2. Characteristics of PCBA packaging materials.

1. PCBA contracting for labor and materials effectively saves customers time and costs while transferring the entire manufacturing process control to professional and experienced suppliers. This approach minimizes the need for bargaining, reduces purchasing time, eliminates inventory costs, and streamlines material inspections for electronic components like ICs, resistors, capacitors, and diodes. By shifting these responsibilities, companies can effectively mitigate risks, including personnel expenses. While the upfront quotations for labor and materials may appear high, they can ultimately reduce overall enterprise costs by offsetting hidden expenses, allowing companies to focus on their core competencies such as design, R&D, marketing, and after-sales service.

2. Next, let’s consider the potential derivative risks associated with PCBA labor and materials. Supplier audits play a crucial role in the success of contract labor and materials services, significantly influencing whether costs and product turnover meet expected goals. The market does have entities that prioritize excess profits at the expense of customer quality and ethical sourcing; however, this practice is not sustainable in the long run. Shenzhen Zhengjiaxiang Electronic Technology Co., Ltd. firmly believes that companies aspiring to thrive in the industry must adhere to a higher standard. Thus, effective supplier auditing hinges not on mere words, but on actions—addressing customer issues takes precedence over factors like equipment, factory size, and certifications.

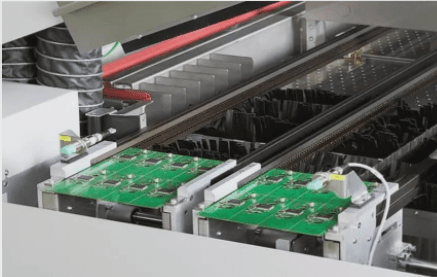

3. Finally, let’s explore the PCBA electronics manufacturing process involving contract labor and materials. A crucial evaluation during product design is Design For Manufacturability (DFM), which is vital for quality control in the manufacturing process, helping to minimize disputes with suppliers over problem origins. Once the customer finalizes the product design, they submit the PCB files, BOM list, and other engineering documents to the supplier. Typically, a dedicated technician from the supplier reviews and confirms the details of stencil printing, patch processes, and plug-in processes. Following this, the customer usually prepays a portion of the labor and materials (ranging from 30% to 80%, generally around 70% depending on product profitability). Upon receiving payment, the supplier procures components and prepares materials according to the production plan, leading to acceptance and payment of the remaining balance by the customer.

—

Let me know if you need any more adjustments!