PCBA Processing Procedure and Key Precautions

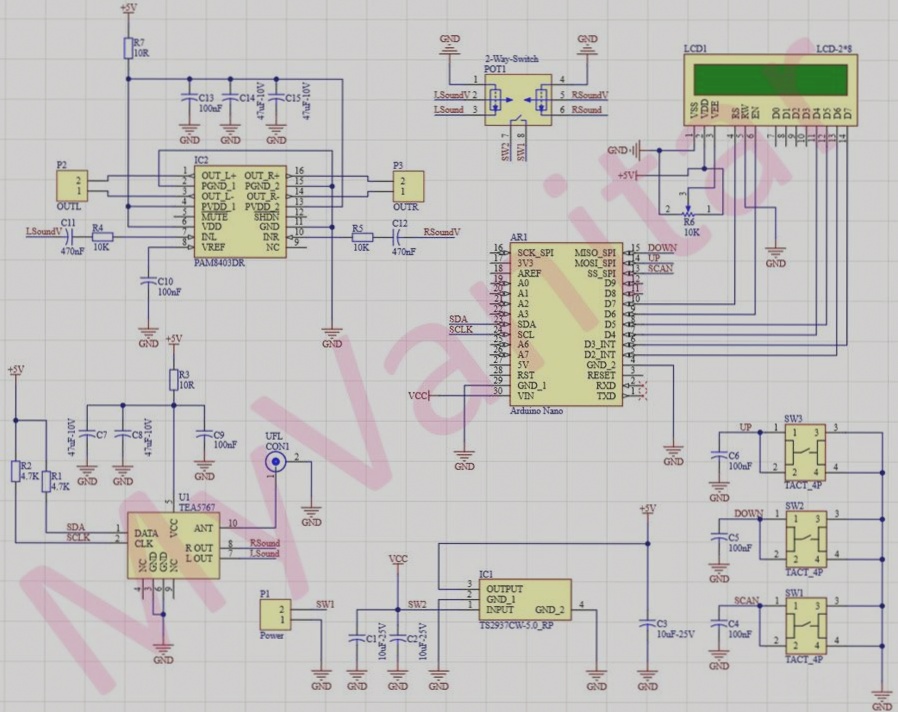

- PCBA processing begins with generating process and coordination files from provided Gerber files and BOMs.

- Materials are prepared meticulously before production to ensure adherence to specifications.

- Staff must wear anti-static gloves, and proper organization of PCBA substrates is crucial to prevent damage.

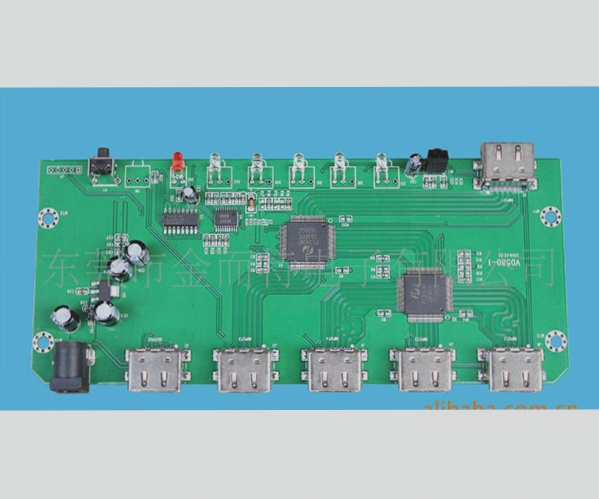

PCBA Processing Flow

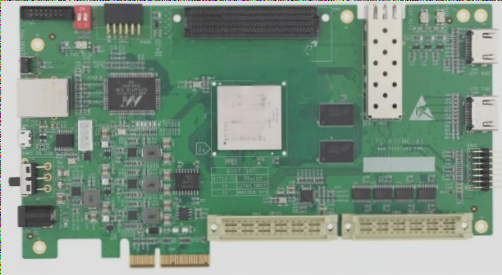

- Creation of process files and SMT coordinate files based on customer’s data.

- Verification of materials, order compilation, and PMC production plan confirmation.

- Execution of SMT programming and initial board production for accuracy verification.

- Utilization of SMT methods for laser-cut steel meshes creation.

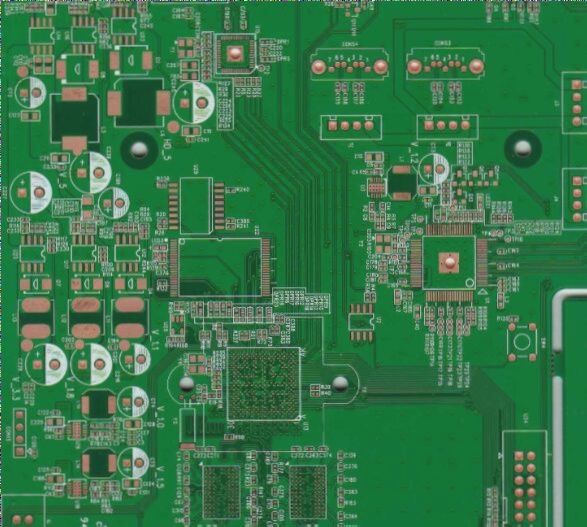

- Ensuring uniform and appropriate solder paste printing for consistency.

- Component mounting using SMT placement machine with online AOI inspection.

- Establishment of optimal reflow soldering furnace temperature curve for effective soldering.

- IPQC inspection to meet processing technology requirements.

- DIP plug-in process with wave soldering for connections.

- Post-furnace processes including lead trimming, inspections, and surface cleaning.

- Comprehensive QA testing to guarantee processing quality.

PCBA Processing Precautions

- Warehouse personnel should wear anti-static gloves and ground work surfaces during material distribution and IQC testing.

- Utilize anti-static work surfaces and containers for components and products storage.

- Repair any misalignment of plug-in components after the soldering process.

- Exercise caution to avoid excessive solder usage during PCBA soldering to prevent short circuits.

- Properly organize PCBA substrates and use electrostatic bags for stacking to prevent damage.