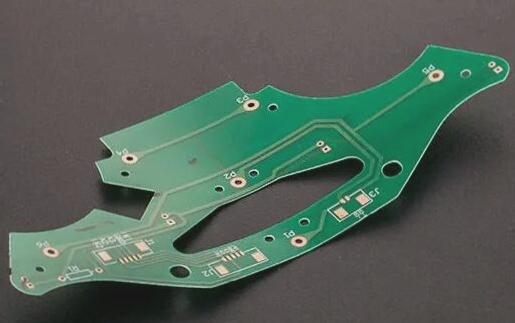

Flexible PCBs are very common these days, but that doesn’t mean they don’t have their downsides. One of the main things is that they can be too flexible to handle properly. To help with this, FPC stiffeners are added to them.

In flex circuit boards, the final step of fabrication is adding stiffeners. It makes the board a little more rigid, which is useful when handling the board. A completely flexible circuit can be hard to handle, so the stiffener not only keeps the parts together but it also gives it structure.

The stiffeners act as a kind of adhesive, and there are many different types considering their usage and placement. Although all of them are metals and help in heat dissipation. To know all about the FPC stiffener types, thickness and uses, read on. We cover it all here.

What Is FPC Stiffener?

FPC stiffener is an electronic material that is applied to the circuit where two parts are connected. It acts as a bucker. Though it is an electronic material it doesn’t have an active role in making the circuit. The stiffener material is a metal, and it helps in heat dissipation. It also acts as mechanical support.

Having FPC stiffeners in your PCBs makes its performance better and also makes it more reliable. One thing which people confuse about is that all flexible circuit boards will need stiffeners but keep one thing in mind not all flexible circuits require FPC stiffeners.

Why Do You Need To Put In FPC Stiffener?

One might think that why would you need to put in FPC stiffeners when it doesn’t even play a part in the electronic structure, and the circuit can work almost alright without it. So here are a few reasons we’ve penned down on why you need to put in FPC stiffeners.

- When you are applying force on any solder or pad, the force goes all to the terminal point, and there is a very high chance of breakage. So to prevent all the force from being applied there, if we reinforce the stiffener layer there, it makes it a lot stronger.

- If a reinforcing plate is attached or a stiffener is applied, the small welded parts stay in place on the pad. If it is not present, the circuit board is too flexible, and there is a chance of the parts falling off or what we call de-mounting.

Materials Used In Making FPC Stiffeners

There are many different types of stiffener materials used. One thing common in all of them is that they are all metals and good in heat dissipation. However, selecting the right one according to your needs is very important, keeping in mind the benefits of each.

Let’s look at the few common ones used.

- Polyimide Stiffeners

These stiffeners are commonly known as gold fingers. They are the most commonly used type of stiffeners. Polyimide stiffeners can be easily inserted into ZIF connectors, and they are the aptest type for ZIF connectors.

They increase the bending area tolerance and contour the point of contact. This is the reason the components become stronger but also not too thick. It can even be added in the end, and if any part wears off or shows resistance, you can always add it in the later stage. If the PCB circuit is not laminated, you can add it at any stage without disturbing the circuit.

- FR-4 Stiffeners

FR-4 stiffeners are also called the CCL of stiffeners. You can add it easily to the holed plates. It provides a very flat surface with it applied on one surface of the board. The FR-4 stiffeners generally create a border on the board, which saves it from any further damage. FR-4 stiffeners make sure that the holes are filled up to 0.3mm and not bigger than that to ensure good alignment.

- Aluminum and Stainless Steel Stiffeners

Aluminum and stainless steel stiffeners are needed where you need to avoid resistance due to corrosion. These two materials require proper milling, drilling, and then shaping. When inserting the circuit, the process is very long, going through laser-cut, registration and precut, etc.

After all these processes, the end product is very durable, and considering this much effort on it, the process is expensive as compared to all other types of FPC stiffener insertion.

- Multiple PCB Stiffener

Sometimes the solder joints need to be stiffened, but with one material, the thickness exceeds. So to keep the thickness in check and also make sure the product isn’t too weak, multiple layers of PCB stiffeners are applied.

