Sure, here’s the revised version:

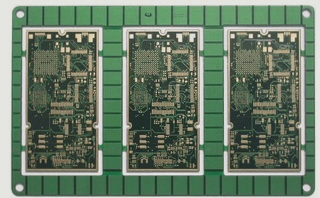

What is the role of PCB solder mask opening? Before delving into the concept of PCB solder mask opening, let’s first grasp the essence of solder mask. The term “solder mask” pertains to the protective coating applied on specific areas of a printed circuit board (PCB), typically designated for green oil application. PCB solder mask opening refers to the intentional exposure of copper pads, ensuring they remain uncovered by solder mask ink, thereby necessitating their protrusion from the board, as illustrated below:

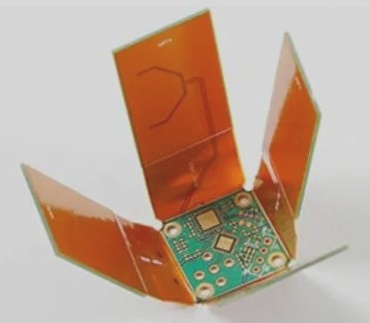

What is the function of the PCB solder mask window? If it is a double-sided circuit board in the design, there will be a solder mask layer printed on both sides of the board. The function of this layer of ink is to prevent oxidation of the circuit board and protect it, and facilitate subsequent SMT soldering. PCB solder mask opening means that the copper skin around the aperture of the circuit board must not be covered by ink. If the solder mask is covered, it will not be possible to measure the corresponding signal. Only by leaking the copper skin of the aperture to the surface can it effectively increase the distance. The wire thickness increases the passing current limit. As a professional FPC soft board manufacturer, WellCircuits Limited is so honored to have worked together with many of you. At WellCircuits Limited, we are always more than ready to assist our new customers in any way we can. Please feel free to contact us at any time if you have any questions.

What is the role of PCB solder mask opening? Before delving into the concept of PCB solder mask opening, let’s first grasp the essence of solder mask. The term “solder mask” pertains to the protective coating applied on specific areas of a printed circuit board (PCB), typically designated for green oil application. PCB solder mask opening refers to the intentional exposure of copper pads, ensuring they remain uncovered by solder mask ink, thereby necessitating their protrusion from the board, as illustrated below:

What is the function of the PCB solder mask window? If it is a double-sided circuit board in the design, there will be a solder mask layer printed on both sides of the board. The function of this layer of ink is to prevent oxidation of the circuit board and protect it, and facilitate subsequent SMT soldering. PCB solder mask opening means that the copper skin around the aperture of the circuit board must not be covered by ink. If the solder mask is covered, it will not be possible to measure the corresponding signal. Only by leaking the copper skin of the aperture to the surface can it effectively increase the distance. The wire thickness increases the passing current limit. As a professional FPC soft board manufacturer, WellCircuits Limited is so honored to have worked together with many of you. At WellCircuits Limited, we are always more than ready to assist our new customers in any way we can. Please feel free to contact us at any time if you have any questions.