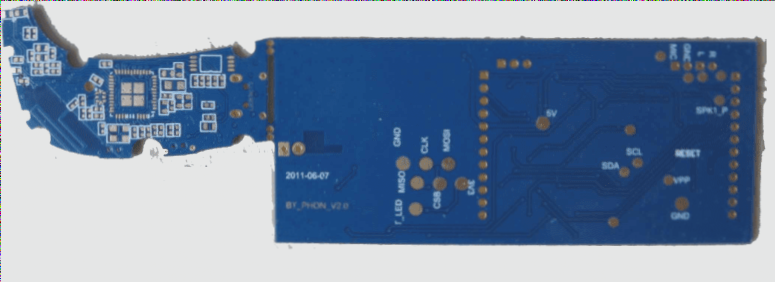

An embedded PCB integrates circuit components on its surface on a PCB assembly. These components could be capacitors, inductors, resistors, etc. They are embedded in various layers to enhance functionality and the system performance further. Commonly, these circuits could be used in the following applications:

- Luxury mobile phones

- Hospital equipment

- Financial devices

- Automotive electrical power and computer controls

- Arts and crafts

- Camcorders and home video games

- Medical devices

- Industrial automation equipment

- Wireless communication devices

- Vacuum cleaners and industrial cleaners

- Toys

- Security devices

Additionally, embedded PCBs are used in telecommunications devices to fit different bandwidth requirements, especially when the signal transmission is modified in transmission over the PCB to improve the transmission speed. In contrast to conventional electronic devices, embedded PCBs are immune to external noise and voltages.

The Assembly Process for Component Embedded Printed Circuit Board

This is the main assembly process that is commonly used for incorporating the components. The components go inside the PCB assembly inside the layers and layers of the PCB. The boards are a flexible surface for assembly. This involves several processes. Here, the assembly procedure is a number of stages.

Stage 1: Preparation

This involves the development of a concept design, prototyping, and the order to collect relevant materials. Additionally, to ensure the PCB has sufficient strength and thickness to ensure its endurance. All this has to be discussed with the client before finalizing the design.

Stage 2: Modification of the Concept Design

It is an initial stage to finalizing the PCB concept. This involves modification of the development layout. In other words, this involves starting with the PCB board size by modifying the board sizes of the top layer, the bottom layer, and the layer between them. The design might be revised to suit the needs of the customer. It is common to have some changes to the design, so, no need to worry. However, those few that must not be done, they must be clarified.

Stage 3: Designing the PCBs

This stage involves the development of the schematics of the PCB, the component placement, and the selection of materials to ensure the properties and functions of the PCB are meet. The process involves the assignment of the order for the components to be placed in the PCB. This involves the choice of material used, size, and the distribution of components. The next step after this would be the production of the components according to the requirements of the customer. The entire process usually takes from a month to a few months.

Stage 4: Ordering the Components

This involves ordering the components for production. After the ordering, the production could begin, which takes from a few months to about a year, depending on the complexity of the design.

Stage 5: Product Release

The products could be released at the end of the process, which normally takes about a year. Finally, the customers get the products they order.

Placement of Components on PCB Assembly

Due to the layers involved in this process, the connections are secured by components, or their base, which are packed on the PCB. When they are packed, they can easily be installed. The components are secured on the PCBs by fasteners such as screws, eyelets, flanges, springs, clamps, hinges, zippers, and adhesive.

Embedded PCBs have a separate space between the board layers for the placement of the components, for the components to withstand the pressure, and to ensure their viability. Some of these connection points are not designed to withstand the pressure of the components, so they must be reinforced or clamped.

Signal Transmission Over an Integrated Circuit

Embedded PCBs are widely used for signal transmission over an integrated circuit. By using these PCBs, any electrical signal transmission could be guaranteed by keeping the signal safe. Embedded PCBs are suitable for not only discrete signal transmission but also for analog signals.

This is because the electromagnetic waves are converted from analog signals to digital signals by an appropriate function or process. If we let the signal to pass in the analog system and we are not qualified to provide the correct function, our signal transmission can cause many errors and mistakes. In this case, we have to be qualified to provide the correct function to the analog system.

Recognition of Different Kinds of Connections

It is also important to recognize the different kinds of connections for an embedded PCB. One type is the PCB ground connection. This means the solid grounding connection of the PCB. The other type is the RF (radio frequency) ground connection. This is the non-solid ground connection.

Capability to Transmit a Signal

One important aspect of embedded PCBs is the capability to transmit a signal with the best signal-to-noise ratio. In other words, this means the signal transmission is the best. In this case, if the signal transmission is high, it will be processed by the electronics fast. If the transmission is low, the electronics will reject it because it will transmit too much noise, which would cause the system to malfunction.

