Single-Sided PCB: Overview and Applications

Introduction to Single-Sided PCB

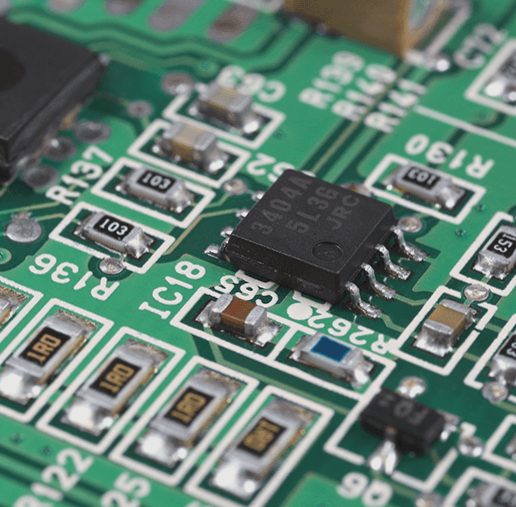

A single-sided PCB is a type of printed circuit board that has wiring on only one side, with the other side covered with substrate or insulating ink. This design makes the board transparent under strong light, except for specific boards with special process requirements. The side with lines on the transverse section contains copper foil.

Benefits and Usage of Single-Sided PCB

A single-sided PCB consists of a single circuit and electronic components, making it suitable for simple electronic products like calculators and toys. It is often the first type of circuit board beginners work with due to its lower costs and production process requirements. However, its design limitations restrict its application in more complex products.

Key Features of Single-Sided PCB

- Etched copper-coated boards

- Consists of a plate base and copper foil

- Provides mechanical support for electronic components

- Enables electrical connection and insulation

Applications of Single-Sided PCB

Single-sided PCBs find applications in various industries, including LCD, FPC, chemical, and household appliances. They are commonly used in radios, heaters, printers, vending machines, and electronic components.

Types of Materials Used

1. Phenolic Paper Substrate: Also known as cardboard, this type of substrate is cost-effective and flame-retardant, suitable for basic electronic applications.

2. Epoxy Fiberglass Cloth Substrate (FR4): Utilizing epoxy resin and fiberglass cloth, this substrate is ideal for double-sided PCBs due to its high working temperature and environmental resilience.

Composite Substrate in PCB Manufacturing

Composite substrate, also known as powder board or 22F in some regions of China, primarily consists of CEM-1 and CEM-3 composite copper-clad laminates. CEM-1 is crafted from wood pulp fiber paper or cotton pulp fiber paper as the core material reinforcement, with glass fiber cloth as the surface reinforcement, all immersed in flame retardant epoxy resin. On the other hand, CEM-3 is composed of glass fiber paper as the core material reinforcement and glass fiber cloth as the surface reinforcement, both immersed in flame retardant epoxy resin. These two varieties are the most prevalent in the realm of composite-based copper-clad plates, offering a cost-effective alternative to the FR4 type plate.

Key Features of Single-Sided PCBs

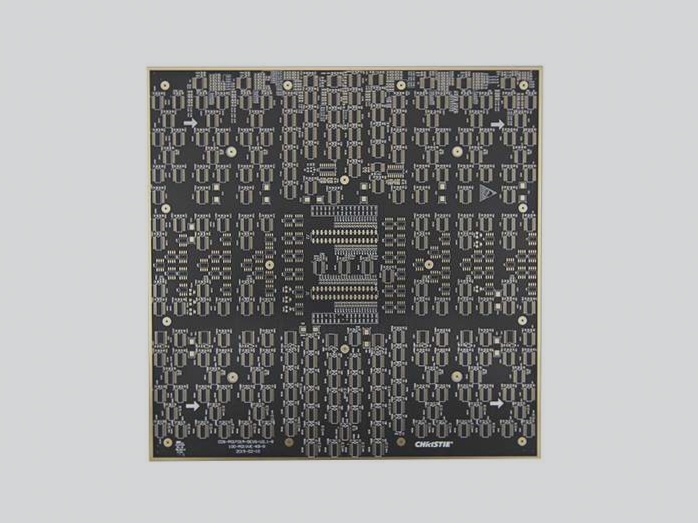

A single-sided PCB represents the fundamental form of PCB design, with components concentrated on one side and wiring on the other. The unidirectional wiring characteristic gives rise to the term “single panel” for this type of PCB.

- Enhanced repeatability and consistency in graphics reduce errors in wiring and assembly, thereby saving time on equipment maintenance, debugging, and inspection.

- Standardized design promotes interchangeability and ease of use.

- High wiring density, compact size, and lightweight nature contribute to the electronic equipment’s miniaturization.

- Facilitates mechanized and automated production, enhancing labor productivity and diminishing the overall cost of electronic devices.