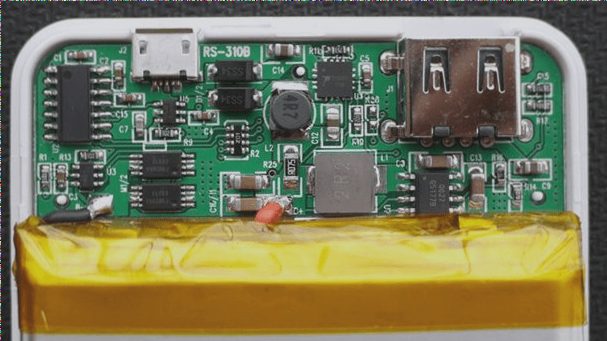

- Using standard RF4 materials for low-power RF circuit boards.

- Tightly arranging components for the shortest connections.

- Separating RF and analog parts from the digital part in mixed-signal PCBs.

Impedance Control and Characteristics

Impedance control is crucial in RF PCBs to ensure proper signal transmission. Designers must understand the characteristic impedance of the printed wiring related to PCB materials and parameters.

Basic Characteristics of RF PCBs

RF PCBs play a vital role in wireless transmitters and receivers, handling fundamental and radio frequencies. The selection of materials impacts signal processing, conversion, and transmission in RF circuits.