In the traditional PCB circuit board design, boards typically use copper clad/epoxy glass cloth substrates or phenolic resin glass cloth substrates, with a small amount of paper-based copper clad boards. These materials offer good electrical and processing properties, but have poor thermal conductivity. With the prevalence of surface mount components like QFP and BGA in modern PCB board design, the heat generated by components is transferred to the PCB board in large quantities. Therefore, the most effective way to address heat dissipation issues is to improve the ability of the PCB board to dissipate heat that is in direct contact with the heating elements, whether it is being transmitted or emitted through the board.

When a few components on the PCB generate a significant amount of heat, a heat sink or heat pipe can be added to these components. If temperatures cannot be reduced sufficiently, a heat sink with a fan may be necessary. In cases where the number of heating components on the PCB board is high, a large heat dissipation cover can be utilized. This cover can be secured onto the surface of the components as a whole, ensuring contact with each component on the PCB board for effective heat dissipation. For professional computers used in video and animation production, water cooling may even be required for efficient cooling.

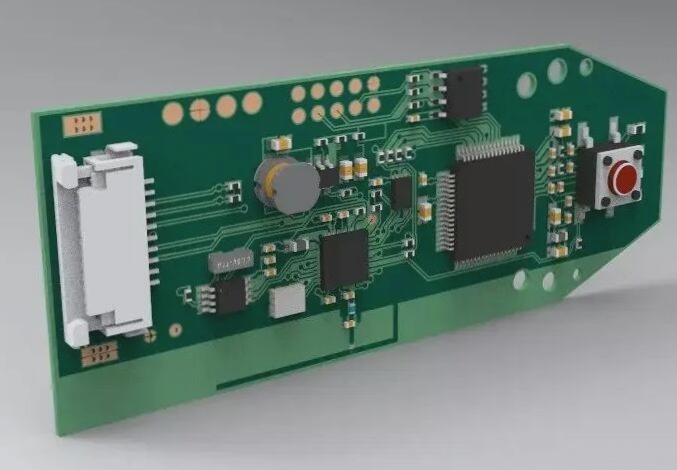

WellCircuits Limited is a manufacturer specializing in the production of high-precision double-sided, multi-layer, and impedance-controlled circuit boards. Their products include blind buried vias, thick copper boards, and various types of circuit boards such as HDI, backplanes, rigid-flex combinations, buried capacitance and resistance, Golden Finger boards, among others. These products cater to the diverse needs of customers across different industries.

In PCB board design, the heat dissipation system includes cooling methods and the selection of heat dissipation components, as well as consideration of the coefficient of thermal expansion. Currently, common methods for PCB heat dissipation include utilizing the PCB itself for heat dissipation, as well as adding heat sinks and heat conduction boards to the PCB.