Understanding Flexible Printed Circuit Board (FPC) Impedance

FPC impedance is a key factor influencing circuit performance, consisting of resistance and reactance that hinder alternating current flow. Impedance, denoted by Z, is a complex number with real (resistance) and imaginary (reactance) parts. Capacitive reactance obstructs current flow due to capacitance, while inductive reactance does so due to inductance. Together, these effects are known as reactance.

The Role of Impedance in FPC Circuit Boards

- Impedance, measured in ohms, is crucial in determining current flow in FPC circuit boards with resistance, inductance, and capacitance.

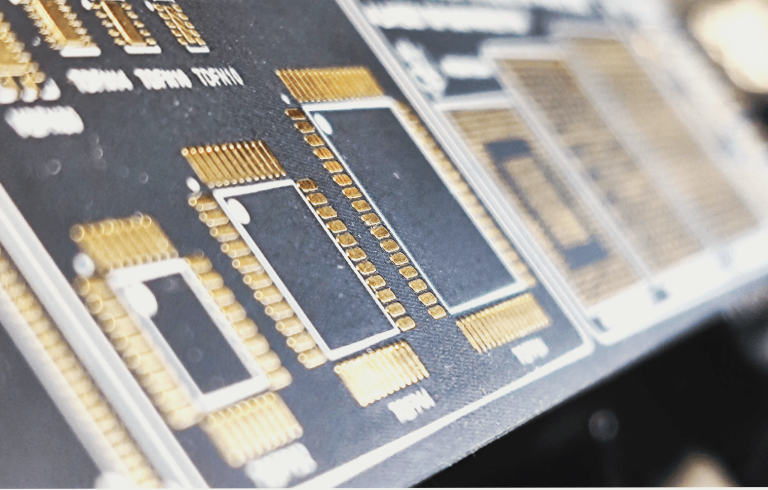

- Various types of impedance like characteristic impedance, differential impedance, odd mode impedance, even mode impedance, and common mode impedance need consideration during production.

Purpose of FPC Impedance

- Ensuring good conductivity and signal transmission performance during electronic component installation is essential. Lower impedance is preferred, with resistivity below 1 ohm:10-6 per square centimeter.

- Materials with low resistivity are vital throughout production to maintain desired impedance levels, meet quality standards, and ensure effective circuit operation. Close monitoring of production steps is necessary to meet impedance requirements.