Understanding Test Points on FR4 PCBs

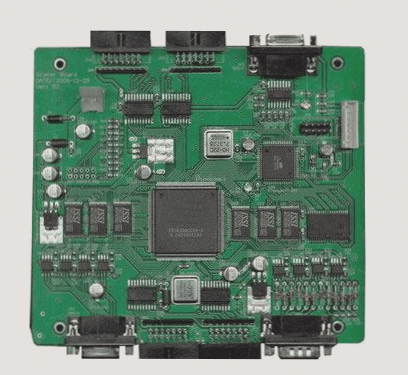

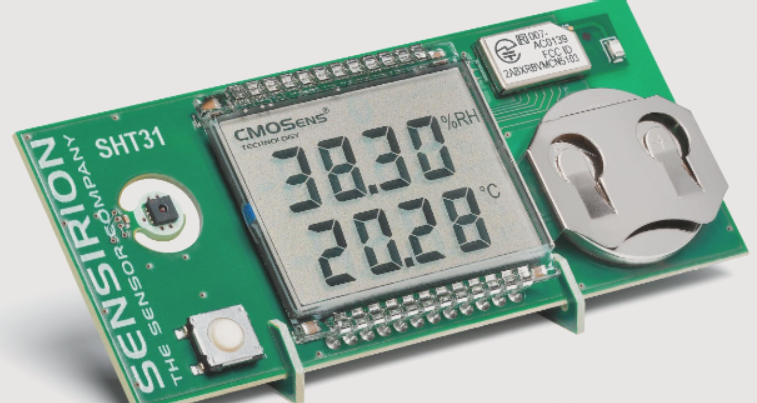

When it comes to electronics and FR4 PCBs, the concept of test points plays a crucial role in ensuring the quality and functionality of circuit boards. Test points are small circular points strategically placed on circuit boards to facilitate testing of components.

The Purpose of Test Points

The main objective of test points is to verify if the components on the circuit board meet the required specifications and solderability standards. By using test points, engineers can efficiently test for faulty resistance, capacitance, inductance, and IC circuits without directly contacting the electronic parts, thus preventing potential damage.

Utilizing In-Circuit-Test (ICT)

In a mass production setting, the In-Circuit-Test (ICT) automatic test machine is employed to streamline the testing process. This machine utilizes multiple probes, also known as “Bed-Of-Nails” fixtures, to simultaneously make contact with all the parts and circuits on the board that require measurement. Through program control, the characteristics of electronic parts are sequentially measured, ensuring efficient and accurate testing.

Evolution of Test Points

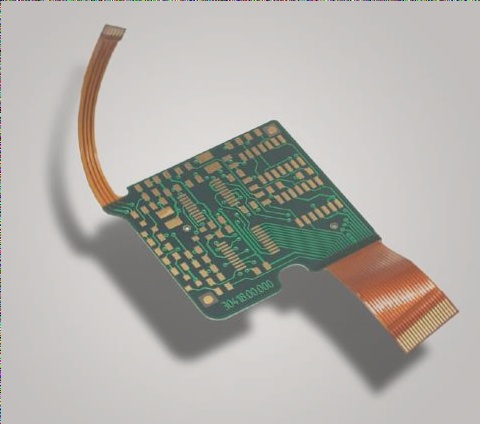

In the early days of circuit board technology, traditional plug-in (DIP) components served as test points. However, with the advancement of SMT technology, dedicated test points became essential to protect fragile components from probe pressure and ensure reliable testing results.

Challenges and Innovations

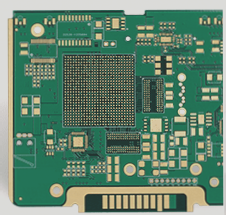

As technology progresses and circuit boards become smaller, the challenge of accommodating test points while maintaining efficient design and manufacturing processes arises. Innovations such as Net test, Test Jet, Boundary Scan, and JTAG are being explored to reduce the reliance on traditional test points and adapt to the evolving landscape of PCB testing.

Future Considerations

Manufacturers are continuously refining testing methods to address the limitations of traditional test points. Alternative techniques like AOI and X-Ray are being considered, but ICT remains a cornerstone in ensuring comprehensive testing. Collaboration with manufacturers is key to optimizing test point placement and maximizing testing efficiency.