The Benefits of Immersion Silver Surface Treatment in PCB Manufacturing

Pure silver is a top choice for surface treatment in PCB manufacturing due to its exceptional properties. Silver is soft, highly ductile, thermally and electrically conductive, and resistant to oxidation. These qualities make silver an ideal material for ensuring optimal PCB performance and longevity.

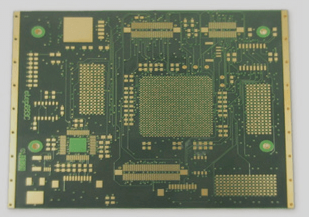

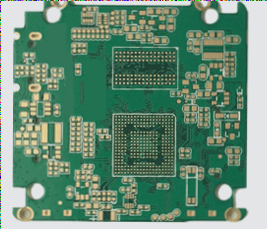

Immersion Silver Process

One popular silver-based surface finish is Immersion Silver. This process chemically deposits a thin layer of silver (usually 0.1 to 0.5 micrometers thick) onto the copper surface. It protects against oxidation and significantly enhances solderability.

Environmental and Performance Benefits

The Immersion Silver process is environmentally friendly and complies with RoHS standards, making it a sustainable choice for manufacturing. It offers superior surface planarity, making it ideal for high-density circuits and fine-pitch SMT applications. Its low signal loss at high frequencies ensures reliable performance in high-speed circuits.

Considerations and Limitations

While Immersion Silver provides excellent performance, it is sensitive to contamination from chlorine and sulfur compounds. Careful handling is necessary to prevent scratches or damage to the silver layer. Silver coatings can degrade when exposed to air for extended periods, so it’s best to use Immersion Silver PCBs within 48 hours of production.

Although Immersion Silver has great electrical properties, its mechanical strength is not as robust as finishes like ENIG due to the lack of an underlying nickel layer.

Contact Us

If you have any inquiries about PCB or PCBA services, please reach out to us at info@wellcircuits.com.