The Significance of Cavity PCBs in Modern Electronics

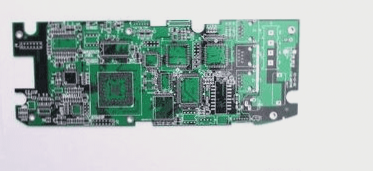

With the continuous miniaturization of printed circuit boards (PCBs), the space available for wiring and components is becoming more limited. In such scenarios, cavity PCBs offer a practical solution.

Understanding Cavity PCBs

A cavity in a PCB refers to a hole that extends from the outer copper layer to the inner copper layer without penetrating the board entirely. By placing components within these cavities, the height of the components can be reduced, leading to a more compact circuit board. This compact design allows for enhanced functionality and layout optimization within a confined space. Moreover, cavities create additional space and increase the distance between components, thereby reducing interference and improving the reliability and performance of the circuit. Furthermore, cavities can serve to expand the surface area for heat dissipation, which is especially crucial for small yet high-power circuit boards. By incorporating heat dissipation structures within the concave cavities, heat can be efficiently dispersed, ensuring the stable operation of components even under heavy loads.

Types of Cavity PCBs

The latest IPC standard, IPC-6012F, outlines three types of recessed cavities and their corresponding specifications:

- Type 1: No copper plating or metallization inside the cavity.

- Type 2: Copper plating on the top/bottom or walls (but not both) of the cavity, the most common type.

- Type 3: Both the cavity walls and floor area are copper-plated.

Cavities with internal copper, such as traces and pads, are categorized as Type 2, while cavities with partially copper-plated walls are classified as Type 3.

In certain instances, cavities can be completely filled with copper through a process known as copper coining. This technique is often employed to create a large heat sink within the PCB. Placing a copper coin beneath a component significantly enhances heat transfer within the board. When the copper coin is connected to an electrical plane or positioned near a substantial electrical plane, it aids in dissipating heat away from the heat source. This method can also be utilized to bond components to the case, where the coin and case together form a substantial heat sink.

Advantages and Applications

The advantages of cavity PCBs include:

- Reduction in product size and weight

- Increased assembly density

- Enhanced overall product performance

- Meeting high-speed and high-information requirements of communication devices

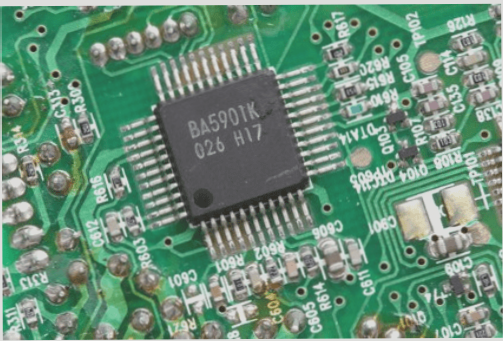

- Improved stability of surface-mounted components

- Expansion of the heat dissipation area

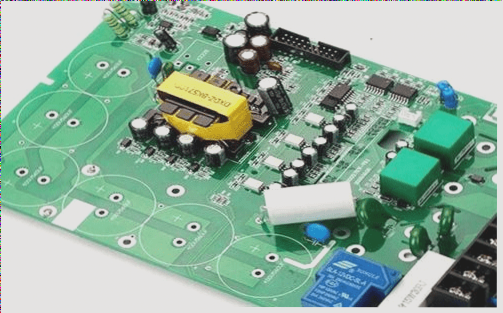

Cavity PCBs find applications in various fields such as RF and microwave applications, telecommunications, central hybrid automotive systems, high-current circuits, power amplifiers, DC power supplies, motor control modules, electric vehicle powertrains, and high-speed computing. In high-frequency antenna circuit boards, the removal of unnecessary layers can minimize signal loss, making cavity PCBs ideal for wireless communication applications like smartphones and related infrastructure. Additionally, these PCBs are effective in managing waste heat generated by power components through targeted material removal.

If you have any inquiries about PCBs and PCBA, please don’t hesitate to reach out to us at info@wellcircuits.com