PCB (Printed Circuit Boards) are commonly used in multiple electronics devices and mobile phones with no exception. Their increasing usage is making PCB more valuable than ever. Whether it’s a mobile, laptop, or other machinery, PCB is more often responsible for its functioning. If there are defects in PCB assembly in mobile, these will cause malfunctions in your phone.

This will cause inconvenience as it will take longer to recall the mobile. Also, it will make the manufacturer spend more resources and time to fix the malfunction. To avoid this hassle, most developers prefer performing PCBA testing on mobile.

What is PCBA test in mobile: What do you need to know about it?

Commonly people don’t know what is PCBA test on mobile. Therefore, here we have a comprehensive guide to let you learn everything about what is PCBA test in mobile below.

So, here we go:

Role of PCBA in mobile phone’s evolution

Over time, technology has brought a lot of advances in how we communicate. Things have changed dramatically from the invention of the first cellular phone in the 1970s to the present mobile phones. Engineers and researchers have been adopting new technologies. They are continuously developing new ways to make mobile phones faster, smaller, and more efficient.

Fortunately, the increased capabilities of PCBA have significantly made mobiles smaller and more powerful. Assembled printed circuit boards allow manufacturers to add more components even in smaller spaces. This allows them to deliver more features in the latest mobile phones.

Moving forward, high-quality PCBA is changing the way how our mobile phones interact with the world.

What is PCBA test in mobile?

PCBA test in mobile is an input-output and electrical conductivity-based testing of PCBA boards. These tests take place with electronic components attached to PCBAs. In the designing phase of PCBs, different test points have a numerical relationship, such as current and voltage.

However, the production and processing system of PCBAs is comparatively complex. This includes multiple important processes such as:

- Component procurement and inspection

- PCB board process

- DIP plug-in

- SMT assembly

- PCBA test, etc.

Therefore, improper Printed Circuit Board Assembly in mobile can lead to faulty equipment or improper working of different components. So, it’s highly important to perform the PCBA test in mobile. You can perform a manual multimeter operation or a professional testing tool to test these points. PCBA tests in mobile help you verify whether the PCBA board is meeting all the design requirements efficiently.

This approach will ensure that your product doesn’t contain any quality problems.

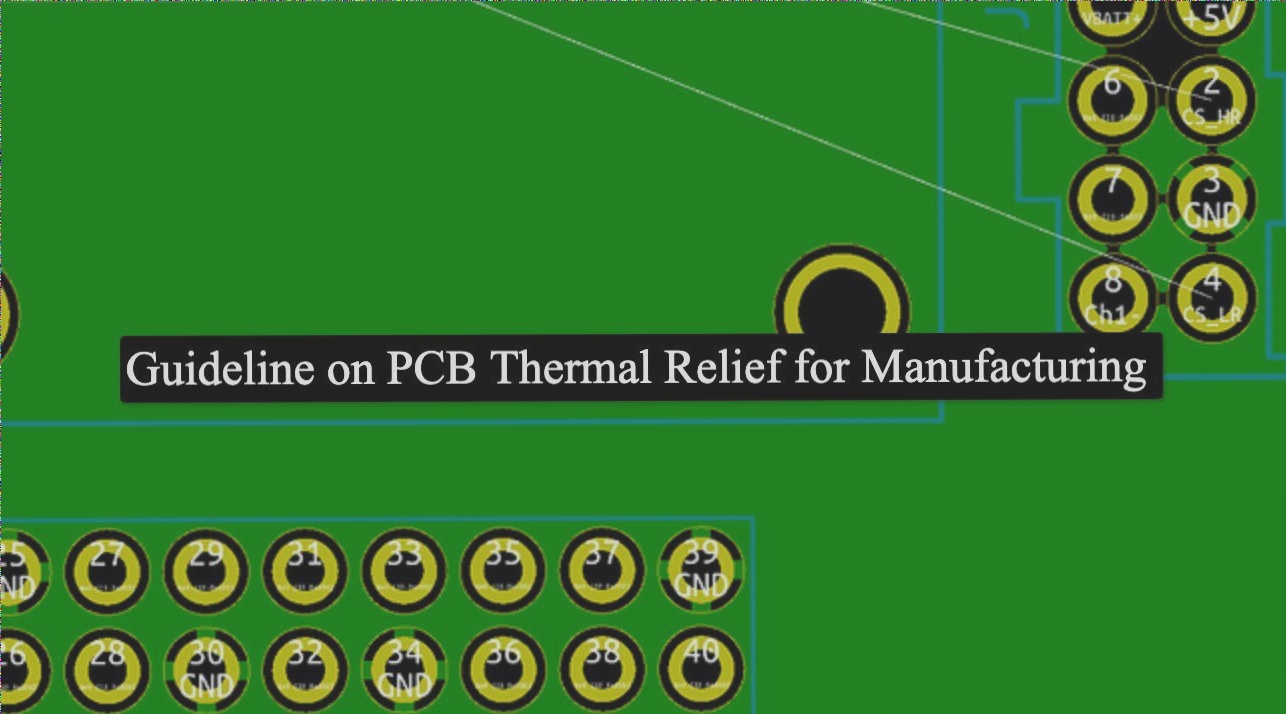

Additionally, PCBA testing is also core to ensuring mobile phone quality. FCT test fixtures have been designed according to the test points of PCBA circuits with the customer’s essential test steps. Testing authorities place PCBA boards on FCT test racks to finish the testing process.