They are added in the following order if you are going for multiple-layer FPC stiffeners:

- FR-4

- Adhesive

- Polyimide

- Copper

- Polyimide

- Copper

- Polyimide

FPC Stiffener Thickness

You’ve read about the stiffener materials used. Let us look at the usual thickness of these materials used in PCB circuits.

| STIFFENER MATERAIL | THICKNESS |

| Polyimide (PI) | 0.05mm 0.075mm 0.1mm 0.125mm 0.15mm |

| FR-4 | 0.2mm 0.3mm 0.4mm 0.5mm 0.6mm 0.7mm 0.8mm 1.0mm 1.2mm 1.5mm |

| Aluminum | 0.2mm 0.25mm 0.3mm 0.35mm 0.4mm 0.5mm 1.5mm |

| Stainless steel | 0.15mm 0.2mm |

Features Of FPC To Consider When Putting In Stiffeners

Before we talk further about FPC stiffeners, let’s first look at the features of FPC. FPC basically stands for a flexible printed circuit which is also referred to as a flex circuit. The circuit has many parts and one of the most critical parts or features to consider when putting a stiffener is to align it well and, if necessary, put a reinforcing plate.

Usually, the stiffeners are placed on the same side as the flex circuit, but sometimes, you have to put the stiffener on both sides for better rigidity. This requires many lamination cycles to keep it in place. This will cost you a lot more than the single layer. So you have to make sure which one you are going for and whether it suits your needs or not.

How Are Stiffeners Applied?

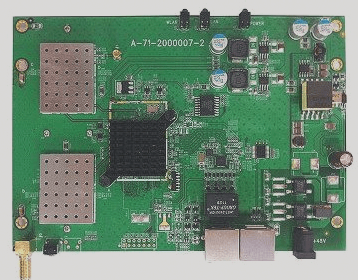

The manufacturers make sure the stiffeners are applied in such a way that it lasts you a long time and it’s reliable. Usually, the stiffeners are added in plated-through holes, and they are placed on the same side of the board where all other components are inserted.

There are many different approaches to the assembly of components. It is done very carefully so that in the longer run, these configurations are easy to work with. The two main approaches to applying stiffeners in a flexible print circuit are as follows:

- Pressure-Sensitive Adhesives

These stiffeners are attached to the circuit by only applying pressure, and it is not as strong, so they can be easily removed when needed without damaging other components. This type of FOC stiffener doesn’t endure too much force, which is why they are used in TVs, laptops, and other household electronics. It generally takes lesser time, and it isn’t too expensive.

- Thermal Bonding

As the name indicates, the FPC stiffener is added with the help of heat. It also uses high pressure, and the bonding is way stronger than the other type. Such bonding is used in class 3 IPC products like military applications, avionics, etc.

The process is quite expensive and takes time, but the end product is very durable. The only drawback is that the bonding is so strong that it breaks or damages other components if tried to remove from the flex circuit.

Benefits And Industrial Uses Of FPC Stiffeners

We have already read all about the types and placements; let us look at some of the benefits they serve other than being a great help in the industrial production of PCB circuits. Their usage is so diverse, considering their easy application. Here are some uses and how they benefit in the longer run.

- When they are repeated insertions or connections, FPC stiffeners serve to keep it rigid and don’t build too much stress.

- They avoid localized bend constraints in flex circuits.

- They form a flat surface for the placement of SMT pads and other components.

- The heat is equally dissipated through steel or aluminum stiffeners.

- FPC stiffeners minimize the overall stress on the circuit.

- They prevent the connector parts from falling off.

- FPC stiffeners help in maintaining the proper thickness of the circuit board.

- If you want to enforce any specific area of the circuit board, adding a stiffener makes it easier.

- FPC stiffeners don’t need to apply everywhere, so it is easier to regulate their thickness where needed.

- They help in fulfilling the ZIF connector requirements.

- It avoids stress being applied at any terminal position; all of it is equally divided through the board.

- Overall, the FPC stiffeners allow better board handling and can be easily put in the electronic devices without worrying about their delicacy.

Bottom Line:

If you want a flawless assembly and smooth working, it is best to add an FPC stiffener to your flex circuit. There are many different types of arrangements depending on what type of end product you want. So when getting it, discuss it with your manufacturer and look out for the most reliable and best options available.