Understanding Halogen-Free PCBs in Modern Electronics

Halogen-free PCBs have become a significant topic in the realm of Printed Circuit Boards (PCBs) due to their unique composition and environmental benefits. These PCBs exclude halogen elements like chlorine, bromine, fluorine, iodine, and astatine, which are known to be harmful to living organisms.

Manufacturers are increasingly opting for Halogen-free PCBs to comply with regulations like RoHS (Restriction of Hazardous Substances) and promote safer practices in electronic product manufacturing.

The Importance of Halogen-Free PCBs

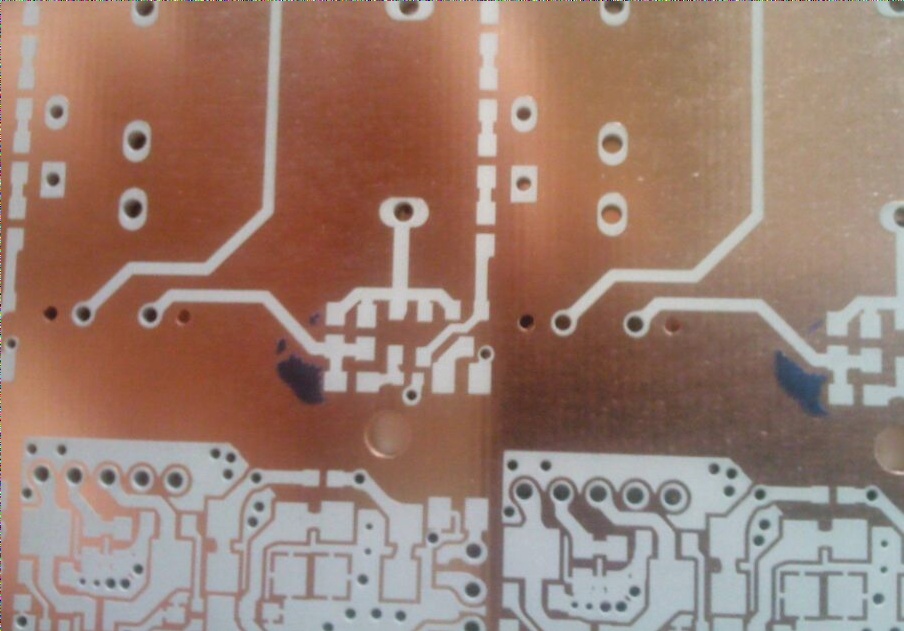

- Environmental Safety: Halogen elements in traditional PCBs emit toxic gases when burned, posing risks to human health and the environment.

- Regulatory Compliance: Regulations like RoHS restrict the use of halogenated flame retardants in electronic products, driving the adoption of Halogen-free PCBs.

- Enhanced Performance: Halogen-free PCBs exhibit improved insulation resistance, breakdown voltage, and reduced coefficient of thermal expansion, enhancing overall reliability.

Transition to Phosphorus-Nitrogen Compounds

In modern PCB production, phosphorus-nitrogen compounds are preferred over halogens for their flame retardancy and environmental sustainability. These compounds decompose during resin burning, releasing non-combustible gases that suppress fire propagation.

Replacing halogens with phosphorus and nitrogen not only enhances flame retardancy but also improves the mechanical and thermal properties of PCBs, making them more reliable and efficient.

Looking Ahead

As the electronics industry continues to prioritize sustainability and safety, the shift towards Halogen-free PCBs is set to revolutionize electronic product manufacturing. These PCBs offer a safer and more environmentally friendly alternative without compromising on performance.

For further information on Halogen-free PCBs and their benefits, keep exploring below: