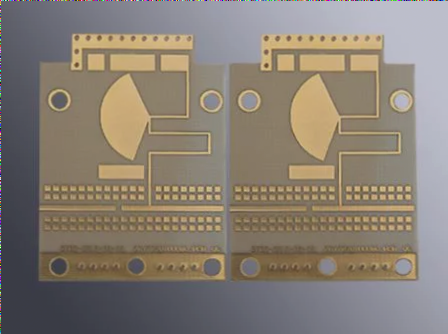

1. PCB board thickness usually refers to the overall thickness of a PCB, including circuit layers, dielectric layers, and copper-clad layers.

2. The thickness of a PCB is usually expressed in millimeters (mm), and common thicknesses include 0.6mm, 1.0mm, 1.6mm, 2.0mm, 2.4mm, and so on.

3. When designing a PCB, it is necessary to choose the appropriate board thickness based on actual needs to ensure the performance and reliability of the PCB.

4. As a PCB expert, it is crucial to consider the impact of board thickness on the electrical and mechanical properties of the PCB.

5. Thicker PCBs can provide better rigidity and heat dissipation, but may also result in higher manufacturing costs.

6. On the other hand, thinner PCBs are lighter and more cost-effective, but may be more susceptible to bending or warping.

7. In high-frequency applications, the thickness of the PCB can also affect signal integrity and impedance control.

8. Therefore, PCB designers should carefully evaluate the specific requirements of the application and select the most suitable board thickness accordingly.

9. Additionally, the selection of board thickness should also take into account the compatibility with other components and the manufacturability of the PCB.

10. Overall, a well-informed decision on PCB board thickness is essential for ensuring the overall functionality and performance of the final PCB product.

PCB board thickness

1. Conventional thickness: 1.0mm, 1.6mm, 2.0mm

These thicknesses are usually used for general applications, such as consumer electronics, smart homes, industrial controls, and so on. These applications do not require particularly high mechanical strength or electrical conductivity, so conventional-thickness PCBs can be used.

2. Ultra-thin plate thickness: 0.4mm, 0.6mm

The thickness of these ultra-thin plates is usually used for lightweight and miniaturized electronic products, such as smartwatches, smartglasses, and smart wearable devices. These products require very lightweight PCBs, so using ultra-thin PCB board thickness can meet the demand.

3. High-strength plate thickness: 2.4mm, 3.0mm

These high-strength plate thicknesses are typically used for some industrial and military applications, such as aerospace, railway transportation, military equipment, and so on. These applications require PCBs to have very high mechanical strength and durability, so using PCBs with high-strength board thickness can meet the requirements.

In summary, the selection of PCB board thickness needs to be determined based on specific application requirements. When selecting the thickness of a PCB board, multiple factors such as mechanical strength, conductivity, and cost need to be considered to ensure the performance and reliability of the PCB. At the same time, it is also necessary to pay attention to the thickness limit of the PCB board to ensure that the designed PCB can be manufactured and assembled.

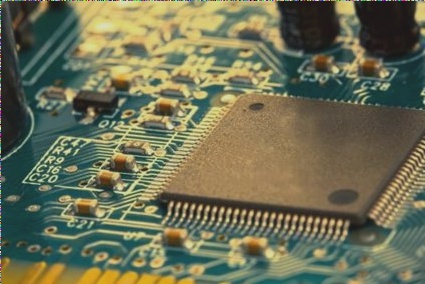

Factors affecting PCB thickness

1. Copper thickness

The total thickness of a PCB is affected by the thickness of the copper layer it contains. A thicker copper layer, such as 2 ounces or 3 ounces of copper, contributes more to the total thickness than a thinner copper layer. The thickness of the copper layer used is determined by the current that the circuit board needs to pass through.

2. Substrate material

The choice of substrate will significantly affect PCB board thickness. Different materials have different thicknesses. For example, compared to rigid PCB substrates, flexible printed circuit boards often have thinner substrates. Common substrate materials such as FR-4 have standard thicknesses, but special materials may have unique thickness characteristics.