What are the basic tools to use for performing PCBA tests on mobile?

Besides knowing what is PCBA test on mobile, it’s important to learn about tools to perform PCBA tests.

Even though various professional PCBA test tools are available in the market for mobiles. However, to perform a PCBA test on mobile on your own, having the following key tools in hand is necessary. These essential tools include:

- Logic analyzer or oscilloscope

A logic analyzer and oscilloscope are helpful tools to determine voltage changes within an assembled printed circuit board. This tool will let you identify if the printed circuit board assembly is appropriately behaving.

Unfortunately, buying a logic analyzer can be costly, especially for hobby PCBA testers. However, if you want to startup as a PCBA tester for mobiles, you can make this investment for more benefits.

- Multimeter

A multimeter is an amazingly helpful tool to check voltage and measure resistance in a PCBA. A multimeter is a common electronic or electrical measurement tool that you can use to test the whole process.

Using these basic tools can easily help you to test PCBA on mobile. Moreover, you can easily identify if the circuit is properly working or not. Then taking further steps will become easier for you.

Why is the PCBA test important?

PCBA test is a process that mobile manufacturers should perform earlier. Performing a PCBA test after completing the production process only isn’t the right thing to do. Instead, it would be better if mobile manufacturers performed PCBA tests at different production stages to find faults or PCBA errors along the way. It is because a PCBA test performed at the end would be a lot of wasted resources, efforts, and time.

Performing the PCBA test on mobile is important for multiple reasons. After understanding what is PCBA test in mobile, do you want to know why it’s important to perform PCBA testing? Let’s look at the reasons below to determine why it is necessary to perform PCBA testing.

So, the PCBA test in mobile is important to:

Avoid device failure

In PCBA, testing is a key part of manufacturing. Without performing a PCBA test on mobile, there are always risks of experiencing manufacturing faults. Moreover, sometimes PCBA test on mobile can let you identify the defects that may otherwise cause product failure. Such failures can cause serious damage to manufacturers’ reputations and customer relationships. Therefore, it’s highly important to perform the PCBA test in mobile to ensure its proper working.

Optimized device safety

Mobile phones have become the most used devices daily. Therefore, manufacturers need to create mobile phones for optimized safety. Fortunately, proper PCBA testing in mobile can ensure to reduce your manufacturing failure. Additionally, PCBA testing can improve device safety to the optimum level in the best possible way.

So, performing robust PCBA testing at different stages is key before completing mobile manufacturing.

Test individual performance of PCBA components in mobile

Printed circuit board assembly leads to mounting different components to the circuit. PCBA test in mobile is also beneficial to efficiently test each PCBA component’s performance. The PCBA test is a popular technique for quick component-level testing. It will help in ferreting out the faults in mobile PCBA.

PCBA testing professionals generally examine every component of the PCBA circuit to ensure its connectivity. Then they check their performance individually. Often, professionals PCBA testing team use automated test equipment or multimeter tool to perform a thorough defect analysis of the device. The test verifies components’ functioning and determines if each component has soldered rightly on the circuit.

Some more important reasons why the PCBA test in mobile is necessary include:

- Reduced waste

- Reduced number of return products to mobile manufacturers

- Preventing diminish profit margins

- Ensuring customer satisfaction

- Avoiding product liability lawsuit

Overall, these reasons mentioned above make it highly important to perform the PCBA test in mobile.

Things professionals check during a PCBA test.

In a PCBA test, professionals test multiple factors of a mobile. The things tested in a PCBA test more often include:

- Component limitations

PCBA test is also important to determine the component limitations before time. To identify the approximate lifespan of the circuit, it is important to test a PCBA on mobile in detail and keenly. If the PCBA test isn’t performed to determine component limitations, it will risk causing issues in the final functionality of the Printed circuit board assembly.

Testers will focus on checking each component on the circuit board to determine if it is functioning properly. They will also highlight any malfunction immediately to fix it on time.

- Functionality of PCB

Here the tester will analyze how well a PCBA accepts liquid solder for improved solderability. This testing factor is important because it will help you identify the proper functionality of a PCBA circuit on mobile.

The solderability of a PCBA is important to identify. It is because it helps to ensure that all the essential components are firmly attached to the PCBA circuit.

- Conductivity

A PCBA tester will test the copper plating of PCBA on mobile. It helps determine the quality of copper used for the lamination of the board to offer conductivity. They will analyze the tensile strength for ensured conductivity and copper quality.

- Cleanliness factor

This testing solution ensures the resistance level PCBA shows for environmental factors such as corrosion or humidity. It includes PCBA analysis before and after going through different environmental conditions.

- Electric current

The electrical testing feature ensures the PCB conductivity of PCBA in mobile. This technique helps to ensure that the circuit can enable current with minimal leakage.

- Quality of hole wall

Another important component to test in PCBA is hole wall quality. This factor ensures that the hole walls won’t delaminate or crack when a PCBA undergoes further processing. Professionals apply quick cycling and temperature change methods to test hole wall quality. This technique helps in determining how well the PCBA reacts to thermal stress.

Final thoughts

So, that’s all what you need to know about the PCBA test on mobile.

Overall, the PCBA test on mobile is an important way to check all the components attached to the board are working properly. Professionals don’t only perform PCBA tests during mobile repairing. Also, mobile manufacturing companies or brands perform PCBA testing in mobile to ensure a longer lifespan of their devices. PCBA test in mobile offers multiple benefits and helps check board working from different aspects.