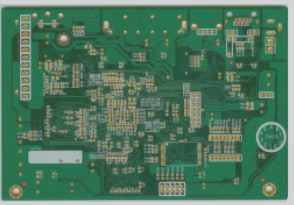

The Importance of Testing in PCB Copying Process

In the process of PCB copying, especially for high-precision circuit boards, testing plays a crucial role. Testing is essential to ensure that the replicated PCBs meet the required standards. While flying probe testers and test rack testing are commonly used tools for circuit board duplication, another electronic testing device known as AOI (Automated Optical Inspection) has gained popularity in recent years.

Automated Optical Inspection (AOI)

AOI is a modern testing technology that utilizes a camera to scan the PCB during automated inspection. The captured images are compared with predefined parameters stored in a database. The system then identifies defects on the copied PCB and highlights them for technicians to address and repair.

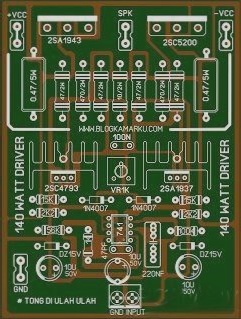

Implementation Objectives of AOI

- End Quality: AOI is placed at the end of the production line to monitor the final condition of the product, ensuring high quality especially in scenarios with well-defined production issues, high product variety, and critical factors like quantity and speed.

- Process Tracking: AOI is used to monitor the production process itself, providing detailed defect classification and component placement information. This objective is crucial for product reliability, low-mix high-volume manufacturing, and stable component supply.

Key Inspection Stages

There are three key inspection stages where AOI plays a vital role:

- After solder paste printing: Inspection at this stage is essential for process monitoring and characterization, detecting common printing defects such as insufficient solder, excess solder, poor alignment, and solder bridges.

- Before reflow soldering: This stage helps in detecting defects from solder paste printing and component placement, providing insights for calibration and adjustment of placement machines.

- After reflow soldering: Post-reflow inspection is crucial as it identifies assembly errors originating from solder paste printing, component placement, and the reflow process.

If you are looking for PCB manufacturing services, feel free to contact us.