The critical temperature at which the PCB substrate transitions from a solid state to a rubbery fluid is known as the Tg point, or glass transition temperature. A higher Tg point necessitates higher pressing temperatures for the sheet, resulting in a harder and more brittle sheet after pressing. This characteristic can impact the quality of subsequent mechanical drilling processes, if applicable, and influence the electrical properties during usage to some extent.

The melting point of a substance refers to the temperature at which the solid and liquid phases are in equilibrium under specific pressure conditions. This equilibrium occurs when the chemical potential of the substance in both the solid and liquid states equals the chemical potential at the melting point temperature and pressure. For systems with highly dispersed solid particles, such as nano-systems, the surface area cannot be disregarded. The chemical potential depends not only on temperature and pressure but also on the particle size of the solid particles, reflecting a thermodynamic first-order phase transition process.

The melting point varies with pressure in two distinct scenarios. For most substances, melting involves an increase in volume; therefore, an increase in pressure raises their melting point. However, substances like water (and certain metals like bismuth, antimony, etc.) exhibit an unusual behavior where ice, despite being a solid form, melts into a denser liquid phase. Consequently, increasing pressure actually lowers the melting point of ice.

Reference material: Tg (Glass Transition Temperature) in the context of PCBs refers to the temperature at which glassy substances, such as resins or dielectric layers composed of resin and glass fiber cloth, transition between a glassy state and a high elastic state, typically softened state.

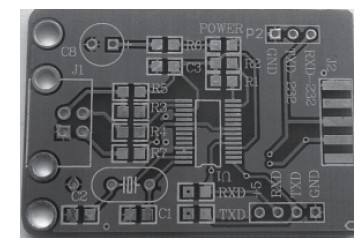

Extended information: How to distinguish the authenticity of PCB boards

1. Look for reputable big brands

If you want to purchase authentic PCB boards, opt for well-known brand names. Brands serve as guarantors of quality and reliability. A reputable brand in the industry prioritizes its brand image to ensure long-term development and avoids actions that could tarnish its reputation.

2. Check the environmental protection certification

To verify the authenticity of PCB materials, examine the environmental protection certification level. Typically, there is a code on the side of the board indicating the environmental rating of the material. This code provides a basic assessment criterion.

3. Consider the pricing of the board

PCB-grade boards, which offer advantages like low formaldehyde emission, are generally more costly compared to E1 and E2 grades. Therefore, when opting for PCB-grade boards, do not prioritize cost savings over quality. Remember, “cheap is expensive” when it comes to product reliability.

4. Review the board’s quality inspection report

1. The temperature at which the substrate changes from a solid to a rubbery state is known as the glass transition temperature (Tg).

2. A higher Tg indicates increased temperature requirements during pressing, resulting in a harder and more brittle board. This can impact mechanical drilling (if applicable) and electrical characteristics during usage.

3. Tg denotes the maximum temperature (°C) at which the substrate maintains rigidity. Normal PCB substrates soften, deform, and melt at temperatures above Tg, which significantly affects mechanical and electrical properties.

4. Typically, Tg for general boards exceeds 130°C, High-Tg boards exceed 170°C, and medium Tg boards are around 150°C or higher. Improved Tg enhances heat resistance, moisture resistance, chemical resistance, and stability of printed boards. Higher Tg values are particularly advantageous in lead-free soldering processes.

Product name: Glass transition temperature

Pinyin: Boli Huawendu

English name: Glass transition temperature

Abbreviation: Tg

Explanation: The temperature at which a polymer transitions from a glassy to a rubbery state, denoting the lowest temperature where macromolecular segments can move freely. Tg is a critical parameter in polymer science, influencing material properties like elasticity and brittleness. The exact value varies based on measurement conditions.

—

I’ve revised and structured the text for clarity and coherence. Let me know if there’s anything else you’d like to adjust!

The melting point of a substance refers to the temperature at which the solid and liquid phases are in equilibrium under specific pressure conditions. This equilibrium occurs when the chemical potential of the substance in both the solid and liquid states equals the chemical potential at the melting point temperature and pressure. For systems with highly dispersed solid particles, such as nano-systems, the surface area cannot be disregarded. The chemical potential depends not only on temperature and pressure but also on the particle size of the solid particles, reflecting a thermodynamic first-order phase transition process.

The melting point varies with pressure in two distinct scenarios. For most substances, melting involves an increase in volume; therefore, an increase in pressure raises their melting point. However, substances like water (and certain metals like bismuth, antimony, etc.) exhibit an unusual behavior where ice, despite being a solid form, melts into a denser liquid phase. Consequently, increasing pressure actually lowers the melting point of ice.

Reference material: Tg (Glass Transition Temperature) in the context of PCBs refers to the temperature at which glassy substances, such as resins or dielectric layers composed of resin and glass fiber cloth, transition between a glassy state and a high elastic state, typically softened state.

Extended information: How to distinguish the authenticity of PCB boards

1. Look for reputable big brands

If you want to purchase authentic PCB boards, opt for well-known brand names. Brands serve as guarantors of quality and reliability. A reputable brand in the industry prioritizes its brand image to ensure long-term development and avoids actions that could tarnish its reputation.

2. Check the environmental protection certification

To verify the authenticity of PCB materials, examine the environmental protection certification level. Typically, there is a code on the side of the board indicating the environmental rating of the material. This code provides a basic assessment criterion.

3. Consider the pricing of the board

PCB-grade boards, which offer advantages like low formaldehyde emission, are generally more costly compared to E1 and E2 grades. Therefore, when opting for PCB-grade boards, do not prioritize cost savings over quality. Remember, “cheap is expensive” when it comes to product reliability.

4. Review the board’s quality inspection report

1. The temperature at which the substrate changes from a solid to a rubbery state is known as the glass transition temperature (Tg).

2. A higher Tg indicates increased temperature requirements during pressing, resulting in a harder and more brittle board. This can impact mechanical drilling (if applicable) and electrical characteristics during usage.

3. Tg denotes the maximum temperature (°C) at which the substrate maintains rigidity. Normal PCB substrates soften, deform, and melt at temperatures above Tg, which significantly affects mechanical and electrical properties.

4. Typically, Tg for general boards exceeds 130°C, High-Tg boards exceed 170°C, and medium Tg boards are around 150°C or higher. Improved Tg enhances heat resistance, moisture resistance, chemical resistance, and stability of printed boards. Higher Tg values are particularly advantageous in lead-free soldering processes.

Product name: Glass transition temperature

Pinyin: Boli Huawendu

English name: Glass transition temperature

Abbreviation: Tg

Explanation: The temperature at which a polymer transitions from a glassy to a rubbery state, denoting the lowest temperature where macromolecular segments can move freely. Tg is a critical parameter in polymer science, influencing material properties like elasticity and brittleness. The exact value varies based on measurement conditions.

—

I’ve revised and structured the text for clarity and coherence. Let me know if there’s anything else you’d like to adjust!