PCB Assembly: The Heart of Modern Electronic Devices

- Printed Circuit Board Assembly (PCBA) is the driving force behind the exceptional performance of our electronic gadgets.

- PCBAs consist of copper traces that electrically link components and connectors, enabling seamless communication.

- These boards, made of insulating materials like fiberglass, play a crucial role in the functionality of electronic devices.

Understanding PCBs and Their Applications

A Printed Circuit Board (PCB) is a thin board with a layer of copper, allowing components to be soldered onto it. Single-sided PCBs have copper on one surface, while double-sided PCBs have copper on both surfaces.

The Significance of PCB Assembly

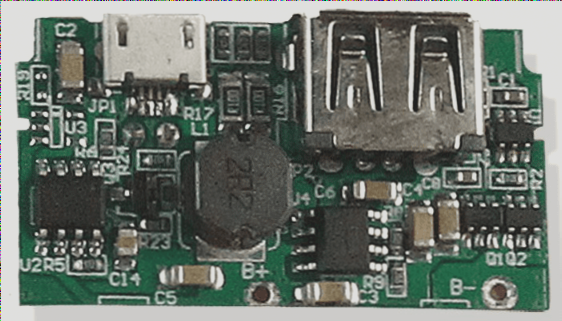

PCB Assembly involves fixing components onto a PCB to enhance its functionality. Without these components, a circuit board remains incomplete.

Applications of PCBA

PCBAs are used in various industries such as automotive, medical equipment, and electronics. They can be found in devices like motherboards, TVs, mobile phones, and more.

The Evolution of PCB Assembly

In response to the growing demand for electronic devices, the manufacturing process of PCBAs has become more complex. The adoption of Surface Mount Technology (SMT) has improved product quality and yield performance.

Key equipment like reflow ovens, stencil printers, and placement machines are crucial in the production of PCBs. Quality assurance processes like in-circuit testing and automated optical inspection help prevent failures.

Ongoing research aims to automate and streamline these processes for more efficient and proactive manufacturing practices.

PCB Assembly: A Comprehensive Guide

PCB assembly, also known as printed circuit board assembly, is a crucial process in the manufacturing of electronic devices. It involves connecting various modern bare PCBs and electronic components to create functional gadgets. To enhance productivity, automated processes have been implemented for efficient PCBA planning.

The PCB Assembly Process

During PCB assembly, bare PCBs are coated with solder paste, and surface mount components are attached to them. The melted solder paste in a hot oven is used to connect the boards and components. Through-hole technology (THT) and Surface Mount Technology (SMT) are the primary methods employed in attaching components to PCB boards.

Why Choose WellCircuits PCB Assembly?

WellCircuits is a renowned PCB solutions provider offering top-quality PCB designs. With experienced professionals and a focus on customer requirements, we deliver customized printed circuit boards tailored to your needs.

Surface Mount Technology (SMT) Application

Modern industries are increasingly adopting Surface Mount Technology (SMT) for PCB assembly. Techniques like solder paste reflow and wave soldering expedite the assembly process, making it ideal for mass production. Traditional pin mounting methods are also utilized alongside SMT.

Various technological operations are performed based on the PCB’s signal layers and purpose. Etching processes, including subtractive and additive technologies, are used for single- and double-sided boards to create conductive pathways.

Automatic PCB Assembly

Automated assembly of PCBs involves specialized equipment for efficient component placement. The advantages of automated assembly include precision, speed, and consistency in mass production scenarios.

PCB Assembly Techniques: Wave vs. Selective Soldering

In the realm of printed circuit board assembly, two primary soldering methods are commonly employed – wave soldering and selective soldering. Wave soldering involves immersing the bottom surface of the PCB and component leads into solder, ideal for high-volume production in large industries. To protect the board’s integrity, a protective layer is applied.

Exploring Selective Soldering

Selective soldering, a newer technology introduced in the nineties, offers precise mounting of output electrical components with high efficiency. This method is cost-effective and eliminates the need for post-solder flux cleaning due to its targeted application.

Partner with a Leading PCB Assembly Company

As printed circuit boards form the foundation of modern technology, various assembly techniques are utilized to meet consumer needs. Our company specializes in PCB development and assembly, ensuring competitive pricing, transparent terms, and timely delivery of orders regardless of volume or complexity.

Types of PCBs We Offer:

- RF PCB: High-frequency circuit printed board

- MC PCB: Metal-based printed circuit

- High Tg PCB: Glass conversion printed circuit

- Heavy copper PCB: Thick copper layer printed circuit

- HDI PCB: High-density board for digital circuits

- FR4 PCB: Based on FR4 material

- Flexible PCB: Foldable printed circuit

- Ceramic PCB: Porcelain-based board with processes including:

- Surface mount

- Component insertion

- Etching, drilling, and plating

- Photolithography and shielding

- Soldering preparation and cutting

- Pressing with adhesive preprog

- Benefits include design reliability, cost reduction, quality control, accuracy, and speed