Black Core PCB: Revolutionizing Electronics Manufacturing

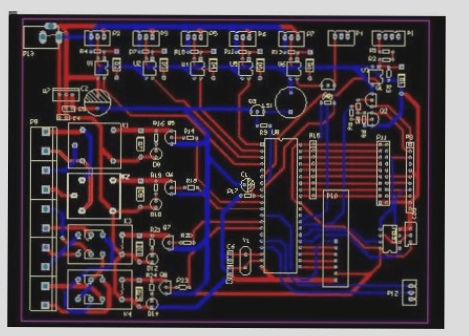

Black Core PCB stands out as a cutting-edge printed circuit board that offers unique advantages over traditional PCBs. Its distinct black substrate material nestled between copper layers has propelled it to the forefront of the electronics industry.

Why Opt for Black Core PCB?

Black Core PCB goes beyond its stylish appearance. It plays a critical role in shielding delicate components from light exposure, particularly sensitive sensors. While a black solder mask can partially block light, the use of black FR4 material ensures complete light isolation, safeguarding components from any light interference.

Benefits of Black Core PCB

- Efficient Heat Dissipation: Black Core PCB utilizes a black thermal conductive substrate, enabling superior heat dissipation. This feature aids in stabilizing circuit components by effectively absorbing and dispersing heat, thereby enhancing system reliability, especially in high-power applications and heat-sensitive devices.

- Durability and Longevity: Black Core PCBs excel in durability, adapting well to prolonged usage. Their robust material composition withstands temperature variations without compromising, ensuring longevity and reducing maintenance requirements, ultimately leading to long-term cost savings.

- Enhanced Signal Transmission: The black core FR4 material with its lower dielectric constant and dissipation factor enhances signal transmission performance. This results in reduced signal losses, minimal attenuation, and improved signal integrity. Additionally, the material aids in managing heat during signal transmission, reducing thermal interference.

- Aesthetic Appeal: Black Core PCB offers an attractive visual appeal, making it an ideal choice for consumer electronics where aesthetics play a crucial role. The sleek black surface conceals copper traces, contributing to a modern and sophisticated appearance that complements other components and enhances overall product aesthetics.

Key Considerations for Black Core PCB Design

- Effective Heat Management: Proper heat management is essential for designing Black Core PCBs, particularly for high-power applications, to ensure safe operation and prevent performance degradation due to overheating.

- Material Compatibility: Selecting compatible materials is crucial to maintain reliability and prevent operational failures or reduced longevity in Black Core PCB designs.

- Signal Transmission Stability: Ensuring stable signal transmission is vital for high performance, especially in Black Core PCBs. The efficient heat dissipation properties of these boards aid in maintaining smooth and interference-free signal flow.

- Uniform Power Distribution: Achieving even power distribution is critical for reliable PCB functionality to prevent voltage imbalances that could lead to circuit failure or performance issues.

Applications of Black Core PCB

- Automotive Electronics: Widely used in automotive systems like infotainment, dashboard controls, and ADAS, Black Core PCB combines functionality with aesthetics.

- Consumer Electronics: Ideal for premium consumer electronics such as high-end audio devices, smartphones, and tablets, where visual appeal is paramount.

- LED Lighting: Enhances contrast and lighting effects in LED applications, making it a preferred choice for impactful designs.

- Industrial Control: Ensures reliable electrical connectivity in industrial control systems while maintaining a professional appearance in industrial settings.

- Gaming and Entertainment: Elevates the gaming experience in consoles and arcade machines with its sophisticated black design.

Understanding Black Core PCBs for Aesthetic and Design Needs

Black Core PCBs are often chosen for their visual appeal and specific design requirements. While they offer aesthetic enhancements, their functionality is generally on par with standard PCBs. The decision to opt for Black Core PCBs depends on the specific needs of the industry or product.

Explore Wellcircuits GF113 Series (FR-4-BK) A2 Grade Copper Clad Foil

- Material: FR-4-BK

- Grade: A2

- Copper Clad Foil

Wellcircuits provides options for both clear soldermask and Black Core PCBs. When placing an order, customers can specifically choose Black FR4 (black core) through the Customized Services and Advanced Options in the PCB Specification Selection.

It’s important to note that this material is not commonly stocked and needs to be procured separately. Consequently, production timelines may be extended, and costs could be higher. For details on pricing and delivery schedules, feel free to reach out for more information.

For placing orders or further inquiries, please visit the PCB Instant Quote page. For any questions related to PCBs or PCBA, you can contact us via email at info@wellcircuits.com.