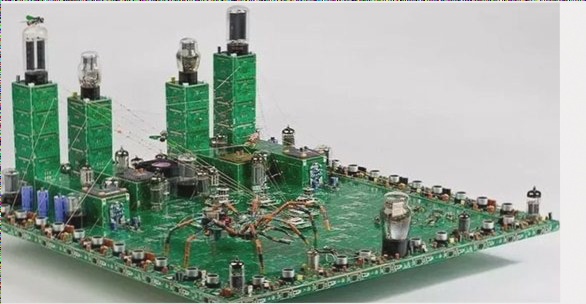

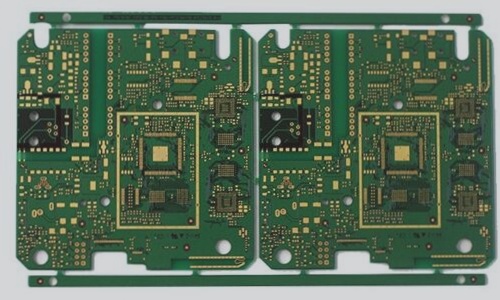

1. As a PCB expert, I would like to discuss the topic of blank PCBs. Also known as bare PCBs or empty PCBs, these electronic boards are made by laminating epoxy glass fiber, copper foil, and PCB ink.

2. A blank PCB is essentially an empty circuit board without any components installed to create a functional circuit board. In some cases, these boards are referred to as “copper clad” circuit boards due to the layer of copper coating around the board.

Blank PCB boards consist of a non-conductive prepreg or polymer layer, as well as solder film between the substrate, copper wire, and copper wire. Copper wires in different layers are connected by copper filled holes.

These boards are commonly used to create custom passive filter circuits and are designed to be installed in electronic component casings to provide a layout with three holes in one group, or PCBs with multiple sets of series components. Each group of components has five sizes and parallel wound components.

Types of blank printed circuit boards are as follows:

1. FR-4

The FR4 PCB is the most common blank PCB, with FR4 representing level 4 flame retardancy. This type of PCB is actually an epoxy glass fiber PCB with a fourth level flame retardant rating. The pre impregnated layer between the copper layers is also epoxy glass fiber, but it is semi cured. FR4 blank PCBs are easy to manufacture and cheaper than other PCBs with the same number of layers and circuit complexity.

2. Metal core PCB

Metal core PCBs include aluminum core PCBs and copper core PCBs. These substrates have much better thermal conductivity than FR4 cores, and are mainly used for LED lighting and other power applications.

3. Rigid-Flex PCB

Flexible PCBs and rigid-flex PCBs are PI or PET-based blank PCBs that can bend. Rigid-flex PCBs are special flexible PCBs because their flex section is laminated with FR4 PCB layers.

4. High Frequency PCB

A high-frequency PCB, also known as a high-speed and RF microwave PCB, is a PTFE-based blank PCB that transmits and receives high-frequency signals. These can be used for antennas, radars, anti-collision systems, GPS, smartphones, missile systems, etc.

In order to design a blank PCB, it is important to adhere to certain principles when designing PCB wiring. These include separating analog signals from clock signals, maintaining a line angle greater than 135°, keeping the same line width in the same network, and keeping the lines as short as possible. After completing the PCB design, it is necessary to ensure that the PCB has uniform impedance, low electromagnetic interference, and manufacturability.

Ultimately, the main function of a blank PCB board is to provide physical support for the circuit board, as well as the installation location and connection points of components.

2. A blank PCB is essentially an empty circuit board without any components installed to create a functional circuit board. In some cases, these boards are referred to as “copper clad” circuit boards due to the layer of copper coating around the board.

Blank PCB boards consist of a non-conductive prepreg or polymer layer, as well as solder film between the substrate, copper wire, and copper wire. Copper wires in different layers are connected by copper filled holes.

These boards are commonly used to create custom passive filter circuits and are designed to be installed in electronic component casings to provide a layout with three holes in one group, or PCBs with multiple sets of series components. Each group of components has five sizes and parallel wound components.

Types of blank printed circuit boards are as follows:

1. FR-4

The FR4 PCB is the most common blank PCB, with FR4 representing level 4 flame retardancy. This type of PCB is actually an epoxy glass fiber PCB with a fourth level flame retardant rating. The pre impregnated layer between the copper layers is also epoxy glass fiber, but it is semi cured. FR4 blank PCBs are easy to manufacture and cheaper than other PCBs with the same number of layers and circuit complexity.

2. Metal core PCB

Metal core PCBs include aluminum core PCBs and copper core PCBs. These substrates have much better thermal conductivity than FR4 cores, and are mainly used for LED lighting and other power applications.

3. Rigid-Flex PCB

Flexible PCBs and rigid-flex PCBs are PI or PET-based blank PCBs that can bend. Rigid-flex PCBs are special flexible PCBs because their flex section is laminated with FR4 PCB layers.

4. High Frequency PCB

A high-frequency PCB, also known as a high-speed and RF microwave PCB, is a PTFE-based blank PCB that transmits and receives high-frequency signals. These can be used for antennas, radars, anti-collision systems, GPS, smartphones, missile systems, etc.

In order to design a blank PCB, it is important to adhere to certain principles when designing PCB wiring. These include separating analog signals from clock signals, maintaining a line angle greater than 135°, keeping the same line width in the same network, and keeping the lines as short as possible. After completing the PCB design, it is necessary to ensure that the PCB has uniform impedance, low electromagnetic interference, and manufacturability.

Ultimately, the main function of a blank PCB board is to provide physical support for the circuit board, as well as the installation location and connection points of components.