3. Number of PCB layers

For single-layer PCBs, their thickness is smaller compared to multi-layer printed circuit boards. The standard threshold for PCB thickness usually accommodates 2-6 layers of PCB. However, for layers of 8 or more, the thickness may not be within the standard range. Each additional layer will increase the total thickness of the PCB.

4. Signal type

The thickness of a PCB is influenced by the type of signal it carries. For example, PCBs carrying high-power signals require thicker copper layers and wider wiring, which are much thicker than circuit boards operating in low-power environments. On the other hand, high-density boards with complex signals typically use laser micropores, fine marks, and thin high-performance materials, making them traditionally thinner than other types of boards.

5. Type of through-hole

PCB via playback is crucial for wiring across different layers of the circuit board, achieving a more compact and efficient design. Multiple types of vias can be used for different applications, including through, micropores, blind holes, and through burial.

The selection and density of vias used in PCB design will affect the required board thickness. For example, using micropores on thinner PCB boards is feasible because they are smaller in size and very suitable for high-density connections. Understanding the characteristics and limitations of different through-hole types is crucial for determining the appropriate PCB board thickness for a given design.

6. Operating conditions

Operating conditions are another important factor affecting PCB board thickness. For example, under challenging operating conditions, such as harsh environments, thin or flexible plates may not be the most suitable choice. Similarly, when exposed to high currents, thicker copper traces have poor thermal stability, making them less suitable for temperature changes or high current environments.

The primary consideration when customizing PCB thickness

1) Weight: Thicker plates are usually better than thinner plates because thinner plates are often more brittle and prone to breakage unless specific applications require thin plates.

2) Flexibility: Compared to thick plates, thin plates provide greater flexibility, but they are also more prone to cracking. Thick plates, on the other hand, are less flexible but heavier.

3) Space limitations: Device size and available space to accommodate PCBs can affect the selection of board thickness. Larger devices can accommodate thicker circuit boards, while smaller devices require smaller circuit boards.

4) Connectors and components: The types of connectors and components used in PCB design may have specific thickness requirements to consider.

5) Impedance: The thickness of a PCB board is directly related to the thickness of the dielectric material used, which plays an important role in achieving appropriate impedance characteristics. Optimal signal integrity and performance can be achieved in a PCB by ensuring that the board thickness matches the expected impedance.

PCB board thickness is one of the important factors to consider when manufacturing printed circuit boards, as it affects conductivity, resistance, and PCB performance. In the PCB industry, there is no unified standard for PCB board thickness, but some thicknesses are preferred and commonly used by many manufacturers.

2. The thickness of a PCB is usually expressed in millimeters (mm), and common thicknesses include 0.6mm, 1.0mm, 1.6mm, 2.0mm, 2.4mm, and so on.

3. When designing a PCB, it is necessary to choose the appropriate board thickness based on actual needs to ensure the performance and reliability of the PCB.

4. As a PCB expert, it is crucial to consider the impact of board thickness on the electrical and mechanical properties of the PCB.

5. Thicker PCBs can provide better rigidity and heat dissipation, but may also result in higher manufacturing costs.

6. On the other hand, thinner PCBs are lighter and more cost-effective, but may be more susceptible to bending or warping.

7. In high-frequency applications, the thickness of the PCB can also affect signal integrity and impedance control.

8. Therefore, PCB designers should carefully evaluate the specific requirements of the application and select the most suitable board thickness accordingly.

9. Additionally, the selection of board thickness should also take into account the compatibility with other components and the manufacturability of the PCB.

10. Overall, a well-informed decision on PCB board thickness is essential for ensuring the overall functionality and performance of the final PCB product.

PCB board thickness

1. Conventional thickness: 1.0mm, 1.6mm, 2.0mm

These thicknesses are usually used for general applications, such as consumer electronics, smart homes, industrial controls, and so on. These applications do not require particularly high mechanical strength or electrical conductivity, so conventional-thickness PCBs can be used.

