Understanding DOUBLE SIDED SMT ASSEMBLY Technology

- DOUBLE SIDED SMT ASSEMBLY technology is a key player in the electronic production industry, involving small and commonly used components like capacitors and resistors.

- SMT, or Surface Mount Technology, is the primary method used in PCB assembly.

- IBM Corporation played a vital role in pioneering SMT technology in the 1960s and its widespread adoption in the late 1980s.

- By the late 1990s, surface mount devices dominated high-tech electronic printed circuit assemblies.

The Core of SMT: Surface Mounting Technology

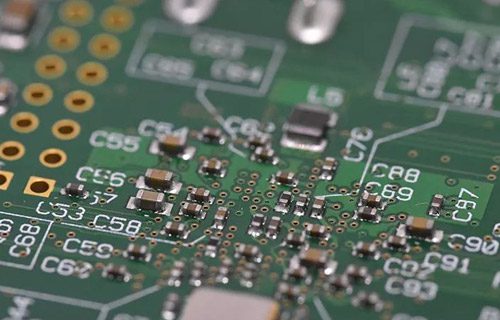

SMT, an acronym for Surface Mounting Technology, is the foundation of modern circuit board manufacturing. It involves mounting electrical and electronic components directly onto the PCB surface.

Automatic and semi-automatic assembly lines ensure precise placement of components, leading to high accuracy in the assembly process.

The Process Behind SMT Technology

PCBA, or printed circuit board assembly, is the key to enabling various functions in modern electronic devices by integrating different electronic components on a small PCB substrate.

Through the use of SMT technology, components are attached to the PCB surface with solder paste, reducing their physical size and enhancing efficiency.

The Evolution of Electronic Assembly

SMT machines, equipped with advanced technologies like image processing, have revolutionized the circuit board manufacturing industry, replacing traditional through-hole technology.

Surface Mount Devices (SMDs) are the result of this technological shift, offering smaller component sizes and improved performance.

The Benefits of Surface Mount Technology (SMT) in PCB Assembly

Surface Mount Technology (SMT) has revolutionized electronic component assembly, allowing for increased automation, cost reduction, and improved quality. This method enables more components to be placed on a circuit board, optimizing space utilization.

SMT components are typically smaller than through-hole components, offering various styles of leads or contacts, such as flat contacts or solder ball matrix (BGA). The high degree of automation in SMT technology enhances production efficiency and capacity.

Modern SMT machines ensure precise component placement through advanced image processing technology, minimizing errors during the pick-and-place process.

Understanding SMT Lines and Production

SMT lines represent a new era in electronic circuit production, replacing bulky wire connections with compact designs. Integrated Circuits (ICs) mounted on smaller PCBs alongside other components define the essence of SMT production lines.

These production lines vary in automation levels, categorized as automatic or semi-automatic, and in scale, ranging from small to medium-sized setups.

Chip Mounting Techniques in SMT

Chip mounting processes in SMT lines involve scanning solder alloys, inserting and installing Chips, heating, cooling, and error checking and fixing. These steps ensure the proper functioning of the assembled components.

Exploring SMT Devices and Components

Passive SMT Components

Passive SMT components like resistors and capacitors come in standardized package sizes, ranging from 1812 to 0201. While less common now, they find usage in applications requiring larger components.

Transistors, Diodes, and Integrated Circuits

Transistors and diodes in SMT are housed in small plastic packages, with leads for board connections. Integrated circuits come in various packages depending on the required connections, ranging from basic logic to VLSI processors with hundreds of pins.

BGA packages offer direct connections below the chip, suitable for diverse applications.

Pros and Cons of SMT Technology

Advantages of SMT

- Increased automation and production efficiency

- Cost reduction and improved quality

- Optimal space utilization on PCBs

Advantages of SMT Technology:

- Mounting components on both sides of the board reduces component size and saves space.

- Simple and fast assembly process.

- Automatic correction of small errors during assembly.

- Reduction in lead contact resistance and resistance.

- Durable and resistant to external forces over time.

- Cost-effective compared to through-hole components.

- Diverse range of products meeting various user needs and applications.

- Effective in reducing lead resistance and contact resistance.

Challenges of SMT Technology:

Despite its advantages, SMT technology faces some challenges that require future improvements:

- Elaborate manufacturing process requiring significant time and investment.

- Difficulty in handling small component sizes leading to assembly errors and damage.

- Less suitable for components requiring frequent connections and disconnections.

- Manual repair is challenging due to the small size of components.

Applications of SMT Technology:

In the electronics industry, SMT surface mounting technology has largely replaced traditional through-hole PCB assembly methods. Components are securely attached to the PCB through soldering. Different brands have developed their proprietary techniques for mounting chips on SMT assembly lines.