The Ultimate Guide to PCB Milling

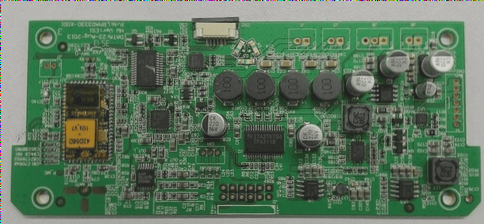

Printed circuit boards (PCBs) play a crucial role in the functionality of electronic devices used in homes and industries. PCB milling, also referred to as isolation milling, is a fundamental process for producing durable and high-quality PCB boards. Discover the importance of PCB milling, design considerations, the milling process, and more.

Essential Insights on PCB Milling:

- PCB milling is a subtractive technique that entails the removal of copper traces to form pads, signal tracks, and configurations.

- Unlike chemical etching, PCB milling eliminates the use of harmful chemicals, making it a safer and eco-friendly option.

- There are numerous advantages to PCB milling, particularly for creating unique structures and prototypes.

- For rapid PCB fabrication without chemical processes, consider CNC device prototyping.

Benefits of PCB Milling:

One of the key benefits of PCB milling is the eco-friendly aspect of the production process. While chemical etching remains prevalent, the chemical-free nature of PCB milling is a standout feature.

WellCircuits PCB Assembly Services:

WellCircuits PCB Assembly, with extensive experience in the PCB milling sector, provides exceptional services for high, medium to low volume PCB assembly, and quick-turn prototypes. Our primary focus is on customer satisfaction, ensuring efficient fulfillment of your requirements. Reach out to us today for competitive pricing and top-notch PCB milling solutions.

For all your PCB milling needs, do not hesitate to contact us. We are here to assist you promptly!