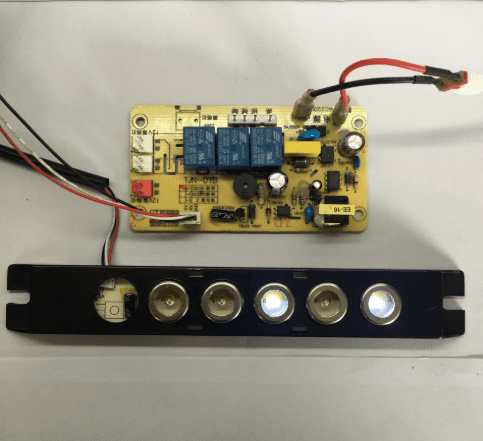

1. The solder mask layer is a PCB coating that covers copper traces and PCB material, serving as insulation and protection against short circuits and environmental factors.

2. On the solder mask layer, you need to create openings (windows) to allow for soldering or connecting PCB pads, as well as some through holes not covered by PCB ink for heat dissipation.

3. These openings on the solder mask layer are referred to as solder mask openings.

In simple terms, a solder mask opening (window opening) removes the paint layer from the circuit, allowing the underlying circuit to be exposed for tinning.

Why is solder mask opening necessary? For via holes, if the window is not opened, solder mask ink may enter and obstruct the hole. For holes that need to be open, they should be designed with windows. If a PCB does not have solder mask openings for components installed through holes, soldering those components can be problematic. The aperture opening not only facilitates soldering but also allows for accurate measurement on vias. For resistance welding and specific hole positions, a multimeter can be used to measure the through-hole.

Solder Mask Opening Design

1. Dimensional Design

In PCB manufacturing, the size of the solder mask opening should be larger than the exposed solder pad or copper area. Due to the skin effect, PCB oil around the solder mask opening accumulates, reducing the exposed area. Typically, the solder mask opening is 4 mils larger than the solder pad.

Is it necessary to set the solder mask opening size during PCB design? No, you only need to match the size of the exposed solder pad/through-hole, as the EDA tool will automatically adjust the solder mask opening size.

2. Solder Mask Opening Method for PCB Solder Mask Layer

In PCB design, openings can be set on both the upper and lower solder mask layers.

Upper/Lower Solder Green Oil Layer: This layer prevents tin from coating the copper foil and maintains insulation. Solder mask green oil windows can be set to access solder pads, vias, and non-electrical traces on this layer.

1) By default, PCB design will open the solder pad (OverRIDE: 0.1016mm), exposing copper foil and expanding by 0.1016mm. No design changes are recommended to ensure proper solderability during wave soldering.

2) By default, a window (OverRIDE: 0.1016mm) will be opened for the through-hole, exposing copper foil and expanding by 0.1016mm for wave soldering.

3) Non-electrical wiring can also be carried out on this layer, blocking the green oil and opening windows as needed. For copper foil wire, this enhances overcurrent capacity. Tin is added during the welding process.

The Difference Between Solder Mask Opening and Solder Pad

1. Different Uses

Solder mask opening targets the solder mask layer, creating areas for welding or plug-in installation. The solder pad targets the metal area on the circuit board, used for component soldering.

2. Different Meanings

Solder mask opening involves removing part of the solder mask layer to expose areas for welding or installation. The solder pad is a metal area on the circuit board, usually copper foil, used for soldering components.

Solder mask openings serve as testing points, improve heat dissipation, and can be tinned to enhance current-carrying capacity.

2. On the solder mask layer, you need to create openings (windows) to allow for soldering or connecting PCB pads, as well as some through holes not covered by PCB ink for heat dissipation.

3. These openings on the solder mask layer are referred to as solder mask openings.

In simple terms, a solder mask opening (window opening) removes the paint layer from the circuit, allowing the underlying circuit to be exposed for tinning.

Why is solder mask opening necessary? For via holes, if the window is not opened, solder mask ink may enter and obstruct the hole. For holes that need to be open, they should be designed with windows. If a PCB does not have solder mask openings for components installed through holes, soldering those components can be problematic. The aperture opening not only facilitates soldering but also allows for accurate measurement on vias. For resistance welding and specific hole positions, a multimeter can be used to measure the through-hole.

Solder Mask Opening Design

1. Dimensional Design

In PCB manufacturing, the size of the solder mask opening should be larger than the exposed solder pad or copper area. Due to the skin effect, PCB oil around the solder mask opening accumulates, reducing the exposed area. Typically, the solder mask opening is 4 mils larger than the solder pad.

Is it necessary to set the solder mask opening size during PCB design? No, you only need to match the size of the exposed solder pad/through-hole, as the EDA tool will automatically adjust the solder mask opening size.

2. Solder Mask Opening Method for PCB Solder Mask Layer

In PCB design, openings can be set on both the upper and lower solder mask layers.

Upper/Lower Solder Green Oil Layer: This layer prevents tin from coating the copper foil and maintains insulation. Solder mask green oil windows can be set to access solder pads, vias, and non-electrical traces on this layer.

1) By default, PCB design will open the solder pad (OverRIDE: 0.1016mm), exposing copper foil and expanding by 0.1016mm. No design changes are recommended to ensure proper solderability during wave soldering.

2) By default, a window (OverRIDE: 0.1016mm) will be opened for the through-hole, exposing copper foil and expanding by 0.1016mm for wave soldering.

3) Non-electrical wiring can also be carried out on this layer, blocking the green oil and opening windows as needed. For copper foil wire, this enhances overcurrent capacity. Tin is added during the welding process.

The Difference Between Solder Mask Opening and Solder Pad

1. Different Uses

Solder mask opening targets the solder mask layer, creating areas for welding or plug-in installation. The solder pad targets the metal area on the circuit board, used for component soldering.

2. Different Meanings

Solder mask opening involves removing part of the solder mask layer to expose areas for welding or installation. The solder pad is a metal area on the circuit board, usually copper foil, used for soldering components.

Solder mask openings serve as testing points, improve heat dissipation, and can be tinned to enhance current-carrying capacity.