PCB Design Considerations for Connecting Multiple Devices

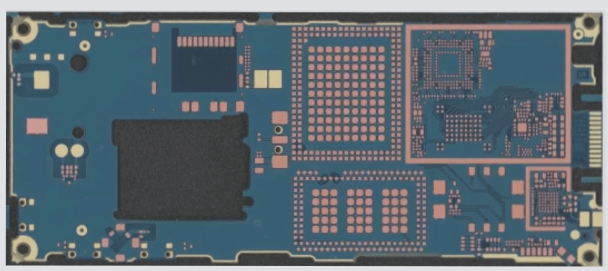

When designing a PCB to connect multiple devices like FLASH, SDRAM, and other peripherals using buses (address, data, command), the wiring method employed plays a crucial role in signal integrity. Different topologies can impact signal quality, with a star topology often being preferred for synchronizing signal transmission and reflection delays. However, the specific characteristics of the signal topology and the complexity of the wiring must be considered before implementation.

High-speed signals, such as those between DSP and SDRAM, require special attention to waveform integrity. The choice of wiring topology, whether star, daisy chain, or others, should be made based on the specific requirements of the PCB design and signal characteristics.

Automatic vs. Manual Wiring for PCBs Operating Above 30 MHz

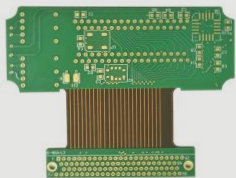

When operating at frequencies above 30 MHz, the choice between automatic and manual wiring depends on the software’s routing capabilities. While automatic routing can be more efficient for certain tasks, manual routing may be preferred for specific connections or checks. The composition of PCB copy boards, typically resin and glass cloth mixtures, affects dielectric constants and material thickness.

New PCB materials, like ultra-thick backplanes or low-loss RF boards, offer specialized solutions for different design requirements.

Ground Connections in PCB Design

Separating ground connections into protective ground, signal ground, digital ground, and analog ground is crucial for EMC considerations. Noise from digital components can interfere with signals, especially analog ones, if not properly managed. The separation of ground connections helps mitigate ESD static discharge and noise emission issues.

Routing Clock Lines and Ground Wire Shields

When routing clock lines of varying frequencies, conducting a signal integrity analysis and following routing guidelines are essential. The decision to include shielded ground wires depends on crosstalk/EMI conditions present on the board, as incorrect implementation could worsen the situation.

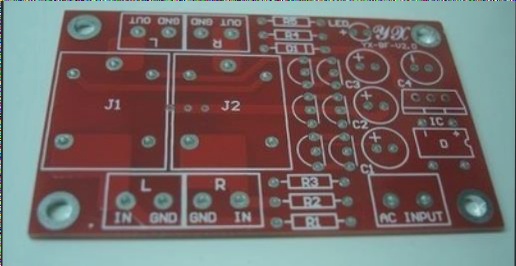

Routing Traces on Single-Layer PCBs

When manually routing a single-layer PCB, it is recommended to place the traces on the opposite layer of where the components are positioned. For example, if the components are placed on the top layer, then the routing should occur on the bottom layer.

For any PCB manufacturing requirements or inquiries, feel free to reach out to us.

- If you need assistance with PCB manufacturing, contact us.