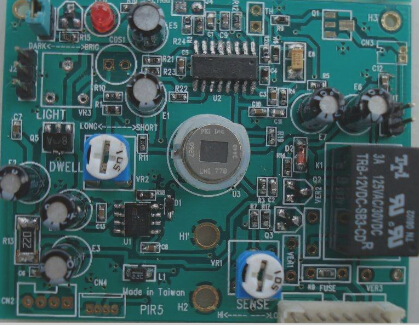

I believe many of us still recall when PCBs were central to the product design process.

This PCB-centric design approach involves the PCB, machinery, and supply chain teams working independently, integrating their results only at the prototyping stage. If something is unsuitable or cost requirements aren’t met, rework is necessary, which can be quite expensive.

This method has been prevalent for many years. However, product structures are evolving. In 2014, a notable shift towards a product-centric PCB design approach occurred, and further adoption of this method is anticipated in 2015.

Let’s examine the system-on-chip (SoC) ecosystem and product packaging. SoC has significantly influenced the hardware design process.

By integrating numerous functions onto a single SoC chip, along with the characteristics of specific applications, engineers can utilize reference designs for their research and development efforts. Many current products leverage SoC reference designs and build differentiated designs upon them.

Conversely, product packaging and aesthetics have become crucial competitive factors, resulting in increasingly complex shapes and angles.

Consumers are seeking products that are smaller and more visually appealing. This necessitates that smaller PCBs fit into more compact enclosures, thereby reducing the likelihood of failure.

While SoC-based reference designs simplify the hardware design process, these designs still need to be housed within an innovative shell, demanding closer coordination and collaboration across various design criteria.

For instance, a particular enclosure may dictate the use of two PCB boards instead of a single-board design. In this scenario, PCB planning truly embodies the essence of product-centric design.

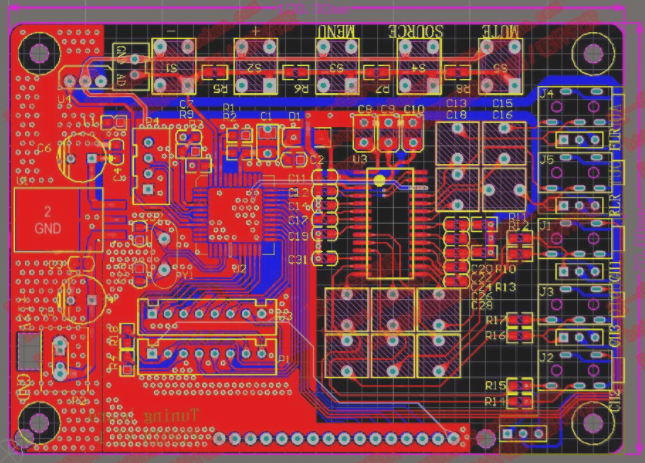

1. This presents a significant challenge to the current PCB 2D design tools. The limitations of today’s PCB tools are evident in several areas: insufficient visualization of product-level design, lack of multi-board support, limited or absent MCAD collaborative design capabilities, and inadequate support for parallel design or for conducting cost and weight target analyses.

2. The principle of multi-design and the collaborative product-centric design process represent a fundamentally different approach. The constantly evolving competitive landscape, combined with the PCB-centric approach, is unable to keep pace with this new methodology. At this juncture, a more collaborative and adaptive design process is essential.

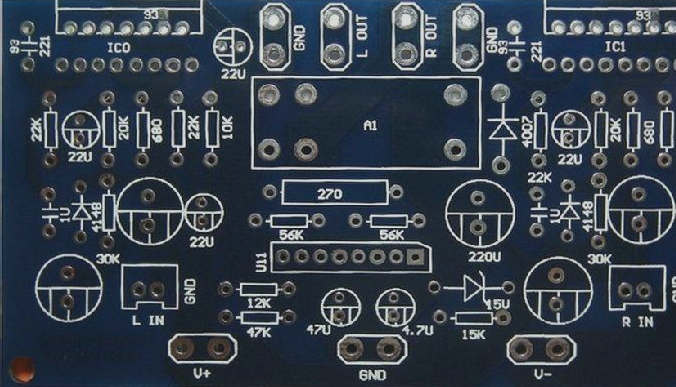

3. A crucial aspect of product-centric design is its architecture verification, which enables companies to respond more swiftly to emerging and complex product requirements. Architecture serves as the link between product requirements and detailed design; this is where a product can gain a competitive edge, provided it has a well-structured architecture.

4. Before moving on to detailed design, it is important to first analyze whether the proposed product architecture meets multiple design criteria.

5. The factors that need to be assessed include: size, weight, cost, shape, and functionality of the new product, the number of PCBs required, and their compatibility with the designed enclosure.

6. Additional reasons PCB manufacturers can achieve cost and time efficiencies by adopting a product-centric design approach include:

7. Concurrent execution of 2D/3D multi-board design planning and implementation;

8. Importing/exporting STEP models that have been verified for redundancy and compatibility;

9. Modular design (design reuse);

10. Enhanced communication and interaction within the supply chain.

11. These functionalities support the company’s product-level considerations and can maximize their competitive advantages.

If you have any PCB manufacturing needs, please do not hesitate to contact me.Contact me