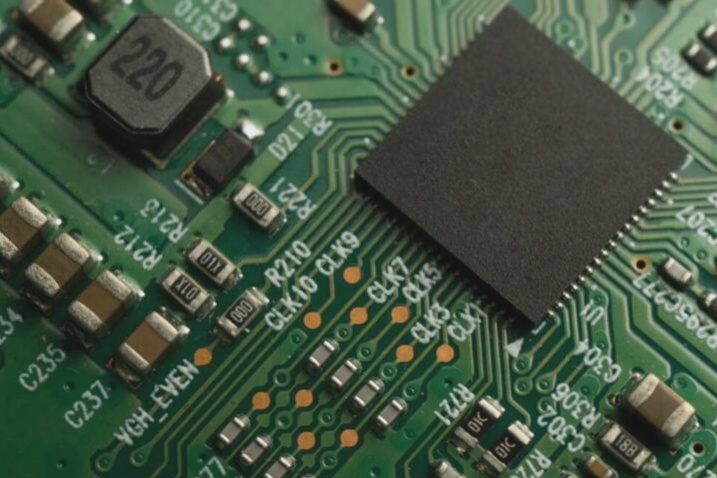

The Significance of Copper-Clad Laminate (CCL PCB) in PCB Manufacturing

- Copper-clad laminate (CCL) is a vital core material in PCB manufacturing, playing a crucial role in the functionality of PCBs.

- A circuit board consists of a copper-clad plate composed of a substrate, copper foil, and adhesive.

- CCL PCB serves as interconnections, insulation, and support for circuit boards, influencing signal transmission speed and energy loss.

Raw Materials for CCL PCB Manufacturing

- Resin: Phenolic and epoxy resins are commonly used, offering excellent bonding and electrical properties.

- Impregnated Paper: Cotton velvet paper and wood pulp paper are utilized for their resin permeability and mechanical strength.

- Alkali-Free Glass Cloth: Used as a reinforcing material for glass cloth-based laminates, suitable for high-frequency applications.

- Copper Foil: Electrolytic copper foil is widely preferred in the production of CCL PCB.

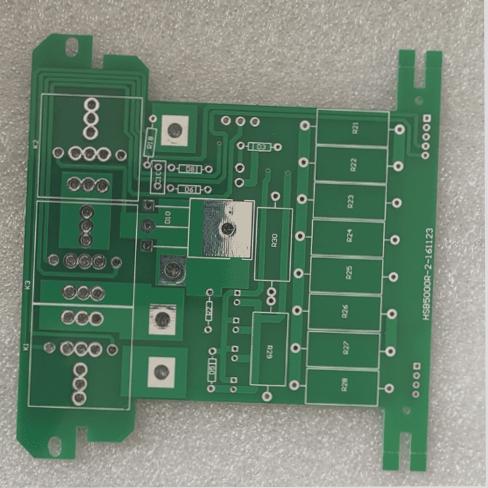

Classification of CCL PCB Boards

Copper-clad plates are categorized into rigid, flexible, and special materials, each serving different application needs:

- Rigid: Ideal for communication equipment, household appliances, and electronic toys.

- Flexible: Commonly used in automotive electronics, mobile phones, and laptops for easy component assembly.

Evolution of CCL PCB

CCL PCB has evolved from being a basic material for supporting electronic components to directly manufacturing printed electronic components. It is indispensable in various electronic products, ranging from aviation and aerospace to household appliances and high-end electronic toys.

The Significance of High-Tech Materials in PCB Manufacturing

In the realm of electronic products, the demand for smaller, lighter, and thinner devices has driven significant advancements in the manufacturing of printed circuit boards. As a result, the production of PCBs is closely intertwined with various cutting-edge technologies. At the core of this process lies the critical material known as CCL PCB material, which plays a pivotal role in ensuring that PCBs meet the stringent requirements of modern high-tech applications.