1. Aluminum printed circuit boards possess excellent heat dissipation capabilities for electronic products. Aluminum PCBs are among the most commonly used types, featuring a standard FR4 laminate and an aluminum core. The circuit board effectively dissipates heat through its thermal envelope, making it ideal for applications requiring tight tolerances and high power.

2. **Three layers in aluminum PCB**

Compared to other PCB types, aluminum PCBs differ significantly in design and manufacturing. The printed circuit board comprises three main layers.

**Circuit layer**—The circuit layer of the aluminum PCB is made of copper foil, available in various weights ranging from 1 to 10 ounces.

**Thermal insulation layer**—The thermal insulation layer consists of ceramic polymer, which offers excellent heat resistance and viscoelasticity. This layer is crucial, as it protects the circuit board from potential mechanical and thermal stresses.

**Base layer**—The base layer is crafted from aluminum alloy substrate, making these PCBs ideal for through-hole technology due to the aluminum’s properties.

3. **How to make aluminum PCBs?**

During the manufacturing process of aluminum PCBs, a thin dielectric layer is added between the circuit layer and the base layer. This dielectric layer is both electrically insulating and thermally conductive. After adding the dielectric, the circuit layer or copper foil is etched to achieve the desired pattern. The metal base of the circuit board efficiently dissipates heat, aided by the thin dielectric layer.

4. **What are the application areas of aluminum PCBs?**

Aluminum printed circuit boards are among the most widely used circuit boards available. They can be applied in various sectors, such as:

Signal beacons, surgical lighting tools, power transmission systems, high-power scanners, automotive dashboards, interior lighting, power converters, medical operating room lighting, landscape lighting, and taillight components.

5. This overview provides fundamental insights into aluminum circuit boards and their applications. Next, we will discuss the different types of aluminum PCBs and their advantages.

6. **What are the different types of aluminum PCBs?**

As previously mentioned, the type of aluminum circuit board selected largely depends on its intended application. The three main types of aluminum PCBs are:

**Through-hole aluminum PCB**—In this type, aluminum is pre-drilled, after which the dielectric is backfilled into the holes.

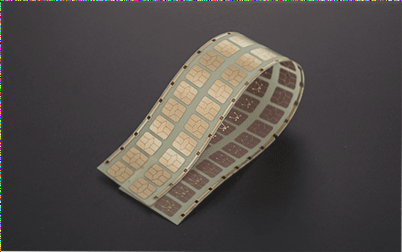

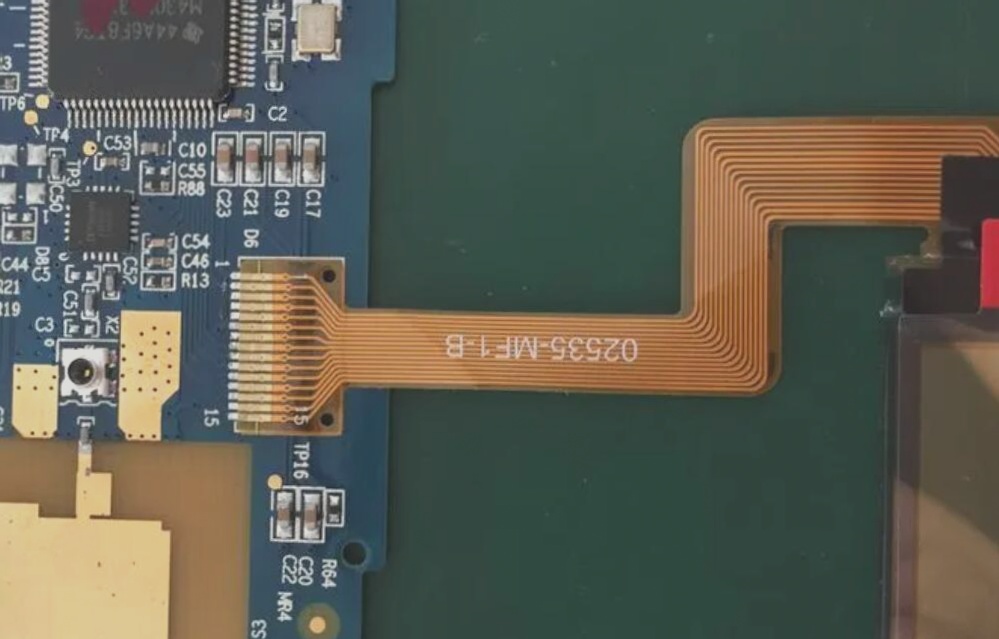

**Flexible Aluminum PCB**—These PCBs utilize a flexible dielectric, offering high flexibility, thermal conductivity, and electrical insulation. When combined with aluminum materials, they can be formed into various shapes, eliminating the need for costly connectors and fixtures.

**Hybrid Aluminum PCB**—Commonly used in RF applications, these aluminum PCBs provide superior thermal performance compared to standard FR4 products.

7. **What makes aluminum PCBs so popular in various applications?**

The numerous advantages of aluminum PCBs contribute to their popularity across a range of applications. Here are some key benefits:

**Lightweight**—Aluminum is an exceptionally light metal, enhancing the strength and flexibility of the PCB.

**Heat dissipation**—When critical components on the circuit board are exposed to high temperatures, they risk damage. Therefore, materials capable of dissipating heat are essential. Aluminum effectively channels heat away from vital parts, protecting them from potential damage.