Understanding PCB Components and Integrated Circuits

Circuit and Pattern

The circuit in a PCB design provides conduction between components, often with a large copper area for grounding and power. Routing and patterning are typically done simultaneously.

Dielectric Layer

The dielectric layer offers electrical insulation between the circuit and other layers, acting as a substrate.

Hole (Through hole / Via)

Through holes enable connections between circuits on multiple layers, with larger ones for component insertion and non-through holes (nPTH) for surface-mount components or securing screws.

Solder Resist / Solder Mask

Areas not needing soldering are covered with a layer, like epoxy resin, to prevent solder adhesion, avoiding short circuits. Solder masks are typically green, red, or blue.

Silk Screen (Legend/Marking/Silk Screen)

Used for labeling components on the circuit board, aiding in maintenance and identification post-assembly.

Surface Finish

To protect copper areas needing tinning, various surface finishes like HASL, ENIG, Immersion Silver, Immersion Tin, and OSP are used, collectively known as surface treatments.

PCB Characteristics

- High Density: Advances in integrated circuit integration have led to high-density PCBs.

- High Reliability: PCBs undergo rigorous tests for reliable long-term operation.

- Design Flexibility: PCB designs can meet specific requirements efficiently.

- Producibility: Modern techniques enable large-scale, consistent production.

- Testability: Comprehensive testing ensures product quality and longevity.

- Assemblability: PCBs support standardized assembly for efficient production.

- Maintainability: Standardized components allow for easy replacement and system recovery.

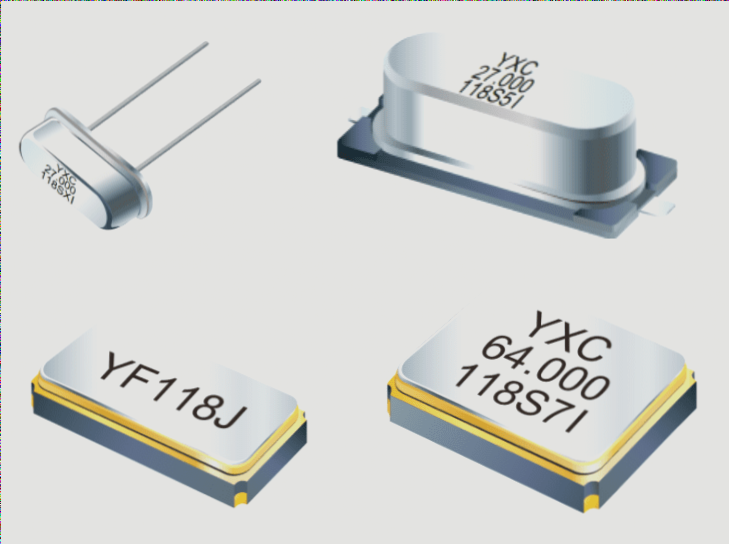

Integrated Circuit Features

Integrated circuits offer advantages like small size, light weight, long lifespan, high reliability, and excellent performance, suitable for mass production in various electronics applications.

Difference Between PCB and Integrated Circuits

An integrated circuit (IC) is a chip, while a PCB serves as the board connecting components, including ICs. PCBs are the substrate for ICs, found in almost every electronic device.

PCB vs Integrated Circuit: What You Need to Know

At its core, a printed circuit board (PCB) acts as the foundation that provides physical support and electrical connections for components. On the other hand, an integrated circuit (IC) consolidates multiple circuit functions onto a single chip. Should an IC sustain damage, the entire chip is affected. In contrast, a PCB allows for individual components to be soldered and replaced independently if they become faulty, simplifying system repairs and upgrades.