What does a PCB stencil do? – WellCircuits

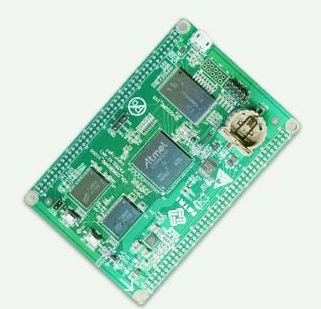

Understanding PCB Stencil:

A PCB stencil is a thin sheet made out of stainless steel. It contains laser cut openings on its surface, which helps in the proper mounting and placement of the PCB board.

The PCB stencil is utilized to store bind glue on assigned spots on an uncovered PCB board so that parts can be appropriately set and be entirely adjusted on the board. The fundamental feature and purpose of a PCB stencil are to precisely store the perfect measure of solder paste on SMT cushions for the weld joint between the cushion and the part to be appropriately structured concerning the electrical connection and mechanical strength. Utilizing a PCB Stencil to put solder paste makes the PCB Assembly process quicker and more efficient.

Types of PCB Stencils

- Hybrid PCB Stencils

- Prototype or Photo PCB Stencils

- Frameless/ Reusable PCB Stencils

- Framed / Framework PCB Stencils

- Chemical-etch PCB Stencils

- Laser-cut PCB Stencils

In this article, let us dig deeper and discuss each of these types in detail.

Laser-cut Stencils:

In the case of Laser cut stencils, the openings or apertures are cut out with laser beams’ assistance. These laser beams offer great precision and make sure that the openings and apertures are accurate.

Chemical-etch Stencils:

The openings on the PCB Stencil are carved into metal utilizing destructive that acts as a PCB stencil printer. Such Stencil offers high assembling speed requiring little to no effort yet doesn’t ensure the earth against destructive synthetic compounds.

Framed / Framework PCB Stencils:

These circuit board stencils accompany a casing around the Stencil. A work outskirt is utilized for the casing, which keeps the stencil sheet tight for the ideal exactness. Confined PCB Stencils offer predictable repeatability, remarkable print quality, and are utilized for high volume PCB creation.

Frameless/ Reusable PCB Stencils:

Frameless or Reusable PCB stencil does not have a fixed casing around them. They can be balanced into various edges and can be expelled according to the requirements. They are more affordable than the other types of PCB stencils that come with outlines. Frameless or Reusable PCB stencils can be utilized with hand fastening forms and diminish the prerequisites for additional storage space.

Prototype or Photo Stencils:

These stencils depend on a particular structure that is uniquely crafted to suit the Prototype or photo stencils arranged to utilize CAD or Gerber record. These are utilized for manual printing and to carry out activities according to the needs of the individual.

Hybrid PCB Stencils:

Hybrid PCB stencil is a blend of the laser-cut Stencil and the chemically etched Stencil. Therefore, it carries the features of both types of PCB stencils and can be utilized in specific situations.

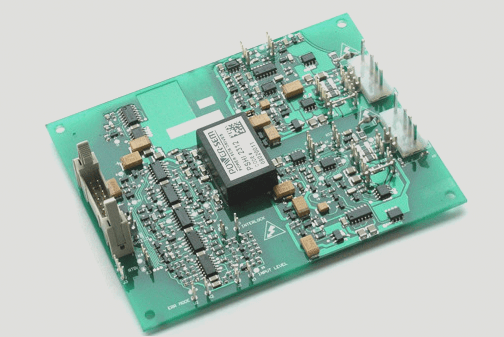

How are PCB Stencils Manufactured?

PCB Stencils are produced by making openings or apertures through laser beams on a hardened steel foil-based sheet at the positions where Surface Mount segments are to be set on the circuit board. The Stencil is then positioned on the head of the PCB circuit board and adjusted properly utilizing certain focuses called fiducial imprints.

After arrangement, the solder paste is applied with a metal tool cutting edge. According to the size and position, the solder paste gets set on the PCB circuit board where the surface mount parts should be placed according to their position. So, when the PCB stencil is evacuated, parts can be set on the board in their determined position properly.

Important points to keep in mind while ordering PCB Stencils:

Here are a few points to adhere to before ordering PCB stencils.

The thickness of the stainless-steel sheet:

An appropriate thickness of the stencil sheet guarantees that the application of the solder paste would be in the proper quantity or even measured through the opening

The thickness of the sheet and opening size are the significant elements that influence the measure of solder paste to be stored on the board since the deposit of excess solder paste can cause the welds to cross over.

Contrary to this condition, the release of lesser solder paste than required can likewise lead to feeble bind joints, which can further influence the utility and life of the PCB board that is obtained after the complete procedure.

The aperture size of the opening created:

To keep away from mistakes such as bridging and formation of solder beads, the opening of the PCB stencil is structured in a size that is somewhat smaller than the size of the PCB cushion.

After the application of the solder paste, with Stencil being expelled from the board, there is the likelihood that the solder paste may get displaced onto the PCB board. It can even take place on sticks on to the gap in the dividers of the Stencil. The zone of PCB cushion must always be more than 66% of the size of the region of aperture wall of the Stencil to stay away from this kind of an issue.

Stencil Alignment:

In order to get an ideal print of solder paste on the PCB cushions, enrolment marks called ‘fiducial imprints’ are added to both PCB and the PCB stencil. These fiducial imprints guarantee that the arrangement between the PCB and Stencil is perfect.

The gap to the PCB cushion:

Stainless steel is the material that is most commonly used for making PCB stencils. It is also undoubtedly the best material to produce a PCB stencil.

Stencil Material:

The stencil material likewise influences its capacity to convey the solder paste from the opening or the gap to the PCB cushion. Stainless steel is the material that is most commonly used for making PCB stencils. It is also undoubtedly the best material to produce a PCB stencil.

Conclusion:

PCB stencils are an important tool to guarantee precision at every step in the process of making PCB boards. They are extremely helpful in making sure that there is no deposition of excess solder paste or any other default, further hampering the smooth working of the PCB board.