Understanding OSP in PCBs

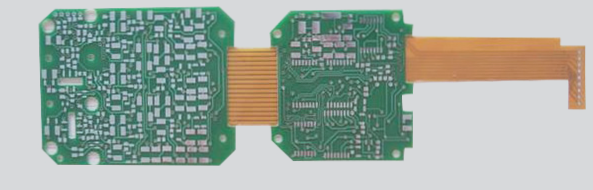

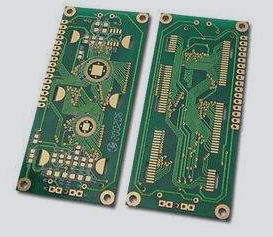

Organic Solderability Preservative (OSP) is a popular surface treatment for PCB copper that meets RoHS standards. Essentially, OSP entails applying an organic layer to the clean copper surface of a PCB to protect it from oxidation and moisture until soldering.

It’s crucial to handle OSP-coated PCBs with care to avoid damaging the sensitive coating, which could affect solderability. Proper storage and gentle handling are key to preserving the quality of the finish.

OSP involves using a water-based organic compound that bonds selectively to the copper, forming a thin, eco-friendly protective layer. This method not only safeguards the copper but is also cost-effective and ideal for mass production.

In essence, OSP is a great alternative to lead-free HASL for PCB surface finishes that prioritize flatness, ease of manufacturing, environmental friendliness, and cost-efficiency, all while ensuring reliable solderability.

If you have any inquiries about PCBs or PCBA, don’t hesitate to reach out to us at info@wellcircuits.com.