Flexible Circuit Boards: Evolution and Applications

- Early flexible circuit boards, known as soft boards, were initially used in small electronic devices and for connecting rigid boards.

- By the late 1970s, soft boards became prevalent in various electronic products like computers, cameras, printers, car stereos, and hard disk drives.

- Today, the Japanese flexible PCB market focuses on consumer electronics, while the US has shifted from military to consumer applications.

- Soft boards serve four main functions: Lead Line, Printed Circuit, Connector, and Functional Integration.

- They are utilized in computers, consumer appliances, and automotive systems.

Copper Clad Laminator (CCL)

- Copper foil comes in two types: E.D. (Electrodeposited) and R.A. (Rolled Annealed) copper.

- R.A. copper, though pricier, offers superior flexibility compared to the less expensive but fragile E.D. copper.

- Soft boards predominantly use R.A. copper for their copper foil.

Adhesive and Polyimide (Kapton) Layer

- Adhesives are primarily acrylic or modified epoxy, crucial for bonding components on the board.

- Kapton, a polyimide film, provides high-temperature resistance, chemical resistance, and excellent electrical insulation.

- It meets specific soldering requirements and ensures stable chemical properties.

Features of Flexible Circuit Boards

- High flexibility allows for three-dimensional wiring and adaptability to spatial constraints.

- Resistant to extreme temperatures, flames, and electrostatic interference.

- Maintains stable chemical properties for high reliability and stability.

- Advantages include reduced product size, weight, costs, and enhanced functionality.

Polyimide Resin

- Polyimide resin, a heat-resistant material, is versatile and widely used in sensors and PCBs.

- Considerations for PCB applications include heat resistance, formability, mechanical properties, and cost.

- Usage is expected to increase, especially in multilayer PCBs.

Conductors in PCBs utilize thin copper foil, essential for various electronic applications.

PCB Components

-

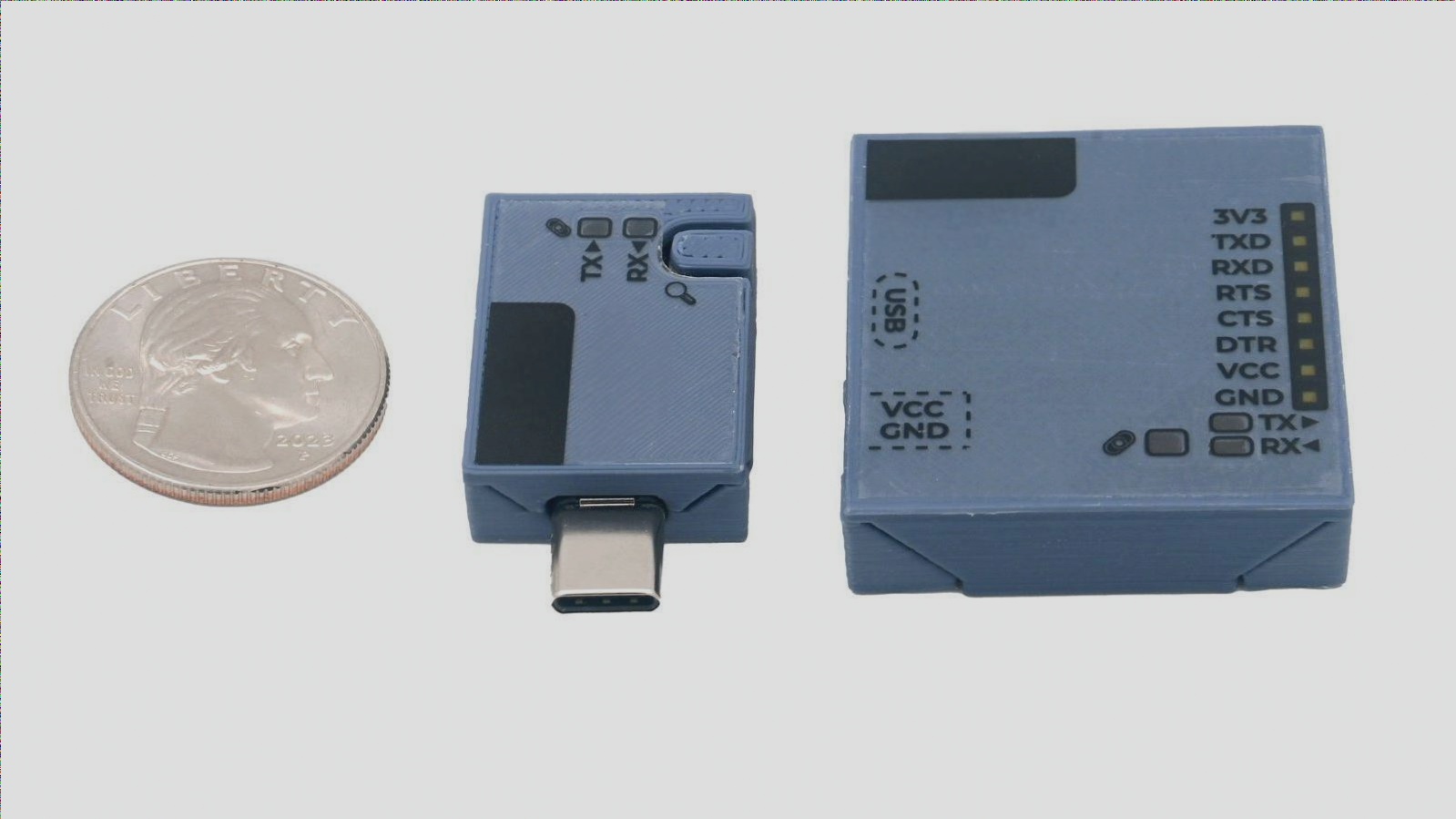

Connectors

Connectors play a crucial role in establishing affordable connections between hard boards in a wide range of electronic devices.

-

Multifunctional Integration

Integrating hard board lead wires and connectors in computer systems, cameras, and medical equipment enhances functionality and efficiency.