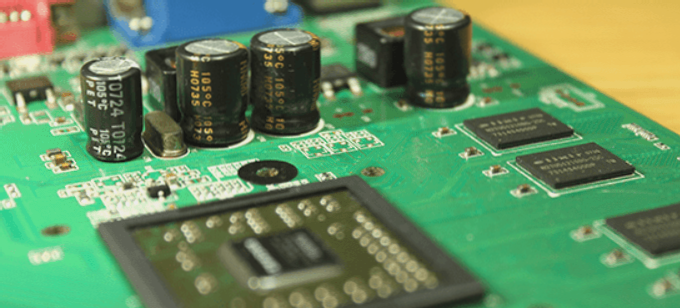

PCB is an abbreviation of printed circuit board which refers to an electric board that has certain electronic components soldered onto them. Since the world is moving in from mechanics to electricity – everything that we use these days, including our phones and computers, has some kind of electric board installed in them. You can buy these boards from a store or make them yourself (using the right material and steps). Because if you mess up one step, it can render the end product useless.

Where are printed circuit boards used?

Printed circuit boards are installed in almost every electrical device we own these days—for example, our computers, laptops, phones, and tablets. You can say that the printed circuit boards act as electricity agents for these devices – providing the devices with the power to run.

On top of this, the printed circuit board is also used as a deck to organize the electronic elements for the devices. Similarly, PCB is also used in several industrial projects that involve electrical devices.

There are four types of PCB’s:

- Single-sided

- Double-sided

- Multi-layered

- Fabricated PCB

What is the PCB fabrication process?

PCB fabrication process issued to create electrical boards that serve as a foundation for different printed circuit board assembly.

However, it may seem like a simple process, but it takes a lot of effort and care to get the PCB fabrication right. Therefore, if you are getting your PCB fabricated, you should hire a contractor who knows how to take care of your circuit because a small error can damage the entire board rendering the end product useless.

Similarly, there is a clear difference between PCB fabrication and the assembly process. When we talk about PCB fabrication, it means that we are transcribing a board design onto a physical structure of another board. However, when you talk about the PCB assembly process, it means that you’re just placing all the compliments on a board to make it functional.

So when you fabricate something, you’re just making a duplicate; however, when you assemble a PCB, you’re using your brain and understanding to pull it off.

2 Things that you need to do before PCB Fabrication

PCB fabrication takes a lot of effort to get right. Therefore you have to follow some steps before the actual procedure to make sure that you’re not ruining your product in the process.

You have to ensure that the initial design is complete and you know what you’re going to do because if you mess up a single component and it is not synchronized with the board, then it can lead to a Bad board bill which will render the end product as useless.

Review Everything

Before fabricating the PCB, you have to complete an engineering review for all the circuits to make sure that they are going to be placed in certain positions. However, you cannot sit and try out which to wax with when you are fabricating PCB. So you will have to do all of this beforehand. You can watch some videos online to get the procedure right.

Similarly, you have to work out a synchronized Layout of all the databases so that you know what you’re working with while fabricating the PCB.

Go over rules of PCB Fabrication

Once you know how everything works, you should also take time out to check all the PCB design rules and constraints that you need to follow to get the process right. Similarly, you should also know what materials you are going to use in the process. So once you start, you don’t have to go out again to get another material. It will save you time and effort.

PCB FABRICATION PROCESS – STEP BY STEP GUIDE

The PCB fabrication process begins with a multi-layered print so I can board and a direct laser imaging which is applied to the areas that will become traces pads and a metal ground of the printed circuit board.

Once you are done with that, here are some steps that you need to follow:

- You will have to apply a dry film on a copper laminate board. Once that is done, you need to do direct laser imaging that will expose all the parts of the board to light in the shape of the busy bee button that you need to follow.

- Moving on, when you will laser direct the image, all the unexposed parts of the board will develop, and the remaining film will be left as an etch on the barrier of the board. Remove it with your hands.

- After you are done with all the steps, use an automated optical inspection that will detect all the layers for any defects before laminating the board together. Ensure that you collect any potential short or opens at this stage because after the board is nominated, you will not be able to correct them.

Lamination Process

Ensure that there are no errors in the circuit. The next step is to oxide and laminate the board. All the layers that are etched will be treated with a chemical called oxide, which will be applied onto the inner layers of the printed so I can board so that the strength of the bond is improved.

Similarly, you will have to apply pre-preg and copper foil layers and use heat and hydraulic press to join these alternating layers. When the hydraulic press is applied, the fiberglass material containing the exposy resin will melt from all the heat and pressure of the lamination and form a bonding of the layers called a PCB sandwich.

Drilling of holes

Once the layering is done, you need to drill holes on the printed circuit board so that it can send signals from one left to another. The holes are drilled or lasered into the circuit and connected onto a board to send the signals properly.

The drilling is different for the type of via being used. However, it is done using a stack of two or four panels simultaneously. When the drilling is done, the end result will be five mils larger than the end product because the holes that are drilled onto the board or plated with copper to hell send electrical signals. The copper well makes the circuit board thicker and heavier.

Copper deposition

When the holes are drilled onto the surface, the excess resin and the debris is cleaned using a chemical. When the excess debris is removed, the board exposes a thin layer of copper coating which is deposited on all the exposed parts of the electric panel. This creates a metallic base for all the electroplating process that needs to be carried out in order to send signals from one connection to another.

Electroplating of the board

After the excess debris is removed, we will use a conductive button to place the panel into a copper plating bath that contains sulfuric acid and copper sulfate. Moving on, you will add an electrical current into the copper sulfate solution, which will be deposited onto the conductive surface of the PCB.

After the plating process, you will have to remove the dry parts, which will leave the dressing and pads on the plate.

Finishing everything

Before you assemble the PCB into its final look, the board will have to be protected with the soldiering mask using a similar kind of UV exposure that is found on the photoresist stage.

Once the soldering is done, the circuit board will have a distinctive green color. The soldering is done with a thin layer of polymer which will protect all the cop addresses on the board from getting ruined over time. However, you can use any color other than green, but experts say that green color is better as it is effective in the inspection as it has high contrast and critical visibility to trace any problems.

Once the soldering is done, you have to use a protective layer that will cover all the components of the PCB to ensure that they remain enclosed.

Once the coating is done, you have to assemble the PCB board into its complete form and test everything so that you know that it does not have any errors. You will have to test each second before shipping them.

Key Takeaways:

Printed circuit boards are used in a lot of machines these days. You can find them on your computers, mobile phones, and televisions. There are many ways to assemble PCB. However, it takes a lot of effort to get it right. Therefore, people use a fabrication process to duplicate boards for their use.

The fabrication process takes some level of expertise, but once you get your hands on them, you can do it easily. Once you place the circuits into that position and laminate them for additional protection, use a trial Nero process to test out all the circuits to ensure they work properly.

Looking for a PCBA supplier?

Shenzhen WellCircuits Technology Co., Ltd. was established in 1999. We are focus on the high-quality PCBA order demand of “Multiple varieties, medium and small batch, and short delivery period. As a one-stop PCBA manufacturer, we provide the services of PCB design, PCB manufacturing, PCB assembly,DFMA service, component purchasing and test assembly. If you are looking for a professional PCB manufacturer, please do not hesitate to contact us.