What is High-Pressure Gas Soldering

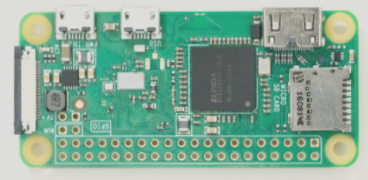

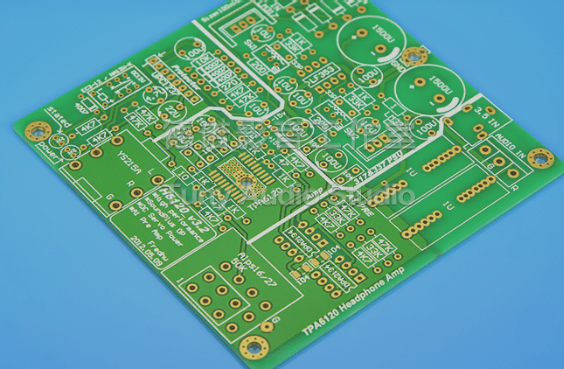

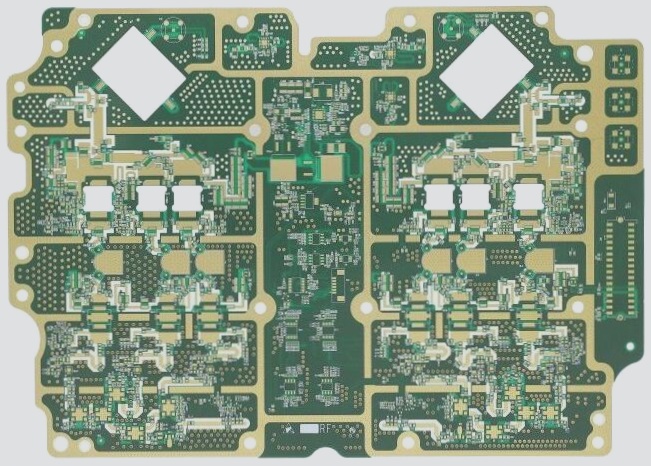

Solder paste, a unique combination of minute metal solder particle and slimy flux, is exclusively known for its usage in the printed circuit board or PCB manufacturing. This special paste attaches the mount particles to pads on the board and creates a stable bond between two different work elements. In this process, the sizes of the metal particles and the density of the flux play a significant role and decide the outcome of the solder paste.

Along with these two, the exact temperature is equally essential as certain elements cannot withstand a high temperature. Hence, low-temperature solder paste that can easily melt at a heat below 180° C has become extremely beneficial in some instances.

To know more about low-temperature solder paste, its applications, and other vital features of the solder paste, keep reading this article till the end.

What is Low-temperature Solder Paste?

Low-temperature solder paste, without a doubt, is a very extraordinary blend of tiny metal particles and sticky flux. This easily dissolves even at a temperature under 180° C. Usually, the typical solder paste temperature extends over 250° C to 240° C, which often becomes destructive for some delicate particles.

As mentioned before, solder paste should have the right consistency as well as the right temperature to secure the performance of the PCB. Temperature over 240° C is too much to handle for some elegant and sensitive machines, especially for the heat-sensitive ones.

On the other hand, the portable and miniaturized layouts of several devices can’t tolerate the extreme heat of the typical solder paste. Therefore, low temp soldering is the only effective way to provide security as well as great execution to these devices.

Additionally, low-temperature soldering is noticed during step soldering as the printed circuit board of that particular device already contains some sort of soldering in it. In this process, the PCB can easily get extra components attached to it, confirming the full protection of the previously performed soldering.

What temperature does solder paste melt?

Solders containing different properties follow the exact form of melting in which a hard thing becomes liquefied. A solder can melt anywhere between the temperature of 90° C and 450° C in general. Therefore, the melting point of any solders changes accordingly with your selection of the solder amalgam, the heat resistance power of particular devices, etc.

Solders are mainly divided into two particular sections:

- The Eutectic solder

- The Non-eutectic solder

In the first one, the alloys can melt at a sole heat which is a very necessary feature in various industrialized procedures. On the other hand, the non-eutectic solder cannot melt at a single temperature. Some non-eutectic alloys have a melting range of 2° C to 3° C; some have 75° C as well.

Additionally, ‘hard or silver soldering’ is noticed when a Solder paste melting point crosses 450° C and more.

[wpi_designer_button twin_id=2164]

Application of Low Temp Solder Paste

The practical use of low temp solder paste is seen in the electronic assembly industries in large numbers. Let’s see how and when a low temp solder paste is used.

Heat-sensitive designs of devices:

Some devices cannot tolerate too much heat and are very delicate and fragile. Being heat-sensitive, these devices can easily damage whenever they are overheated. Therefore, by using low-temperature solder paste, the important components of the circuit board are attached with a temperature within 180° C.

Step Soldering:

Another significant application of low-temperature solder paste is observed in the field of step soldering. Step soldering is nothing but regular soldering in which the circuit board already contains two or more permanent soldering hence the heat resistance power of the PCB decreases. If a higher temperature is used instead of Low-temperature solder paste, the portions of the device get affected or even can damage forever.

Other Applications of Low Temp Solder Paste

- Furthermore, low temp solder paste is used to remove the war page of thinner flakes that can be caused by higher heat reflow.

-

- To prevent head-in-pillow or HIP, NOW failures in the considerable area display electronic devices.

- Low- Tg flex circuitry in mobile phones, cellular devices, internet connections, etc

- To fill in the deformities in mating grounds and establishes an airtight seal.

- In switches, barometer, heat transfer systems, and other thermal designs

These, in short, were some applications of low-temperature solder paste.

How do you use low temp solder paste?

To use Low temp solder, all you need is the right amount of flux, right temperature, and last but not least, proficiency and skill to attach certain work pieces.

Tin/bismuth, tin/indium, or tin/bismuth/silver are the commonest selection because of their low melting rate of 150-170° C. But you have to be very careful while blending these components and have to follow some precautions. This SnBiAg alloy has an impressive melting point of 138° C that assures a maximum reflow of heat between 170° C and 180° C.

Although the mixture of tin, bismuth, and lead has the lowest melting point of 95° C, yet it can cause delinquency in the joint as it tends to melt easily in the natural heat. So, you have to select the components with utmost care and proficiency; otherwise, you can face serious failure or damage.

Once your low temp solder flux or paste is ready, you can use it with the help of a special syringe or some DIY tool to test and efficiently join your components on the PCB without damaging other elements.

How WellCircuits the PCB team can help you?

I hope that you have collected enough information about low-temperature solder paste, its application, the right temperature of solder paste, and how to use it precisely. If you search for a perfect and delicate PCB design, you won’t possibly find a better option than low-temperature solder paste.

To attain the best service, you need a professional intervention of the WellCircuits PCB team. Therefore, feel free to contact the professionals in case you need to explore more about low-temperature solder paste.

[wpi_designer_button twin_id=2164]