PCBs, or Printed Circuit Boards, are the backbone of modern electronics. They provide a platform for mounting electronic components such as resistors, capacitors, and microchips. PCBs are essential in devices ranging from smartphones to medical equipment and household appliances.

Understanding the Basics of PCB

A PCB is typically made from non-conductive materials like fiberglass or epoxy, and it features conductive pathways etched or printed onto its surface. These pathways, also known as traces, form the electrical connections between the components.

What Materials Are Used to Make PCBs?

- Fiberglass: Known for its durability and electrical insulation properties, fiberglass is the most common material used in the construction of PCBs.

- Epoxy: Epoxy resins provide structural strength and are resistant to heat, making them ideal for high-performance boards.

- Copper: Used to form the conductive traces, copper is a crucial material in PCB manufacturing.

Types of PCBs

PCBs come in various forms, including single-sided, double-sided, and multi-layer boards. Each type has specific applications depending on the complexity of the circuit design and the device it is used in.

Single-Sided PCB

As the name suggests, single-sided PCBs have components mounted on one side of the board only. These are often used in simpler devices like basic appliances.

Double-Sided PCB

These PCBs have components mounted on both sides, allowing for more complex circuit designs. Double-sided boards are typically used in applications that require a higher degree of functionality.

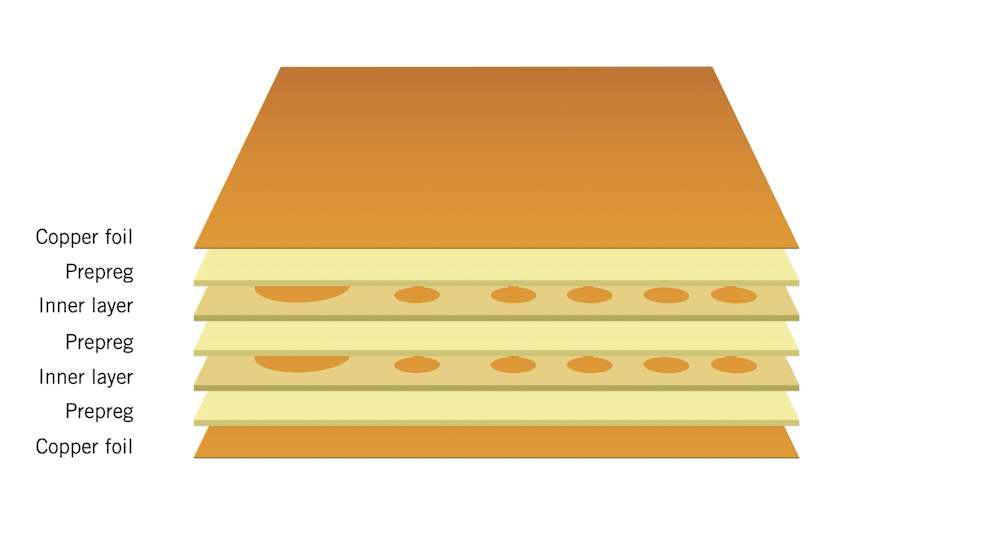

Multi-Layer PCB

Multi-layer PCBs consist of several layers of circuitry stacked together, providing more space for complex components and making them suitable for high-performance electronics like computers and medical devices.

Why Are PCBs So Important?

PCBs provide several crucial benefits to electronics:

- Compact Design: PCBs enable the miniaturization of electronic devices by allowing components to be efficiently placed on a single board.

- Reliability: PCBs are designed for long-term durability and resistance to wear and tear, ensuring the reliability of electronic devices over time.

- Cost-Effective Manufacturing: PCBs can be mass-produced at relatively low cost, making them ideal for high-volume production of consumer electronics.

PCBs: The Foundation of PCB Assemblies (PCB-As)

The production of PCB assemblies (PCB-As) relies heavily on the quality of the PCB itself. A PCB is the base component onto which electronic components like resistors, capacitors, and microchips are mounted. Without a reliable PCB, the entire assembly would fail. Therefore, it’s crucial for manufacturers to ensure that the PCB meets the required standards before proceeding with assembly.

High-Quality Standards for Demanding Customers

As technology advances, the demand for high-quality, high-performance PCBs grows. Customers with stringent requirements expect manufacturers to deliver PCBs that are reliable, durable, and meet the highest industry standards. Whether for consumer electronics, medical devices, or automotive applications, a dependable PCB is essential for the success of the final product.

If you’re looking to design or manufacture PCBs, it’s important to work with experienced engineers and designers to ensure the board meets the necessary specifications. Download our design guidelines to get started on creating high-performance, cost-effective PCBs for your next project.

How Are PCBs Manufactured?

PCB manufacturing involves several key steps:

- Design: Engineers design the PCB layout using specialized software.

- Printing: The design is printed onto the board using a process called photolithography, where the copper traces are etched onto the board.

- Assembly: Components are then mounted on the board using either hand-soldering or automated placement machines.

- Testing: The finished PCBs undergo rigorous testing to ensure they meet quality standards and function correctly.

Applications of PCBs

PCBs are used in a wide range of industries:

- Consumer Electronics: Smartphones, laptops, and televisions rely on PCBs to function.

- Automotive Industry: Modern vehicles contain numerous PCBs that control everything from infotainment systems to safety features.

- Medical Devices: PCBs are crucial in devices like pacemakers, diagnostic machines, and surgical robots.

- Industrial Equipment: From power systems to manufacturing machinery, PCBs are key components in industrial automation.

At first glance, printed circuit boards (PCBs) might seem quite similar, regardless of their quality. However, subtle differences exist that can dramatically influence the durability and overall performance of the PCB throughout its lifecycle. There is a significant gap between a basic PCB and a high-performance PCB. The key lies in precision and attention to detail.

PCBs come in various types, each tailored for specific applications, offering different levels of functionality, flexibility, and performance. These are not “one-size-fits-all” solutions; instead, each design is custom-built to serve a particular purpose—no other design can fulfill this exact role.

Depending on the industry and the intended application, the requirements for a PCB can vary greatly. Moreover, each industry follows specific standards and regulations that must be adhered to during the design and manufacturing processes.

Explore Our PCB Expertise Across Industries

We specialize in providing customized PCB solutions across a wide range of industries. Learn more about how we serve different sectors and ensure high-quality standards in all our products.

- Medical Devices & Healthcare

- Automotive Electronics

- Consumer Electronics

- Industrial Applications

- Telecommunications

Why Choose WellCircuits for Your PCB Needs?

Wellcircuits is a leading provider of high-quality PCBs, offering cutting-edge solutions for various industries. With years of expertise in PCB manufacturing, NCAB ensures precision, durability, and the latest technology in every board.

Contact WellCircuits

For custom PCB designs, fast prototyping, and reliable manufacturing, get in touch with Wellcircuits. Our team is here to assist with all your PCB needs and provide expert guidance tailored to your specific requirements.