FPC Flexible Circuit Boards: Advantages and Applications

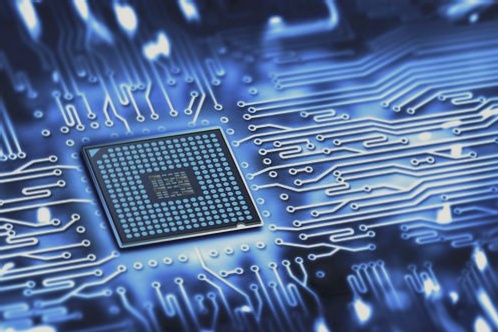

- FPC, or Flexible Printed Circuit, is a type of circuit board known for its high wiring density, lightweight, and thin profile.

- Commonly used in devices like mobile phones, laptops, PDAs, digital cameras, and more.

- Characterized by high wiring density, low weight, and thinness.

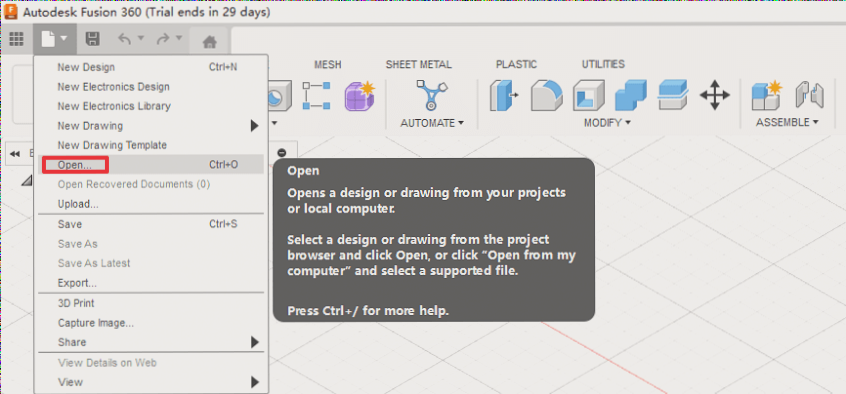

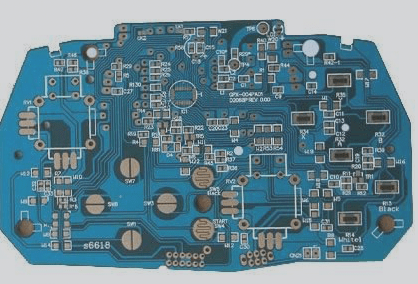

FPC Double-layer PCB Board

FPC flexible circuit boards are highly reliable and efficient, made from polyimide or polyester film as the substrate material. They are classified into adhesive-based and non-adhesive flexible boards.

The price of glueless flexible boards is higher but offers superior flexibility and bonding strength compared to glued boards.

FPC Flexible Board Structure

Flexible boards come in single-layer, double-layer, and multi-layer forms. They are used in applications requiring bending and have specific design and process requirements.

FPC Application Field

Applications include MP3 and MP4 players, portable CD players, digital cameras, mobile phones, medical, automotive, aerospace, and military sectors.

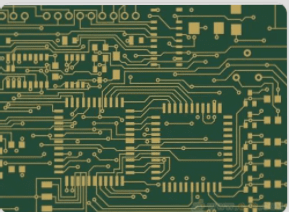

Flexible copper clad laminates (FPC) made from epoxy resin are becoming more popular for their unique functions.

However, the development of these laminates started later in some countries, including our own, and there is room for growth in this area.

The Evolution of Epoxy Flexible Printed Circuit Boards

Epoxy flexible printed circuit boards have come a long way since their inception over 30 years ago. The journey from the 1970s to the late 1980s saw significant advancements in the industry, particularly with the introduction of new polyimide film materials. These materials paved the way for the development of non-adhesive FPCs, also known as “two-layer FPCs.”

In the 1990s, a game-changer arrived in the form of photosensitive cover films designed for high-density circuits. This innovation revolutionized FPC design and opened up new possibilities for applications in various industries.

With the emergence of new application areas, there was a shift towards exploring different product forms. This led to the adoption of a wider range of substrates for technologies like Tape Automated Bonding (TAB) and Chip-On-Board (COB).

The latter half of the 1990s witnessed the rise of high-density FPCs on a large scale. Circuit patterns became more intricate and sophisticated, meeting the demands of a rapidly expanding market for high-density FPCs.