The Importance of Silkscreen in PCBs

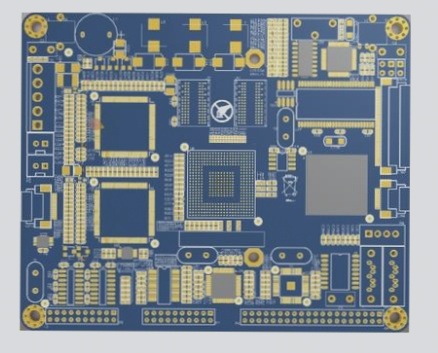

The silkscreen on a Printed Circuit Board (PCB) plays a crucial role in component placement and identification. Initially applied on the component side, it is now commonly seen on the soldering side as well. PCB Silkscreen Printing utilizes epoxy ink in various colors like yellow, white, black, and red.

Although the silkscreen does not impact the functionality of the PCB, it provides vital information such as component designators, polarity indicators, and Pin 1 markings. This information is essential for accurate component placement, especially for components with limited pads.

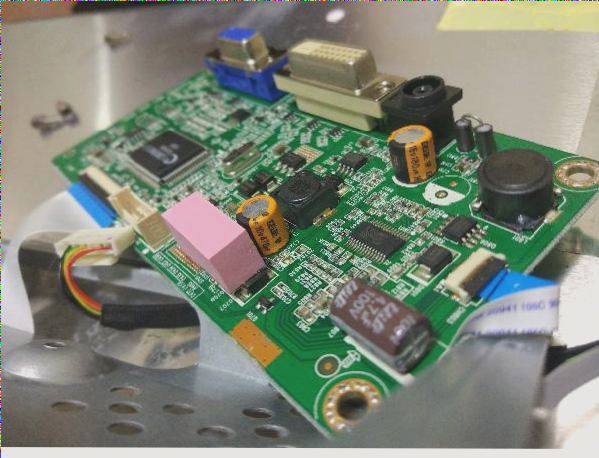

Engineers, technicians, and manufacturers benefit from the PCB silkscreen by having clear markings for measurements during testing and troubleshooting. Different methods are available for silkscreen PCB printing.

When selecting a silkscreen for your PCB, understanding your specific requirements is key. Having a good understanding of PCB silkscreen can be advantageous when working with reputable manufacturers. It is essential to consider factors such as font size, clearance spacing, and color choices when choosing the right silkscreen for your PCB.

For Silkscreen PCBs at WellCircuits PCB assembly, direct communication with trusted contacts is recommended. Despite having international headquarters, clear communication with vendors through phone or online channels ensures transparency in product specifications. Collaboration between the Contract Manufacturer (CM), PCB assembly technicians, and experienced end-users is crucial for successful product testing and issue resolution.