Advantages and Factors Affecting the Number of Layers in Multilayer PCBs

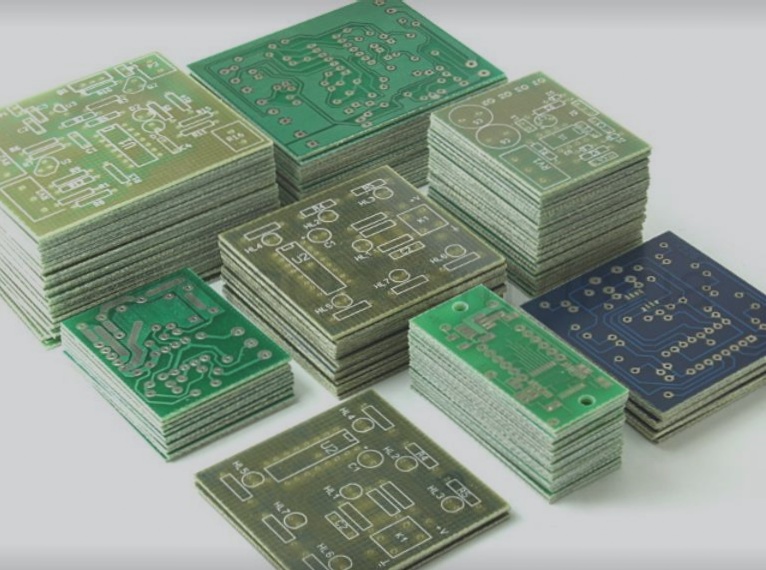

Multilayer PCB, or printed circuit board, is designed with multiple conductive layers on a single substrate to meet specific requirements, enabling high-speed signal transmission and efficient circuit processing.

Factors Influencing the Number of Layers:

- Purpose: Consider the complexity of the electronic device where the PCB will be used.

- Signal Type: Different signal types require varying layers for transmission.

- Through-Hole Type: Selection of through-hole affects the need for internal layers.

- Signal Layer and Pin Density: Pin density influences the number of layers required.

Main Reasons for Multilayer PCB Design:

- Signal Integrity: Enhances signal integrity and reduces interference.

- Space Utilization: Maximizes PCB space for compact layouts.

- Power Layering: Separates power supply and ground for stability.

- Thermal Management: Improves heat dissipation and device stability.

Advantages of Multilayer PCBs:

- Reduced Impedance: Shortened wire length lowers circuit impedance.

- Efficient Energy Transmission: Simultaneous transmission of multiple signals enhances power efficiency.

- Weight Reduction: Compact design leads to lighter equipment.

The number of layers in a PCB impacts performance, manufacturing complexity, and cost. Factors such as circuit board complexity, thickness, and cost should be considered to achieve optimal results. WellCircuits offers PCB support up to 108 layers, providing solutions for various electronic applications.