2. Ultra-thin plate thickness: 0.4mm, 0.6mm

The thickness of these ultra-thin plates is usually used for lightweight and miniaturized electronic products, such as smartwatches, smartglasses, and smart wearable devices. These products require very lightweight PCBs, so using ultra-thin PCB board thickness can meet the demand.

3. High-strength plate thickness: 2.4mm, 3.0mm

These high-strength plate thicknesses are typically used for some industrial and military applications, such as aerospace, railway transportation, military equipment, and so on. These applications require PCBs to have very high mechanical strength and durability, so using PCBs with high-strength board thickness can meet the requirements.

In summary, the selection of PCB board thickness needs to be determined based on specific application requirements. When selecting the thickness of a PCB board, multiple factors such as mechanical strength, conductivity, and cost need to be considered to ensure the performance and reliability of the PCB. At the same time, it is also necessary to pay attention to the thickness limit of the PCB board to ensure that the designed PCB can be manufactured and assembled.

Factors affecting PCB thickness

1. Copper thickness

The total thickness of a PCB is affected by the thickness of the copper layer it contains. A thicker copper layer, such as 2 ounces or 3 ounces of copper, contributes more to the total thickness than a thinner copper layer. The thickness of the copper layer used is determined by the current that the circuit board needs to pass through.

2. Substrate material

The choice of substrate will significantly affect PCB board thickness. Different materials have different thicknesses. For example, compared to rigid PCB substrates, flexible printed circuit boards often have thinner substrates. Common substrate materials such as FR-4 have standard thicknesses, but special materials may have unique thickness characteristics.

3. Number of PCB layers

For single-layer PCBs, their thickness is smaller compared to multi-layer printed circuit boards. The standard threshold for PCB thickness usually accommodates 2-6 layers of PCB. However, for layers of 8 or more, the thickness may not be within the standard range. Each additional layer will increase the total thickness of the PCB.

4. Signal type

The thickness of a PCB is influenced by the type of signal it carries. For example, PCBs carrying high-power signals require thicker copper layers and wider wiring, which are much thicker than circuit boards operating in low-power environments. On the other hand, high-density boards with complex signals typically use laser micropores, fine marks, and thin high-performance materials, making them traditionally thinner than other types of boards.

5. Type of through-hole

PCB via playback is crucial for wiring across different layers of the circuit board, achieving a more compact and efficient design. Multiple types of vias can be used for different applications, including through, micropores, blind holes, and through burial.

The selection and density of vias used in PCB design will affect the required board thickness. For example, using micropores on thinner PCB boards is feasible because they are smaller in size and very suitable for high-density connections. Understanding the characteristics and limitations of different through-hole types is crucial for determining the appropriate PCB board thickness for a given design.

6. Operating conditions

Operating conditions are another important factor affecting PCB board thickness. For example, under challenging operating conditions, such as harsh environments, thin or flexible plates may not be the most suitable choice. Similarly, when exposed to high currents, thicker copper traces have poor thermal stability, making them less suitable for temperature changes or high current environments.

The primary consideration when customizing PCB thickness

1) Weight: Thicker plates are usually better than thinner plates because thinner plates are often more brittle and prone to breakage unless specific applications require thin plates.

2) Flexibility: Compared to thick plates, thin plates provide greater flexibility, but they are also more prone to cracking. Thick plates, on the other hand, are less flexible but heavier.

3) Space limitations: Device size and available space to accommodate PCBs can affect the selection of board thickness. Larger devices can accommodate thicker circuit boards, while smaller devices require smaller circuit boards.

4) Connectors and components: The types of connectors and components used in PCB design may have specific thickness requirements to consider.

5) Impedance: The thickness of a PCB board is directly related to the thickness of the dielectric material used, which plays an important role in achieving appropriate impedance characteristics. Optimal signal integrity and performance can be achieved in a PCB by ensuring that the board thickness matches the expected impedance.

PCB board thickness is one of the important factors to consider when manufacturing printed circuit boards, as it affects conductivity, resistance, and PCB performance. In the PCB industry, there is no unified standard for PCB board thickness, but some thicknesses are preferred and commonly used by many manufacturers.