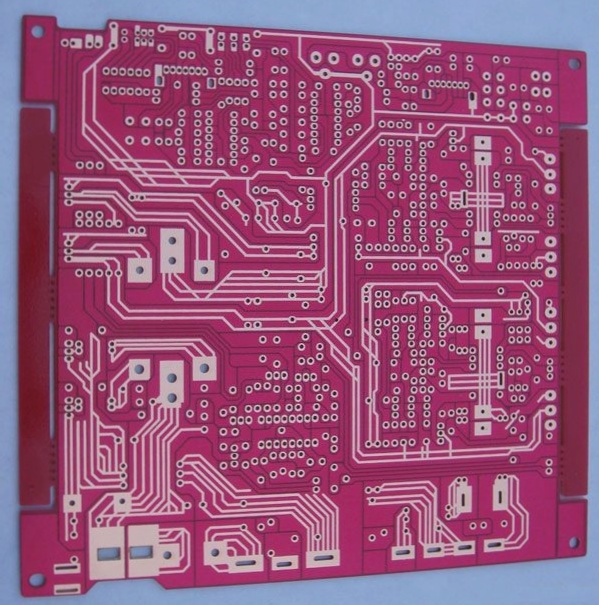

Metal core PCBs, also known as MCPCBs, integrate a thermally conductive metal core—such as aluminum, copper, or stainless steel—in place of the traditional FR4. This metal core functions as an efficient heat sink, effectively conducting and dissipating the heat generated by components on the PCB.

Advantages

Efficient Heat Transfer: One of the key benefits of MCPCBs is their exceptional heat transfer performance. They can dissipate heat approximately 8 to 9 times faster than FR4 PCBs. To enhance thermal management, MCPCBs feature a thin dielectric layer, typically ranging from 0.003 to 0.006 inches. This thin layer shortens the heat path, allowing heat to travel directly from the heat source to the metal core. Additionally, the metal core serves as an integrated heat sink, further improving the efficiency of heat dissipation into the surrounding environment.

High Mechanical Strength: Metal Core PCBs offer superior mechanical strength compared to traditional FR4 PCBs. The inclusion of the metal core enhances rigidity and stability, making the PCB more resistant to bending, warping, and mechanical stress. This makes MCPCBs especially advantageous in industries like automotive, aerospace, and industrial automation, where PCBs must endure demanding and harsh operating environments.

Improved Thermal Expansion Compatibility: The coefficient of thermal expansion (CTE) of Metal Core PCBs closely aligns with that of semiconductor components, such as LEDs and power devices. This compatibility helps minimize the risk of thermal stress-related failures caused by mismatched expansion rates between the PCB and its components. A close match in CTE ensures long-term reliability and durability for electronic assemblies.

Design Flexibility: Metal Core PCBs offer considerable design flexibility, allowing for various mounting options, including direct soldering of components and press-fit connectors. This flexibility makes it easier to create customized designs tailored to specific application needs.

Applications

Metal core PCBs are particularly well-suited for applications where efficient heat dissipation is critical, such as in LED lighting, power electronics, automotive systems, renewable energy technologies, and computer hardware. In LED lighting applications, for example, LEDs are highly efficient at converting electrical energy into light but produce heat as a byproduct. If not properly managed, this heat can affect both the performance and lifespan of LEDs. Metal core PCBs are highly effective at absorbing and dispersing this heat, ensuring reliable LED operation and maximizing their efficiency.

If you have any questions about PCBs or PCBA, please contact us at info@wellcircuits.com.