Design of the Components of Embedded PCBs

One important distinction of an embedded PCB is the use of high-quality connectors. These connectors must also be able to provide the required mechanical strength to the PCB. The design of the components used in the embedded PCB should be carefully planned so that the overall system has the strength and endurance to meet the requirements of the customer. The PCBs manufactured from low-cost materials should be paired with high-quality connectors for a complete system.

Benefits of Embedded PCBs

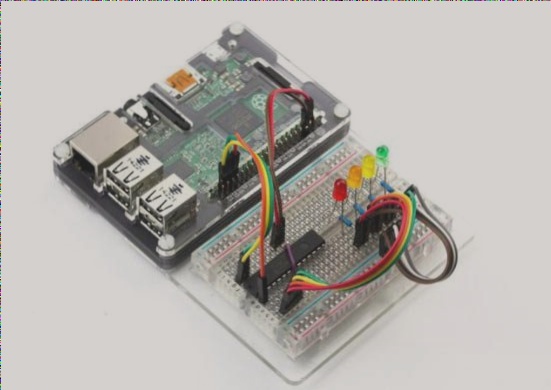

Embedded PCBs are compact, flexible, and simple to manufacture in comparison with conventional PCBs. They are also immune to external noise, and thus minimize vibration, wear, and failure, which are common faults in conventional circuit boards. The semiconductors are the main components of embedded PCBs, and they are less prone to damage and short circuits compared with the other components of a PCB.

Furthermore, embedded PCBs can be embedded on the PCB at various layers, which further increases the PCB’s strength and robustness. Moreover, they do not contain multiple layers of components, which reduces the PCB’s dimensions and complexity. Let’s discuss the five unique benefits of embedded PCBs:

- Less complex

Embedded PCBs are an ideal choice for circuit applications where conventional PCBs are out of the question. Their advantage is that they are exceptionally versatile. They may be used in the construction of any electronic device.

High-quality embedded circuit components are less prone to damage and short circuits compared with the other components of a PCB. These embedded components are implanted on the PCB without compromising the PCB’s flexibility and wearability.

- Small and portable

Embedded PCBs are lightweight, flexible, and easy to carry and travel with. They are compact in size. Hence, they are a great choice for small portable devices.

They are also extremely cost-effective as compared with conventional PCBs. Further, the circuit components can be seamlessly embedded on the embedded PCB without any compromise on the reliability of the circuit.

- Smooth production process

Embedded PCBs are made up of chip-on-board (COB), which is a very low-cost, energy-efficient, and less complex production process. The finished circuit component is also easy to be embedded into the PCB using a single process step and without any changes in the product layout, thereby avoiding any production delays.

- An eco-friendly solution

Embedded PCBs are the first choice for making smaller, environmentally-friendly products such as household appliances and medical devices. These products are commonly used in the following applications:

- Medical devices

- Alarm systems

- Trunk applications

- Gaming consoles

Due to their minimal nature, Embedded PCBs do not need conventional metal frames and components. Further, the more innovative and eco-friendly embedded PCBs come with an eco-friendly battery and an easy-to-use touchscreen.

- Compact design and manufacturing

Embedded PCBs are the least-exposed PCBs for making smaller products because they contain fewer components. They are also smaller in size than conventional PCBs.

Embedded PCBs may also be used in the manufacturing of circuit boards for use in:

- Microelectronic systems

- Computer and computer-related equipment

- Sensors

- Computer peripherals

Based on the device, the system, and applications, the process and cost of PCBs and embedded PCBs can be different. However, the benefits of embedded PCBs are quite clear. Hence, these PCBs are the newest, most cost-effective, and versatile PCBs, which can be used in a variety of applications.

- Security is guaranteed

Embedded PCBs are an ideal choice for data security. These PCBs are easier to control than conventional PCBs.

These PCBs are embedded directly on a circuit board, which is an ideal place for taking secure data. Moreover, they are flexible and can be manipulated to make the circuit board to fit the desired size.

Besides these advantages, there are several benefits of the embedded component PCB that you can’t get with conventional PCBs.

Wrapping Up:

Embedded PCBs is the emerging technology for prototyping and manufacturing small-scale electronic products. These PCBs are manufactured with an extremely low-cost, eco-friendly production process and cost-effective components that do not require metal frames and conductive materials. The PCB manufacturing companies have used various components such as LED chips, resistors, and copper traces in embedded PCBs to make the smaller-sized components.

These PCBs are made up of chip-on-board (COB), which is a low-cost, energy-efficient, and less complex production process. The finished component is easy to be embedded in the PCB using a single process step and without any changes in the product layout, thereby avoiding any production delays.