1. A sensor is a detection device that senses measured information and converts it into electrical signals or other required forms of output according to specific rules. This facilitates information transmission, processing, storage, display, recording, and control.

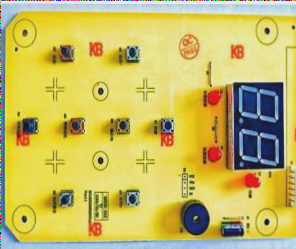

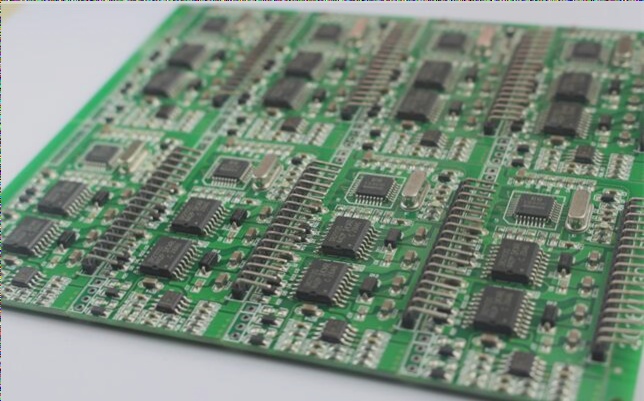

2. Integrated sensors are manufactured using standard techniques for silicon-based semiconductor integrated circuits. Some circuits for initial signal processing are also integrated on the same chip, such as the now well-developed MEMS sensors.

3. Thick film sensors are made by applying a slurry of the corresponding material onto a ceramic substrate, typically composed of Al2O3. Subsequently, heat treatment is applied to form the thick film.

4. Thin film sensors are created by depositing a thin film of the corresponding sensitive material onto a dielectric substrate. In hybrid processes, part of the circuit may also be fabricated on the substrate.

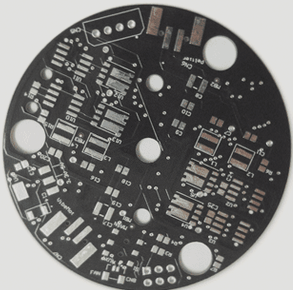

5. Ceramic sensors are produced using standard ceramic technology or some variant processes (sol, gel, etc.). After suitable preparatory operations, the formed elements are sintered at high temperatures.

6. Thick film and ceramic sensors share many common characteristics. Thick film technology can be viewed as a variation of ceramic technology in some aspects.

7. When selecting sensors based on sensitivity, frequency response, linear range, stability, and accuracy, stability is closely related to the substrate. While the manufacturing process primarily influences sensitivity and accuracy, stability is paramount. Ceramic circuit boards offer excellent stability, provided the manufacturing process meets the required standards.

8. Currently, the most advanced manufacturing process for ceramic PCBs is LAM technology. Laser Activation Metallization (LAM) combines ceramic and metal ions using a high-energy laser beam, ensuring firm bonding.

9. However, many domestic (Chinese) sensor manufacturers, primarily small and medium-sized, still utilize thin film technology with FR-4 substrates. These sensors have a short service life and poor stability, making them vulnerable in slightly adverse environments.

10. Achieving international standards for sensors will require significant effort. WellCircuits stands out as a professional entity capable of meeting this challenge.

11. Sensors and ceramic PCBs are extensively used in developed countries. The current technological gap poses limitations on our country’s development. Upgrading sensor circuit boards depends on mass-production factories fostering technical innovations to enhance competitiveness and enable the domestic sensor industry to catch up with global standards.

2. Integrated sensors are manufactured using standard techniques for silicon-based semiconductor integrated circuits. Some circuits for initial signal processing are also integrated on the same chip, such as the now well-developed MEMS sensors.

3. Thick film sensors are made by applying a slurry of the corresponding material onto a ceramic substrate, typically composed of Al2O3. Subsequently, heat treatment is applied to form the thick film.

4. Thin film sensors are created by depositing a thin film of the corresponding sensitive material onto a dielectric substrate. In hybrid processes, part of the circuit may also be fabricated on the substrate.

5. Ceramic sensors are produced using standard ceramic technology or some variant processes (sol, gel, etc.). After suitable preparatory operations, the formed elements are sintered at high temperatures.

6. Thick film and ceramic sensors share many common characteristics. Thick film technology can be viewed as a variation of ceramic technology in some aspects.

7. When selecting sensors based on sensitivity, frequency response, linear range, stability, and accuracy, stability is closely related to the substrate. While the manufacturing process primarily influences sensitivity and accuracy, stability is paramount. Ceramic circuit boards offer excellent stability, provided the manufacturing process meets the required standards.

8. Currently, the most advanced manufacturing process for ceramic PCBs is LAM technology. Laser Activation Metallization (LAM) combines ceramic and metal ions using a high-energy laser beam, ensuring firm bonding.

9. However, many domestic (Chinese) sensor manufacturers, primarily small and medium-sized, still utilize thin film technology with FR-4 substrates. These sensors have a short service life and poor stability, making them vulnerable in slightly adverse environments.

10. Achieving international standards for sensors will require significant effort. WellCircuits stands out as a professional entity capable of meeting this challenge.

11. Sensors and ceramic PCBs are extensively used in developed countries. The current technological gap poses limitations on our country’s development. Upgrading sensor circuit boards depends on mass-production factories fostering technical innovations to enhance competitiveness and enable the domestic sensor industry to catch up with global standards.